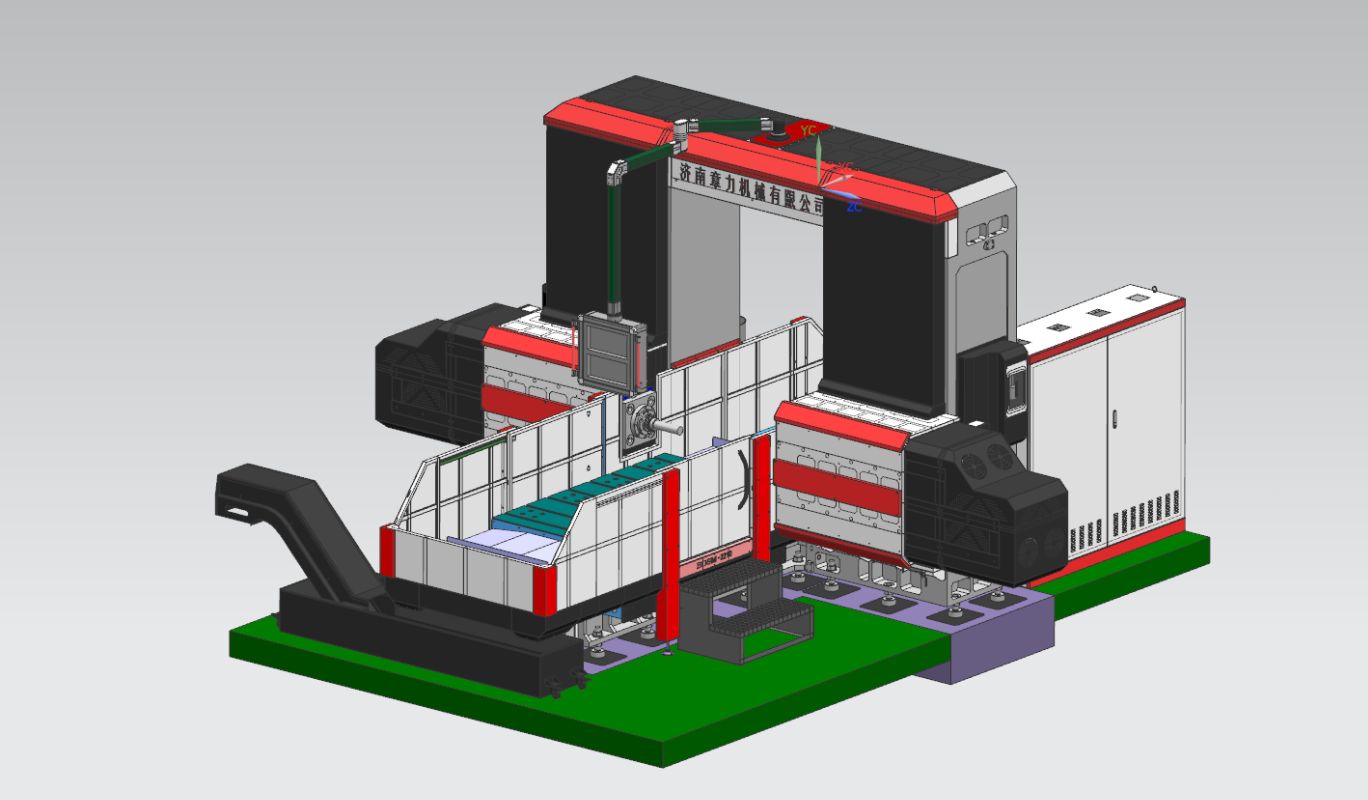

BOSM-5020-5Z Opsed-Head Boring Milling Tshuab

1.Khoom siv:

