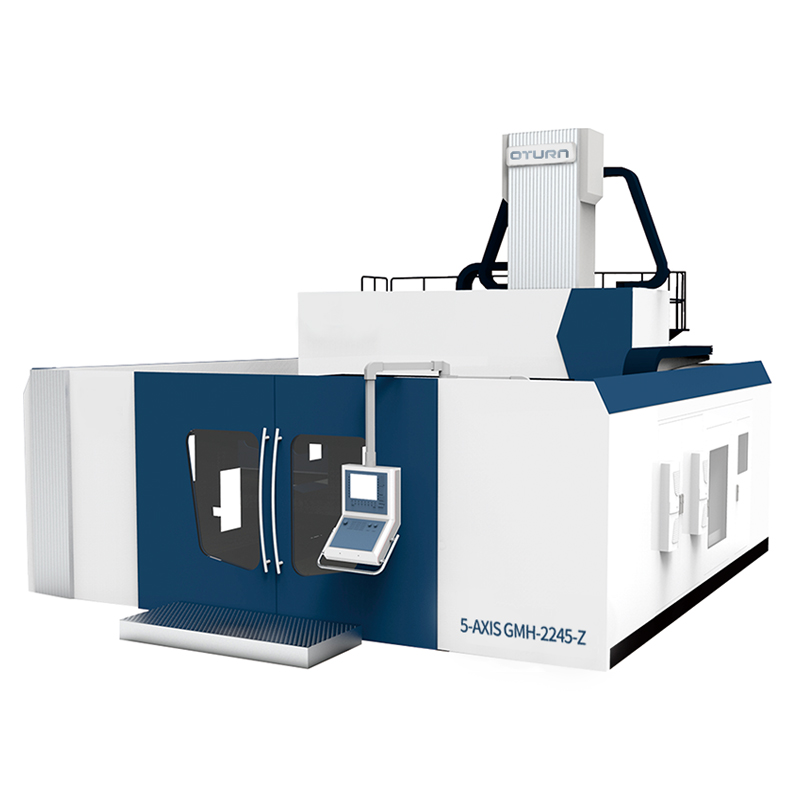

CNC Heavy-duty choj 5-axis GMH-2245-Z

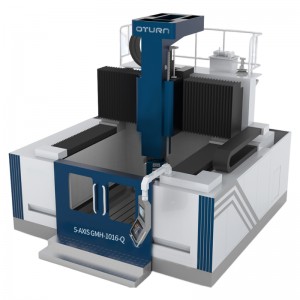

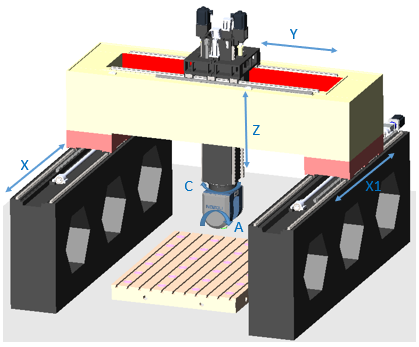

Taw qhia ntawm 5-axis tshuab

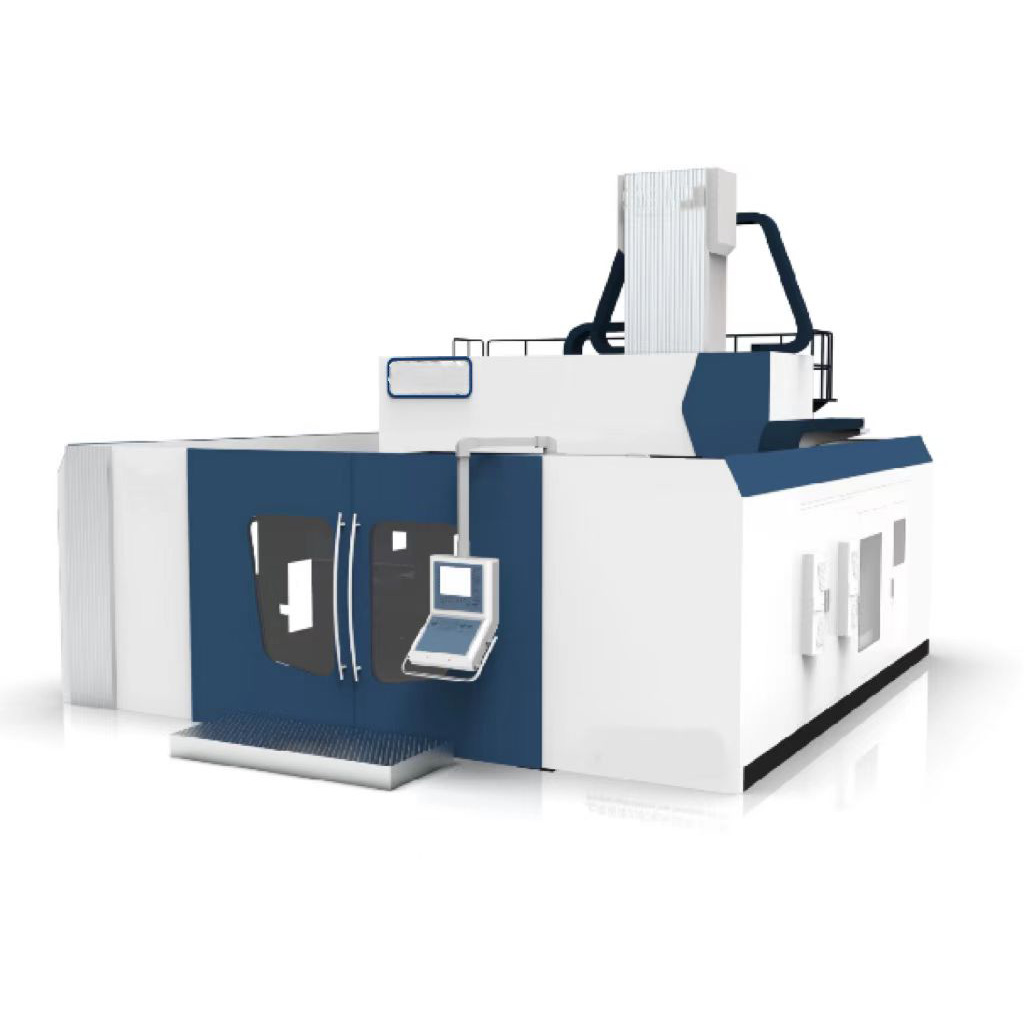

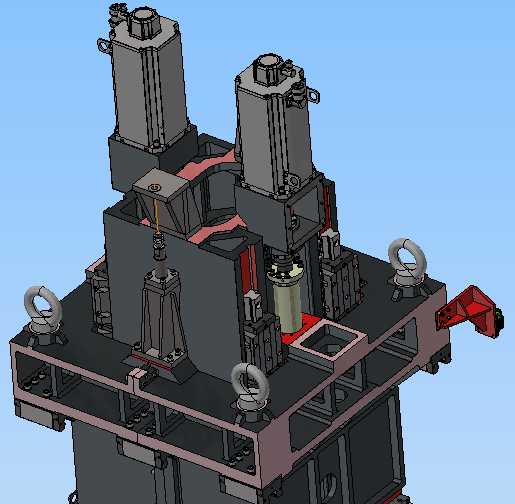

Heavy-duty choj-hom tsib-axis gantry machining chaw, tag nrho layout txais ib tug elevated choj-hom gantry qauv, tag nrho cov thermal symmetry thiab spindle system box-hauv-box qauv, uas daws qhov teeb meem ntawm cov tsoos choj-hom. high-speed tsib-axis gantry machining chaw.Lub ram adopts sab dai ntawm lub nqaj los tsim cov ntxaiv Qhov tshwm sim ntawm qhov chaw khiav haujlwm tuaj yeem txo qhov thermal hloov pauv los ntawm kev hloov pauv ntawm qhov kub thiab txias hauv lub rhiav thiab txhim kho qhov tseeb ntawm lub tshuab;thiab qhov thermally symmetrical tsim no ua rau lub tshuab tsis tshua muaj kev cuam tshuam rau qhov chaw hnyav.

