Valve Automatic Machining kab

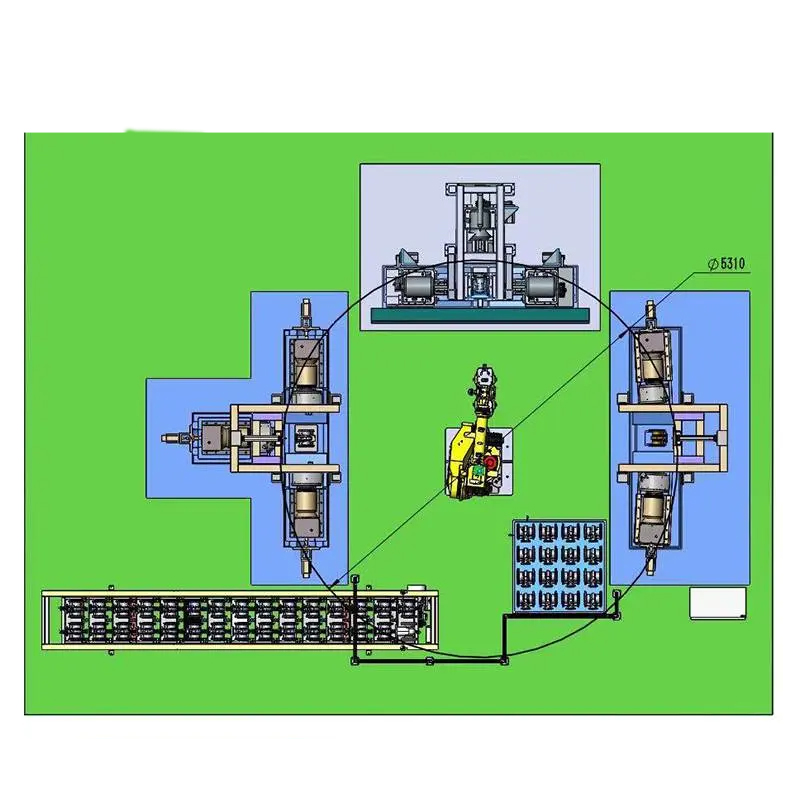

Tag nrho layout

1: Cov khoom siv automation no yog tsim los ntawm 6-axis machining chaw, ntau lub tshuab machining chaw, thiab plaub-axis machining chaw (cov khoom sib txawv tuaj yeem tsim raws li cov neeg siv khoom xav tau); ib tug neeg hlau yog configured rau loading thiab unloading.

2: Qhov kev teeb tsa ntawm thaj chaw ua haujlwm yog ib puag ncig, thiab tsuas yog lub qhov hluav taws xob thiab qhov hluav taws xob tau teeb tsa rau ntawm txoj haujlwm sab saud thiab sab qis, uas yog siv rau kev thauj khoom thiab tshem tawm lub cev valve.

3: Kev thauj khoom thiab thauj khoom tuaj yeem pub los ntawm feeder lossis lub zeem muag neeg hlau.

Cov ntsiab lus automation ib nrab

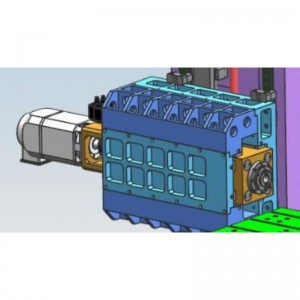

1.Lub chaw thau khoom thiab tshem tawm cov neeg hlau tuaj yeem xaiv cov khoom lag luam thoob ntiaj teb lossis hauv tebchaws kom tau raws li kev mus ncig thiab kev thauj khoom ntawm qhov tsis siv neeg thauj khoom thiab thauj khoom;

2.Cov khoom siv tau txais kev tiv thaiv tag nrho, nrog cov khoom siv tshem tawm plua plav, lub qhov rooj tiv thaiv tau raug thawb thiab rub tawm raws li cov lus qhia, thiab cov cuab yeej tau txiav thiab txiav.

3.Tom qab ua tiav, cov khoom ua haujlwm tau ncaj qha tso rau ntawm txoj siv conveyor los ntawm tus neeg hlau thiab thauj mus rau cov txheej txheem tom ntej.

4.Tus neeg hlau gripper yog tsim los nrog ob lub grippers, uas tuaj yeem siv ua ke los ua kom tiav qhov chaw thau khoom thiab tshem tawm ntawm lub tshuab.