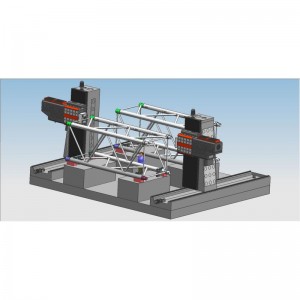

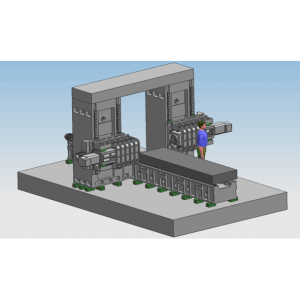

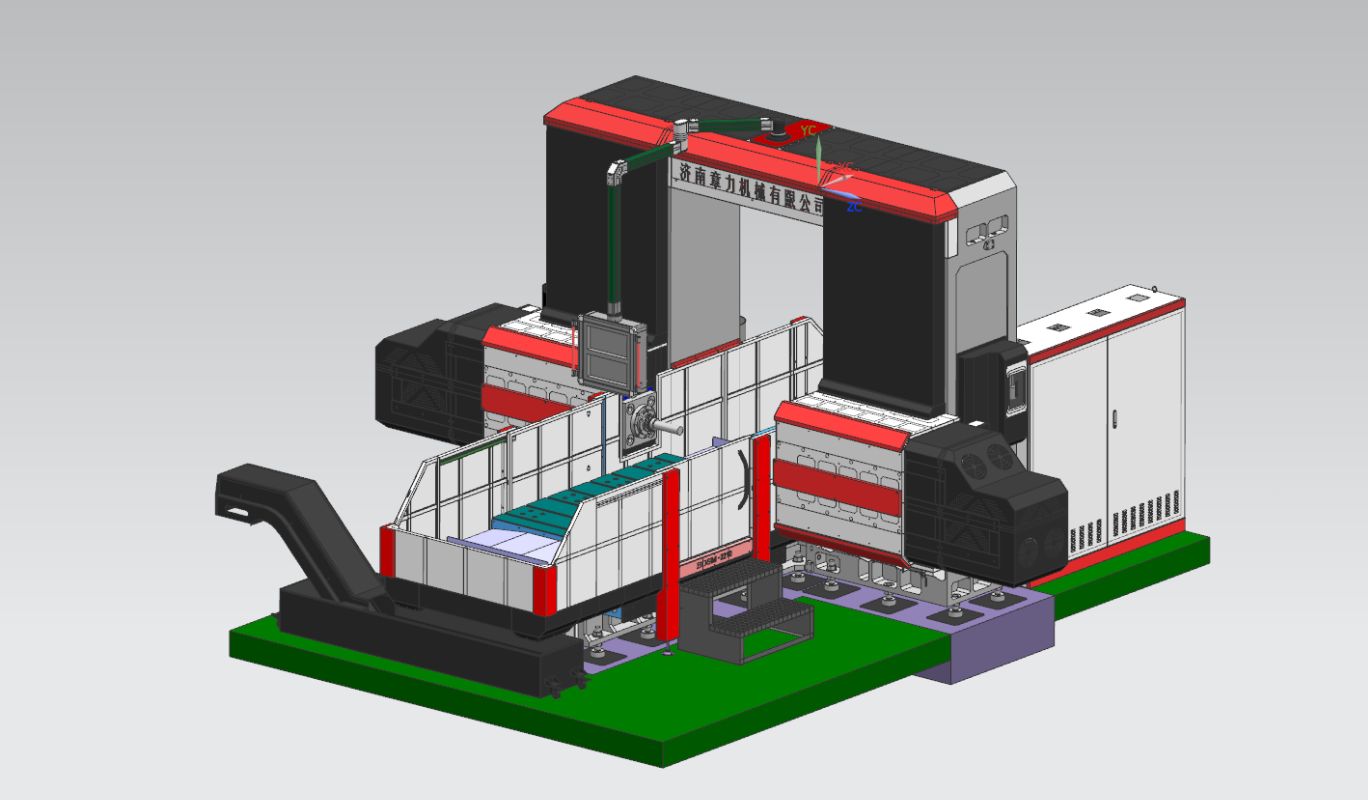

BOSM-5020-5Z CNC workbench mobile ob-kem taub hau-rau-lub taub hau tho txawv thiab milling tshuab yog ib lub tshuab tshwj xeeb rau engineering machinery symmetrical workpieces.Lub Tshuab yog nruab nrog ib tug tshwj xeeb movable workbench thiab ob txheej kab rov tav rams, uas muaj peev xwm paub txog Drilling, milling, tho txawv thiab lwm yam kev ua ntawm lub workpiece nyob rau hauv lub zoo stroke range, lub workpiece tuaj yeem ua tiav nyob rau hauv qhov chaw ib zaug (tsis xav tau. Secondary clamping), ceev ceev loading thiab unloading ceev, ceev positioning ceev, siab ua raug thiab siab ua efficiency.

