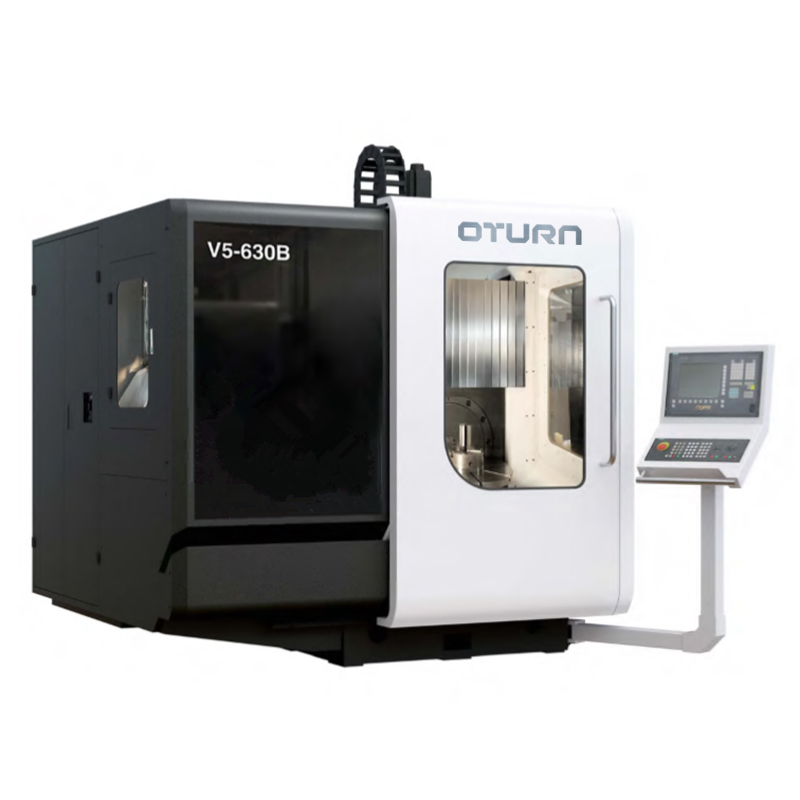

5-Axis Vertical Machining Center Nrog Txoj Kev Ua Haujlwm

Tsib-Axis Vertical Machining Center

Lub V5-630B tsib-axis machining chaw txais yuav ib tug ruaj khov C-zoo li tus qauv, kem yog tsau nyob rau hauv lub txaj, lub slider phaj txav tom qab ntawm kem (X kev taw qhia), lub rooj zaum swb txav longitudinally (Y kev taw qhia), thiab cov headstock txav vertically raws lub rooj zaum swb (Z kev taw qhia). Lub worktable txais tus kheej-tsim direct-tsav ib leeg-arm cradle qauv, thiab ntau yam kev ua tau zoo qhia tau mus txog lub thoob ntiaj teb advanced theem.

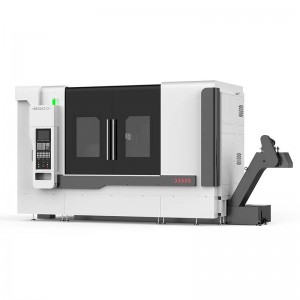

CNC maub los: Siemens 840D

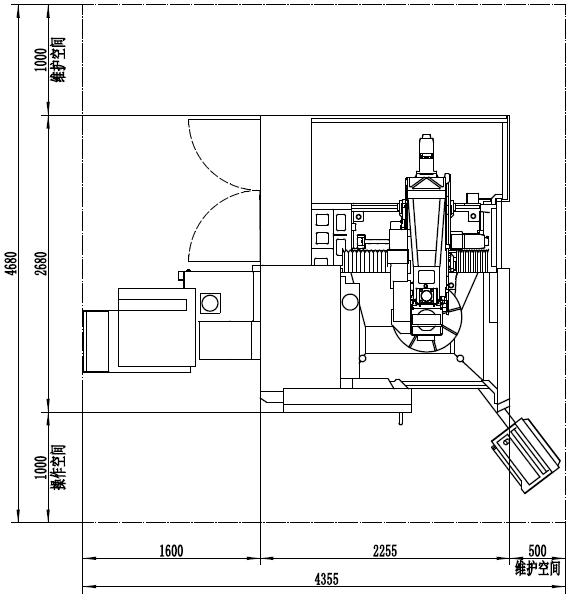

Tshuab qauv layout:

Pub noj system

X, Y, Z axes txais yuav ultra-high rigidity, high-precision roller linear guides thiab high-performance pob screws, nrog tsis tshua muaj dynamic thiab zoo li qub kev sib txhuam, siab rhiab heev, tsis tshua muaj kev vibration, tsis tshua muaj creep-dawb, siab. qhov chaw raug, thiab zoo heev servo tsav kev ua tau zoo.