Nrog high-precision tsib-axis milling lub taub hau, lub ntsiab ncej txais kev kub ceev ob chav viav vias taub hau, uas tuaj yeem paub txog kev ua haujlwm siab milling thiab high-speed tiav nyob rau hauv tsib-axis txuas, thiab tuaj yeem paub meej kev tswj ntawm machining duab, nrog siab. efficiency, siab precision, stability thiab kev cia siab.

High spindle ceev, siab precision thiab zoo precision tuav, roj lubrication, yuam kev txias.

Lub ntsiab axes ntawm qhov hnyav-duty choj-hom tsib-axis gantry machining chaw yog muab faib ua linear axes X-axis, Y-axis, Z-axis, teb axis C-axis, A-axis., kev ua tiav ntawm kev sib sib zog nqus drilling, kab noj hniav so thiab taper ntawm qhov chaw nyuaj, nrog rau qhov teeb meem ntawm kev ua haujlwm zoo thiab kev ua haujlwm ntawm cov khoom tshwj xeeb zoo li qhov nyuaj.

Cov qauv kev taw qhia yog lub teeb yuag, txo qhov kev tsav tsheb ntawm lub pob ntsia hlau, txo qhov hnav ntawm lub pob ntsia hlau thiab cov lus qhia tawm, thiab ua raws li kev txhim kho qhov tseeb;

Cov qauv ntawm viaduct kuj ua rau kom qhov nruj ntawm cov khoom thauj khoom ntawm lub tshuab, uas tuaj yeem zam qhov tshwm sim ntawm kev tshee yooj yim tshwm sim thaum lub nqaj txav nrawm thiab cov ntxaiv txav ntawm kev kub ceev;

Ua ke nrog ob sab caj npab AC tsib-axis lub taub hau, cov hlau nplaum ruaj khov high-torque torque lub cev muaj zog mechanism tuaj yeem ua tau raws li qhov xav tau siab tshaj plaws ntawm qhov tseeb, lub zog thiab cov lus teb tsis zoo, tshem tawm cov khoom siv sib kis, kev saib xyuas yooj yim, muaj ntau yam, thiab cov qauv tsawg dua.

Kev sib hloov ntau yam ntawm A-axis yog ± 110 °, thiab kev sib hloov ntawm C-axis yog ± 270 °, uas zoo kawg nkaus paub txog kev hloov pauv ntsug thiab kab rov tav;

Lub machining raug ntawm cov khoom ncav cuag 5μ;nws tuaj yeem ua cov ntaub ntawv xws li titanium alloy;cov txheej txheem yog nyob ze rau cov thawj coj thoob ntiaj teb;

Ua ke nrog tag nrho kaw-voj lub kaum sab xis encoder nrog siab repeatability, qhov tseeb ntawm qhov chaw ntawm A thiab C axes tuaj yeem ncav cuag ± 5arc sec, thiab qhov rov ua dua ntawm A thiab C axis positioning tuaj yeem ncav cuag ± 3.5arc sec, uas tsis tsuas yog paub txog siab. -precision machining, tab sis kuj zam cov kaum sab xis.Kev teeb tsa debug.

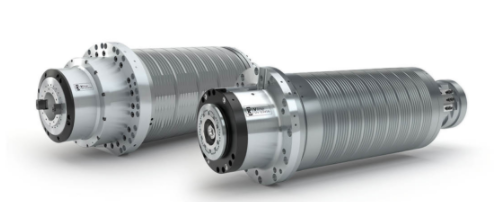

Ob sab caj npab tsib-axis taub hau

Lub tsib-axis gantry machining chaw tuaj yeem nruab nrog peb qhov sib txawv motorized spindles: siab, nruab nrab thiab qis.Qhov siab tshaj plaws ceev tuaj yeem ncav cuag 18000rpm, lub zog ntxaiv yog 35KW, thiab qhov siab tshaj plaws torque tuaj yeem ncav cuag 118Nm.Cov cuab yeej tuav yog HSK-A63;lub cuab yeej yog hydraulically txhawb nqa, thiab lub cuab yeej clamping system muaj lub zog tuav loj;lub cuab tam ntev muaj dej los ntawm qhov chaw ntawm lub spindle kom txias lub machining point, uas ntxiv txhim kho qhov machining raug;lub txiav quab yuam yog loj, txiav efficiency siab, lub sij hawm ua yog luv, thiab lub zog ntau lawm efficiency yog zoo, yeej yuav tsum tau them rau tag nrho cov lag luam xav tau kev pab!