2.Khoom siv:

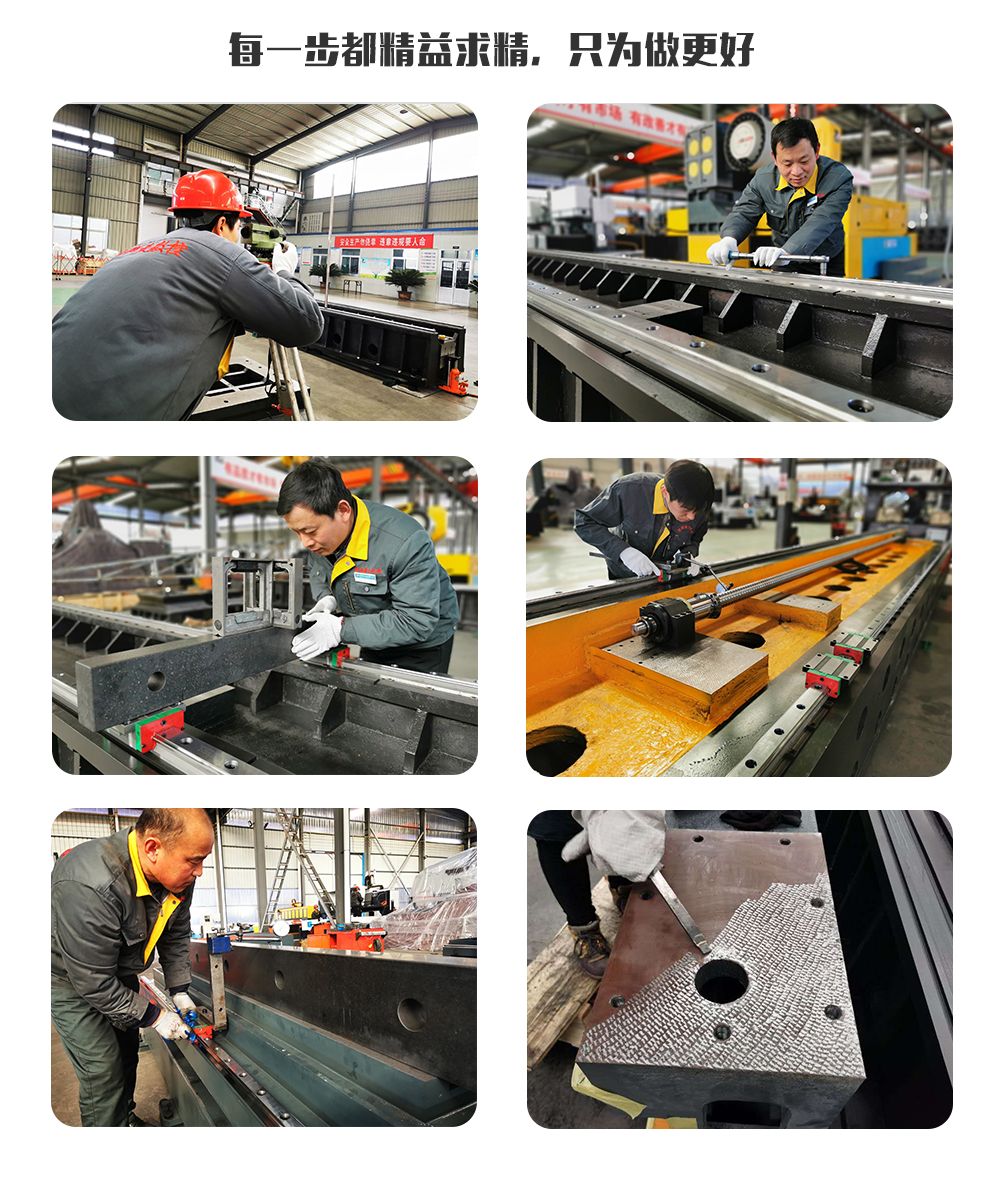

2.1. Cov khoom tseem ceeb ntawm lub tshuab

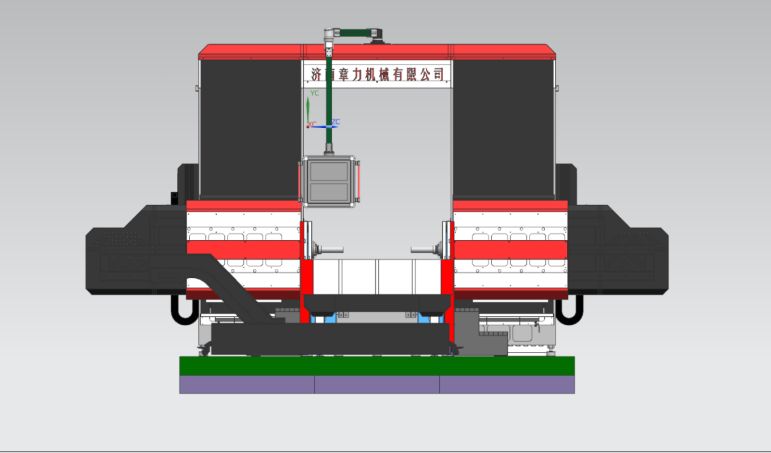

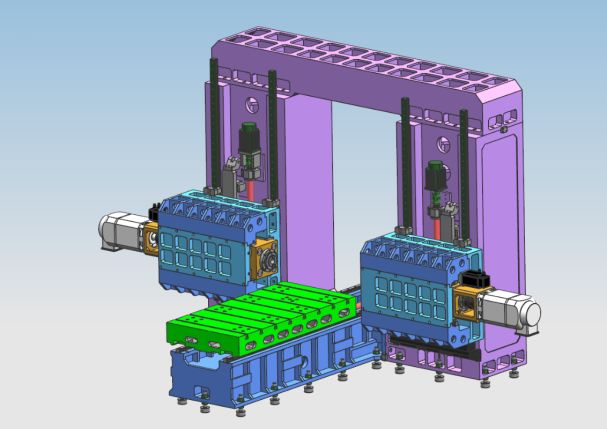

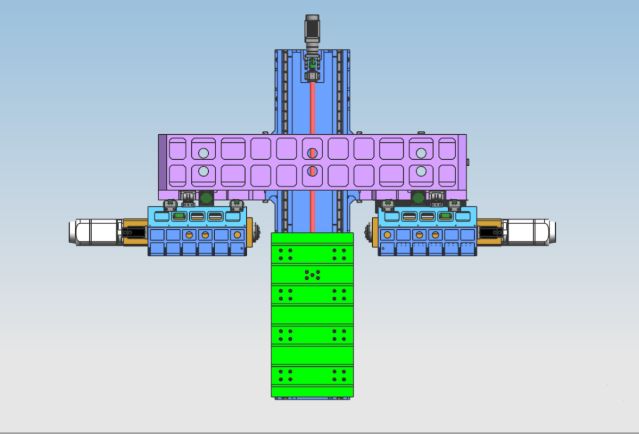

Lub txaj, workbench, sab laug thiab sab xis, kab teeb, gantry txuas kab teeb, eeb, rams, thiab lwm yam, yog txhua yam ua los ntawm resin xuab zeb molding, zoo grey hlau 250 casting, annealed hauv kub xuab zeb → kev co laus → cub annealing → kev co Aging → ntxhib machining → vibration aging → cub annealing → vibration aging → tiav, tshem tawm tag nrho cov kev ntxhov siab tsis zoo ntawm qhov chaw, thiab ua kom qhov kev ua tau zoo ntawm cov khoom ruaj khov.Lub txaj ruaj khov, sab laug thiab sab xis, lub gantry, thiab lub rooj zaum ua haujlwm;Lub Tshuab muaj milling, tho txawv txiav, drilling, countersinking, tapping thiab lwm yam dej num, lub cuab tam txias txoj kev yog sab nraud txias, lub tshuab muaj 5 axes pub, uas muaj peev xwm paub txog 4-axis linkage, 5-axis ib leeg-ua, 2 hwj chim taub hau , Lub Tshuab axial thiab Lub taub hau fais fab yog qhia hauv daim duab hauv qab no.