X, Y, Z axis servo motors ncaj qha txuas nrog high-precision pob screws los ntawm cov couplings, txo cov kev sib txuas nruab nrab, paub qhov sib txawv tsis pub kis, yoo mov yooj yim, qhov tseeb, thiab kev sib kis siab.

Z-axis servo lub cev muaj zog muaj lub zog nres. Nyob rau hauv cov ntaub ntawv ntawm lub hwj chim tsis ua hauj lwm, nws muaj peev xwm cia li tuav lub nres los tuav lub cev muaj zog ncej kom nruj kom nws tsis tig, uas plays lub luag hauj lwm nyob rau hauv kev ruaj ntseg kev tiv thaiv.

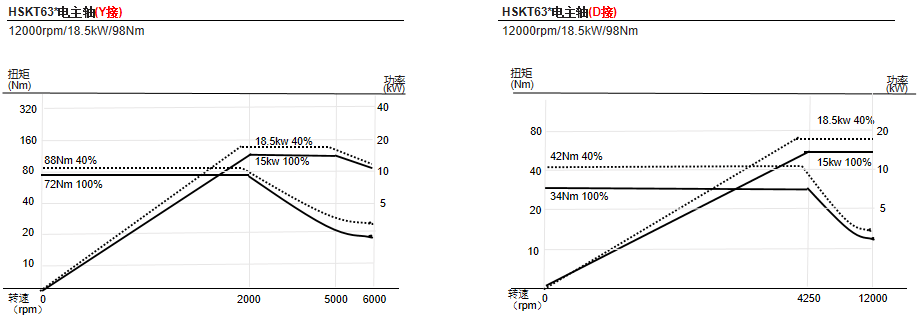

Hluav taws xob spindle

Lub motorized spindle txais yuav tus kheej-tsim HSKT63 motorized spindle nrog built-in kawg hniav phaj, uas muaj peev xwm paub lub compound muaj nuj nqi ntawm tig thiab milling. Qhov kawg yog nruab nrog lub nplhaib txau sib koom ua kom txias lub cuab yeej. Stepless ceev tswj, built-in high-precision encoder, tuaj yeem ua tiav cov lus qhia raug nres thiab nruj tapping.

Lub rooj

Tus kheej-tsim ncaj-tsav cradle turntable yog nruab nrog ib tug high-precision absolute encoder thiab yog txias los ntawm ib tug dej txias ntawm qhov kub thiab txias. Nws muaj qhov zoo ntawm siab rigidity, siab precision, thiab siab dynamic teb. Lub rooj ua haujlwm tau txais 8-14mm radial T-slots, qhov siab tshaj plaws load yog 500kg (kab rov tav), 300kg ( ntsug), thiab qhov siab tshaj plaws workpiece txoj kab uas hla yog¢650.

Tool magazine

Cov cuab yeej magazine txais HSKA63 manipulator disc hom cuab yeej magazine, uas tuaj yeem ua tau 24cuab yeej.

Tag nrho kaw lub voj tawm tswv yim system

X, Y, Z linear axes yog nruab nrog Renishaw tus nqi grating scale; B thiab C cov lus teb tau nruab nrog HEIDENHAIN RCN2000 series tus nqi ntawm lub kaum sab xis encoders kom paub tag nrho kaw-loop tawm tswv yim ntawm 5 pub axes,guarante siab precision thiab siab precision tuav.

Cua txias thiab pneumatic system

Nruab nrog loj txaus txias twj tso kua mis thiab lub tank dej kom txaus txias rau cov cuab yeej thiab workpieces. Lub taub hau kawg lub ntsej muag yog nruab nrog lub tshuab cua txias, uas yog tswj los ntawm M code lossis tswj vaj huam sib luag.