Ob sab caj npab tsib-axis taub hau fused nrog cov hlau nplaum ruaj khov high-torque torque lub cev muaj zog mechanism;

Nrog siab precision kaum encoder;

Thiab ib tug rhiab heev passive clamping system mechanism;

Lub taub hau tsib-axis nrog cov khoom ruaj khov thiab ruaj khov tag nrho cov diav rawg qauv tsim muaj cov qauv compact, zoo rigidity thiab zoo heev yooj;

Nws zoo kawg nkaus daws qhov ntau qhov kev debugging thiab clamping xav tau rau repositioning lub workpiece ntawm complex cov ces kaum, thiab txo qhov kev ua yuam kev.Nws yog tsim rau cov khoom uas muaj qhov nyuaj qhov zoo thiab siab precision yuav tsum.Nws tuaj yeem ua tiav qhov kev ua tiav ntawm qhov chaw nkhaus ntawm ntau lub kaum ntse ntse hauv ib qho clamping thiab txhim kho kev tsim khoom.Tus kheej configuration, high-precision modular tsim, kom ua tiav kev nplua nuj nthuav dav.

Txhawm rau txhim kho qhov kev ua tau zoo ntawm ob sab caj npab AC tsib-axis lub taub hau thiab ua kom nws ua haujlwm ntau dua kev tshawb fawb thiab yoog raws, kev tsim qauv compact, siab-rhiab heev passive clamping system yog saws.Lub passive qigong clamp nrog lub zog ua haujlwm loj muaj kev ruaj ntseg lav ua haujlwm.Thaum lub tshuab ua haujlwm siab poob rau ib qho laj thawj, nws yuav nkag mus rau hauv lub xeev clamp kaw, uas zam qhov teeb meem ntawm lub tshuab tsis ua haujlwm thiab kev sib tsoo thaum ua haujlwm, thiab tuaj yeem tiv thaiv cov cuab yeej zoo dua thiab tsis txhob poob qhov tsis tsim nyog., thiab tag nrho cov nqi system yog qis dua.Lub AC axis muaj kev ruaj ntseg siab, lub zog clamping ntawm A axis tuaj yeem ncav cuag 1680Nm, thiab lub zog clamping ntawm C axis tuaj yeem ncav cuag 2040Nm, uas zoo kawg nkaus paub txog kev ua haujlwm siab.