2.2. Lub ntsiab qauv ntawm axial kis tau tus mob pub ib feem

2.2.1.X-axis: Lub worktable reciprocates tom qab raws li cov lus qhia rail ntawm lub txaj ruaj.

X-axis kis tau tus mob: AC servo lub cev muaj zog thiab high-precision planetary reducer yog siv los tsav lub worktable los ntawm pob ntsia hlau xa mus kom paub X-axis linear tsab ntawv tsa suab.

Daim ntawv qhia kev tsheb nqaj hlau: nteg ob lub zog siab precision linear qhia kev tsheb nqaj hlau

2.2.2.Y1 axis: Lub hwj chim lub taub hau thiab ib tug ram yog vertically ntsia rau pem hauv ntej sab ntawm lub kem, thiab reciprocate sab laug thiab txoj cai raws li qhia rail ntawm lub kem.

Y1-axis kis tau tus mob: AC servo lub cev muaj zog yog siv los tsav lub pob ntsia hlau los tsav lub eeb kom txav mus, thiab paub txog Y1-axis linear suab.

Daim ntawv qhia kev tsheb nqaj hlau: 4 daim ntawm 45 hom kab qhia kev tsheb nqaj hlau.

2.2.3.Y2 axis: Qhov thib ob ram ntawm lub hwj chim lub taub hau yog ntsia vertically nyob rau hauv pem hauv ntej sab ntawm lub kem, thiab reciprocates sab laug thiab txoj cai raws li qhia rail ntawm lub kem.

Y2-axis kis tau tus mob: AC servo lub cev muaj zog yog siv los tsav lub pob ntsia hlau los tsav lub eeb txav kom paub txog cov kab tawm ntawm Y1-axis.

Daim ntawv qhia kev tsheb nqaj hlau: 4 daim ntawm 45 hom kab qhia kev tsheb nqaj hlau

2.2.4.Z1 axis: Lub hwj chim lub taub hau zawv zawg eeb tau teeb tsa ntsug ntawm sab xub ntiag ntawm sab xis, thiab rov ua dua thiab nqis raws kab lus qhia.

Z1-axis kis tau tus mob: AC servo lub cev muaj zog thiab high-precision planetary reducer yog siv los tsav lub ram txav los ntawm lub pob ntsia hlau kom paub Z1-axis linear suab.

Daim ntawv qhia kev tsheb ciav hlau: 2 65 hom kab qhia kev tsheb ciav hlau

2.2.5.Z2 axis: Lub hwj chim lub taub hau swb eeb yog ntsia vertically nyob rau sab pem hauv ntej ntawm sab xis, thiab reciprocates nce thiab nqis raws kab lus qhia rail.

Z1-axis kis tau tus mob: AC servo lub cev muaj zog ntxiv rau high-precision planetary reducer yog siv los tsav lub ram txav los ntawm lub pob ntsia hlau kom paub txog Z2-axis linear suab.

Daim ntawv qhia kev tsheb ciav hlau: 2 65 hom kab qhia kev tsheb ciav hlau

High quality HT250 casting kem 2 daim ntawm 65 hom hnyav-duty linear qhia rails

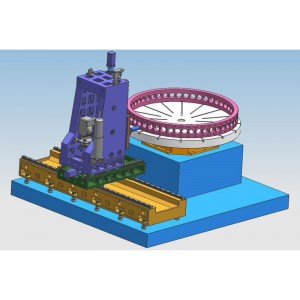

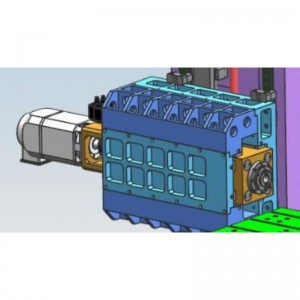

Lub tho txawv thiab milling lub zog lub taub hau (xws li lub taub hau lub hwj chim 1 thiab 2) yog ib qho square ram, thiab kev txav mus los yog coj los ntawm 4 txoj kab qhia cov menyuam.Tus tsav siv lub AC servo lub cev muaj zog tsav lub precision pob ntsia hlau khub.Lub tshuab yog nruab nrog ib tug nitrogen tshuav bar., Txo cov kabmob muaj peev xwm ntawm lub tshuab taub hau ntawm cov ntsia hlau thiab servo lub cev muaj zog.Z-axis lub cev muaj zog muaj qhov tsis siv neeg nres ua haujlwm.Nyob rau hauv qhov kev tshwm sim ntawm lub hwj chim tsis ua hauj lwm, lub tsis siv neeg nres yuav tuav lub cev muaj zog ncej kom nruj kom nws tsis tig.Thaum ua haujlwm, thaum lub laum me ntsis tsis kov lub workpiece, nws yuav pub sai heev;Thaum lub laum me ntsis kov lub workpiece, nws yuav cia li hloov mus ua hauj lwm pub.Thaum lub laum me ntsis nkag mus rau lub workpiece, nws yuav cia li hloov mus ceev rewind;Thaum kawg ntawm lub laum me ntsis tawm ntawm lub workpiece thiab mus txog qhov chaw teeb tsa, nws yuav txav mus rau qhov chaw tom ntej kom paub tias tsis siv neeg ncig.Thiab nws tuaj yeem paub txog kev ua haujlwm ntawm qhov muag tsis pom qhov drilling, milling, chamfering, nti tawg, tsis siv neeg nti tshem tawm, thiab lwm yam, uas txhim kho cov khoom tsim tau.

Lub 500mm stroke compound square ram hwj chim lub taub hau siv linear guides es tsis txhob ntawm cov tsoos inserts zoo heev txhim kho cov kev taw qhia raug thaum tuav lub rigidity ntawm lub square ram.

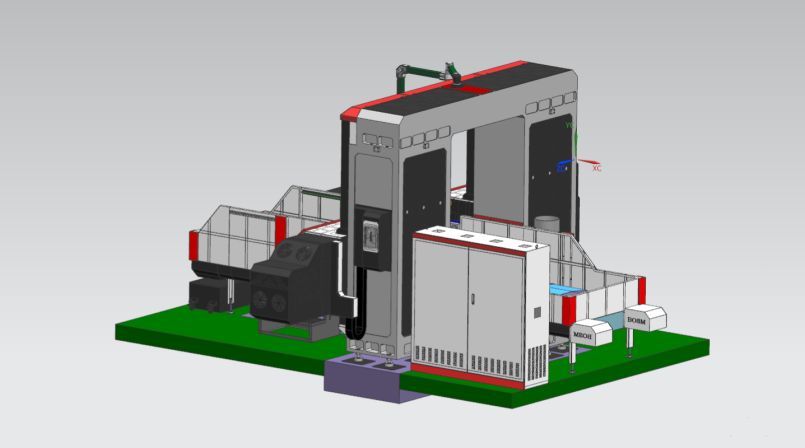

2.3. nti tshem tawm thiab txias

Muaj kauv thiab tiaj saw saw nti conveyors ntsia rau ntawm ob sab hauv qab ntawm lub workbench, thiab cov chips tuaj yeem raug xa mus rau cov nti conveyor thaum kawg los ntawm ob theem ntawm kauv thiab saw daim hlau kom paub txog kev tsim khoom.Muaj lub twj tso kua mis txias rau hauv lub tank coolant ntawm lub nti conveyor, uas tuaj yeem siv rau kev ua kom txias sab nraud ntawm lub cuab yeej los xyuas kom meej qhov kev ua haujlwm thiab kev pabcuam lub neej ntawm lub cuab yeej, thiab cov coolant tuaj yeem rov ua dua.

3.Full digital numerical control system:

3.1.Nrog nti tawg muaj nuj nqi, nti tawg lub sij hawm thiab nti tawg lub voj voog tuaj yeem teem rau ntawm tus txiv neej-tshuab interface.

3.2.Nruab nrog lub cuab yeej nqa kev ua haujlwm, lub cuab yeej nqa qhov deb tuaj yeem teeb tsa ntawm tus txiv neej-tshuab interface.Thaum qhov kev ncua deb mus txog, lub cuab yeej yog nqa tawm sai, ces cov chips raug pov tseg, thiab tom qab ntawd nws tau nrawm nrawm mus rau qhov chaw drilling thiab tau hloov mus ua haujlwm.