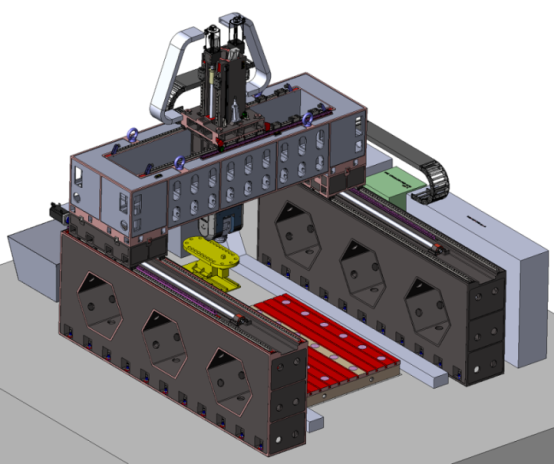

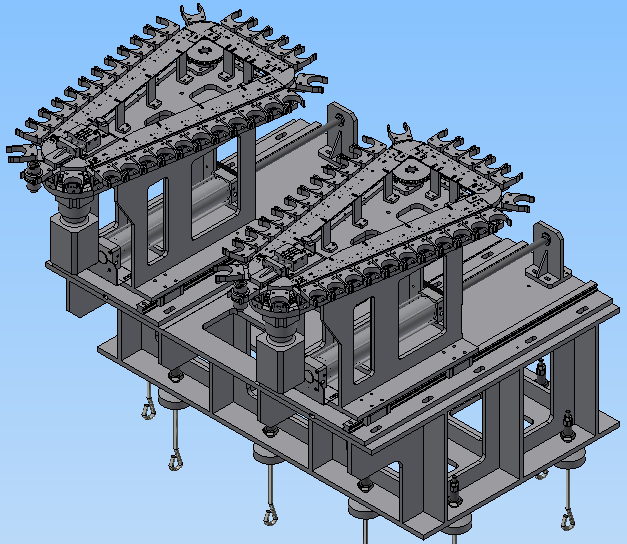

Tus choj hnyav-hom tsib-axis gantry tshuab suav nrog: lub rooj ua haujlwm, kem, kab teeb, lub rooj zaum zawv zawg, lub eeb, thiab lub ram yog castings kom muaj kev ua haujlwm txaus.Rau siab txiav ceev, zoo txiav, siab hlau tshem tawm tus nqi, me me kev nyuaj siab generated los ntawm workpiece txiav, thiab zoo workpiece nto zoo;

Kev txav ceev ceev, tsawg lub sij hawm yuav tsum tau, nruab nrog ob-arm tsib-axis taub hau, ib-lub sij hawm clamping, multi-angle ua, nkhaus nto ua, streamlined ua.

Lub tshuab tag nrho yog nyob ib puag ncig los ntawm kev tiv thaiv, lub tshuab muaj cov nti tshem tawm tsis siv neeg, thiab nruab nrog dej txias ua haujlwm.Lub tshuab muaj qhov zoo nkauj zoo nkauj, ua haujlwm yooj yim thiab tu.

X-axis

X-axis qhia rail daim ntawv: Lub kem yog txawm peem rau nrog plaub 55 hli hnyav-duty roller linear qhia rails.Nws tuaj yeem ua tau raws li qhov xav tau ntawm kev nruj thiab lub zog ntawm lub gantry ncej, thiab tuaj yeem ua tau raws li cov kev ua tau zoo ntawm kev sib txhuam me me, kev txav ceev ceev thiab kev pab lub neej ntev;Txoj kev lubrication: roj lubrication;kab tsheb ciav hlau hom: German INA lossis hom zoo sib xws;

X-axis kis tau tus mob: Tom qab AC servo lub cev muaj zog yog decelerated, nws tsav lub 63 hli txoj kab uas hla precision pob ntsia hlau tig kom paub txog lub hauv ntej thiab nram qab pub ntawm tus swb;Txoj kev lubrication: roj lubrication;Screw hom: Czech KSK lossis tib qib hom;

Nruab nrog ob chav high-precision puv-kaw-voj grating kav;grating kav hom: Spain FAGOR los yog lub teb chaws Yelemees HEIDENHAIN;

Kev tiv thaiv kev tsheb ciav hlau: Cov ntaub thaiv npog tawv tawv yog siv rau kev tiv thaiv kom tsis txhob muaj cov khoom txawv teb chaws nkag mus thiab kis kab mob rau cov kev taw qhia rail.Cov ntaub thaiv npog muaj qhov zoo nkauj zoo nkauj thiab tsim nyog qauv.