3.3.Centralized tswj lub thawv thiab chav tuav tes txais kev tswj cov lej thiab tau nruab nrog USB interface thiab LCD kua siv lead ua zaub.Txhawm rau ua kom yooj yim programming, cia, tso saib thiab kev sib txuas lus, kev ua haujlwm interface muaj cov haujlwm xws li kev sib tham ntawm tus txiv neej-tshuab, kev ua yuam kev yuam kev, thiab lub tswb tsis siv neeg.

3.4.Cov cuab yeej muaj kev ua haujlwm ntawm kev saib ua ntej thiab rov tshuaj xyuas qhov chaw ua ntej ua haujlwm, thiab kev ua haujlwm yooj yim heev.

4.Tsis siv neeg lubrication

Tshuab precision linear qhia rail khub, precision pob ntsia hlau khub thiab lwm yam high-precision motion khub yog nruab nrog tsis siv neeg lubrication tshuab.Lub twj tso kua mis tsis siv neeg lubricating tso tawm cov roj siab, thiab cov roj lubricator roj chamber nkag mus rau cov roj.Tom qab cov roj chamber tau ntim cov roj, thaum lub kaw lus siab nce mus rau 1.4-1.75Mpa, lub siab hloov hauv lub kaw lus kaw, lub twj tso kua mis nres, thiab lub valve unloading unloads tib lub sijhawm.Thaum cov roj siab nyob rau hauv txoj kev poob qis dua 0.2Mpa, lub lubricator kom muaj nuj nqis pib sau lub lubricating point thiab ua tiav ib qho roj filling.Vim muaj cov roj zoo ntawm cov roj injector kom muaj nuj nqis thiab nrhiav kom tau lub zog siab, cov khoom siv roj yog txhim khu kev qha, kom ntseeg tau tias muaj cov roj zaj duab xis nyob rau saum npoo ntawm txhua khub kinematic, txo kev sib txhuam thiab hnav, thiab tiv thaiv kev puas tsuaj rau. cov qauv sab hauv tshwm sim los ntawm overheating., los xyuas kom meej qhov tseeb thiab lub neej ntawm Lub Tshuab.Piv nrog rau cov zawv zawg phau ntawv qhia kev tsheb nqaj hlau, cov dov kab qhia kev tsheb ciav hlau siv hauv lub tshuab no muaj cov txiaj ntsig zoo:

① Lub zog rhiab heev, kev sib txhuam coefficient ntawm dov qhia kev tsheb nqaj hlau me me, tsuas yog 0.0025 ~ 0.01, thiab lub zog tsav tsheb tau txo qis heev, uas tsuas yog sib npaug rau 1/10 ntawm cov tshuab zoo tib yam.

② Qhov sib txawv ntawm kev sib txhuam thiab zoo li qub yog qhov me me, thiab qhov kev ua tau zoo tom qab yog qhov zoo heev, uas yog, lub sijhawm luv ntawm lub teeb liab tsav tsheb thiab cov tshuab ua haujlwm yog luv heev, uas yog qhov tsim nyog rau kev txhim kho cov lus teb ceev thiab rhiab heev ntawm tus lej tswj qhov system.

③Nws yog tsim rau high-speed linear motion, thiab nws instantaneous ceev yog hais txog 10 lub sij hawm siab tshaj ntawm zawv zawg qhia rails.

④ Nws tuaj yeem paub qhov txawv txav tsis zoo thiab txhim kho kev txav rigidity ntawm lub tshuab tshuab.

⑤ Tsim los ntawm cov kws tshaj lij cov tuam txhab, nws muaj qhov siab precision, zoo versatility thiab yooj yim txij nkawm.

5.Peb-axis laser soj ntsuam:

Txhua lub tshuab ntawm Bosman yog ntsuas los ntawm lub laser interferometer ntawm RENISHAW lub tuam txhab nyob rau hauv lub tebchaws United Kingdom kom raug kuaj xyuas thiab them nyiaj rau lub suab yuam kev, backlash, positioning raug, rov positioning raug, thiab lwm yam. tshuab.Kev tshuaj xyuas Ballbar Txhua lub tshuab siv lub ballbar los ntawm British RENISHAW lub tuam txhab los ntsuas qhov tseeb lub voj voog raug thiab tshuab geometric raug, thiab ua cov kev sim txiav ncig tib lub sijhawm los xyuas kom meej 3D machining raug thiab ncig qhov tseeb ntawm lub tshuab.

6.Machine siv ib puag ncig:

6.1.Cov khoom siv siv ib puag ncig cov cai

Kev tswj hwm qhov ntsuas kub tsis tu ncua yog qhov tseem ceeb rau kev ua haujlwm precision.

(1) Muaj qhov xav tau ntawm qhov kub thiab txias yog -10 ° C txog 35 ° C, thaum qhov kub thiab txias yog 20 ° C, cov av noo yuav tsum yog 40% txog 75%.

(2) Txhawm rau kom qhov tseeb zoo li qub ntawm Lub Tshuab nyob rau hauv qhov kev teev tseg, qhov zoo tshaj plaws ambient kub yuav tsum yog 15 ° C txog 25 ° C, thiab qhov kub sib txawv yuav tsum tsis pub tshaj ± 2 ° C / 24h.

6.2.Fais fab mov voltage: 3 theem, 380V, nyob rau hauv qhov ntau ntawm ± 10% voltage fluctuation, fais fab mov zaus: 50HZ.

6.3.Yog tias qhov hluav taws xob nyob rau hauv cheeb tsam ntawm kev siv tsis ruaj khov, Lub Tshuab yuav tsum tau nruab nrog lub zog ruaj khov kom ntseeg tau tias lub tshuab ua haujlwm li qub.

6.4.Lub tshuab yuav tsum muaj kev txhim khu kev qha hauv av: cov xaim hauv av yog cov hlau tooj liab, txoj kab uas hla ntawm cov hlau yuav tsum tsis pub tsawg dua 10mm², thiab cov av tiv thaiv yuav tsum tsawg dua 4 ohms.

6.5.Txhawm rau kom ntseeg tau tias kev ua haujlwm zoo ntawm cov cuab yeej siv, yog tias cov cua compressed ntawm cov cua tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm cov khoom siv cua, cov khoom siv cua lim cua (dehumidification, degreasing, filtering) yuav tsum tau ntxiv ua ntej cua nkag. ntawm lub tshuab.

6.6.Khaws cov khoom kom deb ntawm lub hnub ci ncaj qha, kev co thiab qhov chaw tshav kub, lub tshuab hluav taws xob ntau zaus, lub tshuab hluav taws xob vuam, thiab lwm yam, kom tsis txhob muaj tshuab ntau lawm lossis poob ntawm lub tshuab raug.

7.Technical tsis:

| Qauv | 5020-5 ZPO | |

| Kev ua haujlwm siab tshaj plaws workpiece loj | Length × dav × qhov siab (mm) | 5000 × 2000 × 2500 hli |

| Gantry siab tshaj pub | Dav (mm) | 2300 |

| ua hauj lwm rooj loj | Length X Dav (mm) | 5000 * 2000 hli |

| Rooj mus ncig | Workbench txav rov qab thiab tawm mus (mm) | 5000 |

| Ob chav ram nqa nce thiab nqis | Up thiab down stroke ntawm ram (mm) | 2500 |

| Kab rov tav ram hom drilling taub hau hwj chim taub hau ib ob | Quantity (2) | 2 |

| Kab rov tav ram hom drilling taub hau hwj chim taub hau ib ob | Spindle taper | BT50 |

| Spindle ceev (r / min) | 30-5000 | |

| Servo spindle lub cev muaj zog (kw) | 37 * 2 | |

| Qhov kev ncua deb ntawm qhov chaw ntawm lub qhov ntswg kawg ntawm ob lub spindles (mm) | 1500-2500 hli | |

| Sab laug thiab sab xis ntawm ib leeg ram (mm) | 500 | |

| Sab laug thiab txoj cai stroke ntawm ob ram (mm) | 1000 | |

| Bidirectional Positioning raug | 300mm * 300 hli | ± 0.025 |

| Bi-directional rov positioning raug | 300mm * 300 hli | ± 0.02 hli |

| Qhov hnyav tag nrho (t) | (txog) 55 | Qhov hnyav tag nrho (t) |