Y-Axis

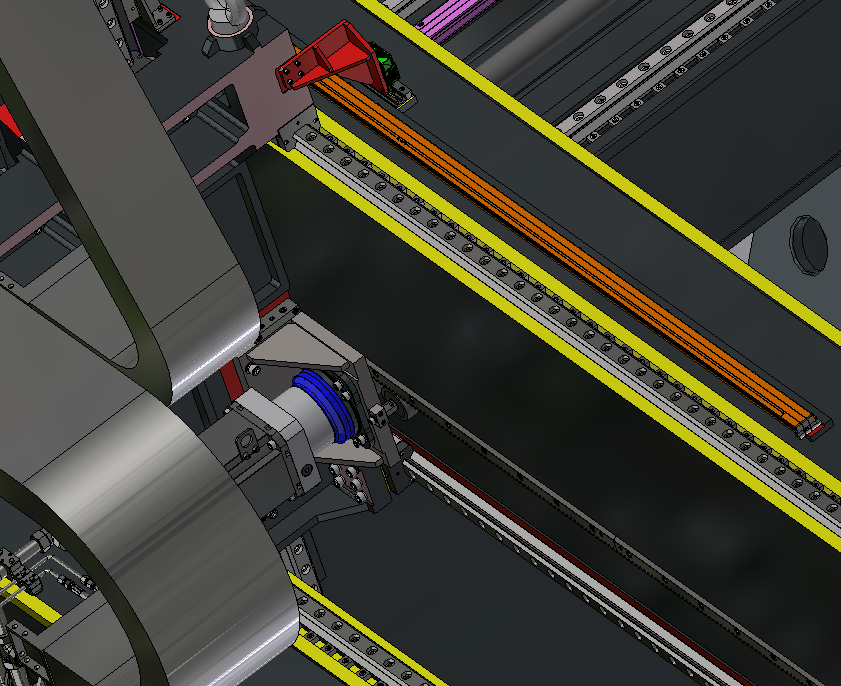

Y-axis qhia rail daim ntawv: lub kem yog txawm peem rau nrog plaub 55 hli hnyav-duty roller linear qhia rails.Nws tuaj yeem ua tau raws li qhov xav tau ntawm kev nruj thiab lub zog ntawm lub gantry ncej, thiab tuaj yeem ua tau raws li cov kev ua tau zoo ntawm kev sib txhuam me me, kev txav ceev ceev thiab kev pab lub neej ntev;Txoj kev lubrication: roj lubrication;kab tsheb ciav hlau hom: German INA lossis hom zoo sib xws;

Y-axis tsav: AC servo lub cev muaj zog yog siv los tsav lub khib thiab pinion kis tau tus mob tom qab deceleration, thiaj li paub txog sab laug thiab txoj cai txav ntawm lub eeb;Txoj kev lubrication: Roj lubrication;Rack hom: German Alpha lossis tib qib hom;

Nruab nrog high-precision puv-kaw-voj grating nplai;grating scale hom: Spain FAGOR los yog lub teb chaws Yelemees HEIDENHAIN;

Kev tiv thaiv kev tsheb ciav hlau: Cov ntaub thaiv npog tawv tawv yog siv rau kev tiv thaiv kom tsis txhob muaj cov khoom txawv teb chaws nkag mus thiab kis kab mob rau cov kev taw qhia rail.Cov ntaub thaiv npog muaj qhov zoo nkauj zoo nkauj thiab tsim nyog qauv.

Z-Axis

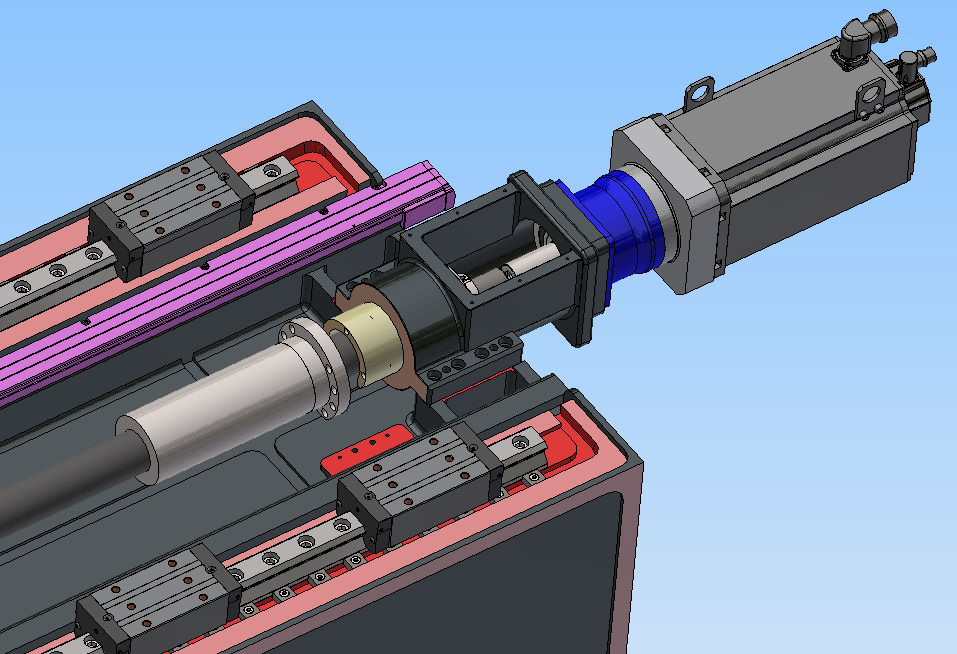

Z-axis qhia rail daim ntawv: lub kem yog txawm peem rau nrog plaub 55 hli hnyav-duty roller linear qhia rails.Nws tuaj yeem ua tau raws li Z-axis lub zog yuav tsum tau ua, thiab tuaj yeem ua tau raws li qhov zoo ntawm kev sib txhuam coefficient me me, kev txav ceev ceev thiab kev pab lub neej ntev;Txoj kev lubrication: roj lubrication;Kab tsheb ciav hlau hom: German INA lossis hom zoo sib xws;

Z-axis kis tau tus mob: AC servo lub cev muaj zog yog siv los tsav lub precision pob ntsia hlau nrog ib txoj kab uas hla ntawm 50mm tig kom paub qhov nce thiab nqis nqa ntawm lub ram;Txoj kev lubrication: roj lubrication;ntsia hlau hom: Czech KSK los yog hom zoo sib xws, nruab nrog ob chav nitrogen sib npaug lub tog raj kheej, sib npaug feem ntau ntawm qhov hnyav ntawm qhov txav;

Nruab nrog high-precision puv-kaw-voj grating nplai;grating scale hom: Spain FAGOR los yog lub teb chaws Yelemees HEIDENHAIN;

Kev tiv thaiv kev tsheb ciav hlau: Cov ntaub thaiv npog tawv tawv yog siv rau kev tiv thaiv kom tsis txhob muaj cov khoom txawv teb chaws nkag mus thiab kis kab mob rau cov kev taw qhia rail.Cov ntaub thaiv npog muaj qhov zoo nkauj zoo nkauj thiab tsim nyog qauv.

CNC system maub los: Heidenhain TNC640

Hydraulic thiab Lubrication System

Lubrication system;lub tshuab no txais cov pab pawg ywj pheej roj muab tshuab

(1) Ib txheej ntawm kev ywj pheej tsis siv neeg cov roj thiab lubrication system tau txais kev pom zoo rau X, Y, Z axis qhia kev tsheb nqaj hlau, txhuas ntsia hlau thiab khib.Cov ntsia hlau bearing yog roj lubricated.Hom Lub Npe: Nanjing Bechier

Hydraulic system

(1) Lub tshuab no tau nruab nrog lub tshuab hydraulic ywj siab.

(2) Lub tshuab tau nruab nrog qhov chaw nres tsheb hydraulic sib cais, thiab lub tshuab hydraulic tau nruab nrog ntau yam kev saib xyuas kev nyab xeeb xws li lub tswb ntsuas roj, lub tswb ntsuas kub, lub tswb nrov nrov, thiab lub tswb ua haujlwm tsawg kawg nkaus kom ntseeg tau tias lub tshuab ua haujlwm nyob rau hauv ntau yam kev nyab xeeb., txhim kho kev tiv thaiv kev nyab xeeb ntawm cov neeg ua haujlwm.

(3) Hydraulic chaw nres tsheb hom: Dezhiyi Hydraulic

Tool magazine

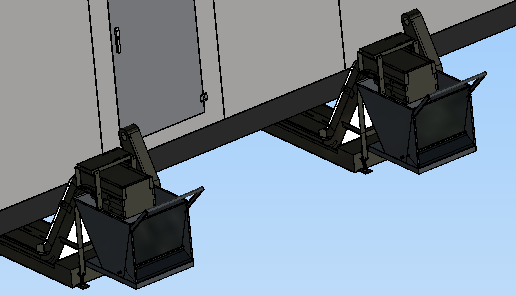

Kab rov tav cuab tam magazine-ob-txoj kev rau pem hauv ntej thiab thim rov qab arbitrary-32T cuab yeej magazine hom: Taiwan-nyiaj lag luam Desu/Okada los yog hom zoo sib xws

Chip conveyor

Chain phaj hom nti conveyors tau nruab rau ntawm ob sab ntawm lub rooj ua haujlwm, thiab cov pits tau nruab rau hauv lub hauv paus, uas muaj kev tiv thaiv kom zoo;

Cov nti conveyors ntawm ob sab ntawm qhov chaw ua haujlwm sai sai thauj cov hlau chips tsim los ntawm kev ua haujlwm siab mus rau kev nqa nti conveyor, txo cov thermal deformation thiab deformation ntawm lub tshuab, thiab xyuas kom meej thiab ruaj khov ntawm lub tshuab;

Cov ntaub ntawv technical

| Qauv | GMH-2245-Z |

| Lub rooj ua haujlwm loj (mm) | 2200 * 4000 hli |

| X-axis taug kev (mm) | 4 500 |

| Y-axis taug kev (mm) | 2500 |

| Z-axis taug kev (mm) | 1500 |

| Gantry dav (mm) | 3400 ib |

| Spindle kawg ntsej muag - ua hauj lwm lub rooj nrug (mm) | 150-1150 Nws |

| Spindle ceev (rpm) | 18 000 |

| Spindle tuav | HSK-A63 |

| C-axis kev sib hloov ntau yam (°) | ± 270 ° |

| A-axis kev sib hloov ntau yam (°) | ± 110 ° |

| Ua haujlwm load (t / m2) | 5 |

| kev ua haujlwm pub (m / min) | 20/20/20 |

| Ceev ceev (m / min) | 40/40/40 ib |

| Lub zog (kw) | 35 (S1) / 43.8 (S6 40%) |

| Torque (Nm) | 95 (S1) / 118 (S6 40%) |

| X / Y / Z qhov tseeb (mm) | 0.030/0.025/0.025 |

| A / C qhov tseeb (mm) | ± 5 |

| X / Y / Z repeatability (mm) | 0.015/0.010/0.010 |

| A/C Repeatability (mm) | ± 5 |

| Tool magazine | 32 |

| CNC system | HEIDENHAIN TNC 640 |

Standard configuration

| Siemens 840Dsl CNC system | Lub teb chaws Yelemees |

| X, Y, Z pub servo motors | HEIDENHAIN Lub teb chaws Yelemees |

| XYZ Servo Tsav | HEIDENHAIN Lub teb chaws Yelemees |

| AC Servo Spindle Tsav | HEIDENHAIN Lub teb chaws Yelemees |

| Tsib-axis tsib-txuas taub hau | Shanghai |

| Pob ntsia hlau | HIWIN los yog hom sib npaug |

| Linear Roller Guide | HIWIN los yog hom sib npaug |

| Txhua ncej ntsia hlau bearing | Nyiv NSK lossis hom sib npaug |

| Kev sib txuas | Taiwan los yog sib npaug hom |

| Kauv cutter | Shanghai |

| tshuab qhia rail tiv thaiv | Shanghai |

| Roj twj tso kua mis thiab centralized lubrication system | Proton los yog SKF los yog sib npaug |

| Qhov sib thooj hloov, nruab nrab relay | Omron / Schneider lossis sib npaug |

| tes mem tes generator | Cov neeg muab khoom siv tau tsim cov chaw tsim khoom / lossis hom sib npaug |

| Spindle | INNA los yog sib npaug |

| tshuab loj casting | Shanghai |

| tshuab ntawv hlau txheej tiv thaiv | Shanghai |

| tshuab thauj tog rau nkoj bolts, horn tiav teeb | Shanghai |

| Hydraulic system | nto moo nyob rau hauv Suav teb |

| Lub teeb ua haujlwm thiab teeb ceeb toom | nto moo nyob rau hauv Suav teb |

| Spindle ram balance mechanism | nto moo nyob rau hauv Suav teb |

| Spindle txias system thiab dej muab system | nto moo nyob rau hauv Suav teb |

| Cov cuab yeej tu vaj tse | nto moo nyob rau hauv Suav teb |

| Mechanical Instruction Manual |

|

| Phau ntawv qhia hluav taws xob |

|

| Daim ntawv pov thawj |

|

| Daim ntawv teev npe |

|

| Hluav taws xob schematic |

|

| Kev Tswj Xyuas Qhov System |

|

| Kev Tswj Xyuas Qhov System |

|

| System parameter phau ntawv |

|

| System Hoobkas parameter rooj |

|

| Lub hauv paus kev kos duab | Muab tom qab daim ntawv cog lus yuav siv tau |

| Control box kub regulator phau ntawv |

|

Ua tsaug rau koj mloog!