Nruab nrog lub tshuab dej txias rau qhov txias txias, kom ntseeg tau tias lub tshuab hluav taws xob thiab lub tshuab hluav taws xob ncaj qha tau ua haujlwm zoo thiab tuaj yeem ua haujlwm tau ntev.

Lub tshuab pneumatic siv cov khoom siv pneumatic los lim, thiab paub txog kev ua haujlwm ntawm kev tu thiab tshuab lub taper qhov ntawm spindle, huab cua-sealing tiv thaiv ntawm spindle bearing, tig dua lub cuab tam tuav ntawm lub cuab yeej magazine, thiab tshuab lub grating kav.

Centralized lubrication system

Lub swb thaiv ntawm cov lus qhia kev tsheb nqaj hlau thiab cov txiv ntoo ntawm lub pob ntsia hlau yog txhua yam lubricated nrog cov roj nyias, thiab cov roj lubrication tau muab tsis tu ncua thiab ntau kom ntseeg tau tias qhov tseeb thiab ruaj khov ntawm lub pob ntsia hlau thiab cov lus qhia kev tsheb nqaj hlau.

Roj-cua lubrication system

Lub tshuab hluav taws xob ntxaiv yog nruab nrog cov roj thiab roj lubricating, uas tuaj yeem ua tiav lubricate thiab txias ntxaiv. Lub sensor tuaj yeem muab lub tswb ceeb toom tsis zoo, uas tuaj yeem ua kom ntseeg tau tias cov ntxaiv tuaj yeem ua haujlwm ruaj khov ntawm kev kub ceev rau lub sijhawm ntev.

Workpiece ntsuas qhov system

Covtshuabyog nruab nrog Renishaw OMP40 optical sojntsuam, siv ua ke nrog OMI-2 receiver, uas muaj zog tiv thaiv lub teeb cuam tshuam, tsis muaj tseeb triggering thiab cuam tshuam, thiab kev ntsuas ib-txoj kev repeatability tsawg dua los yog sib npaug rau 1um (480mm / min ntsuas. ceev, siv 50mm ntsuas koob), qhov kev khiav hauj lwm kub yog 5 ° C txog 55 ° C.

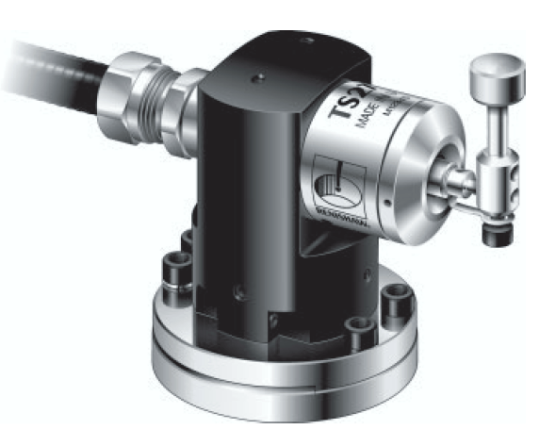

Cov cuab yeej ntsuas qhov system

Lub tshuab yog nruab nrog Renishaw's TS27R cov cuab yeej ntsuas qhov system, uas ua rau kev tshawb pom kev tawg ntawm ntau yam cuab yeej thiab ntsuas nrawm ntawm cov cuab yeej ntev thiab txoj kab uas hla.

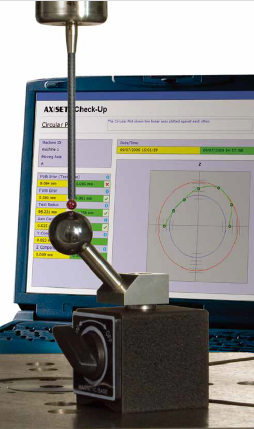

Tsib-axis precision calibration muaj nuj nqi

Lub tshuab yog nruab nrog Renishaw's AxiSet Check-Up Rotary Axis Line Checker cov khoom, ua ke nrog OMP40 workpiece ntsuas qhov system, ua rautshuabcov neeg siv kom sai thiab raug txheeb xyuas qhov xwm txheej ntawm cov axis teb thiab txheeb xyuas cov teeb meem tshwm sim los ntawm kev hloov pauv ntawm qhov kub thiab txias,tshuabKev sib tsoo lossis teeb meem hnav thiab tsim kua muag, tuaj yeem kho sai sai thiab nrhiav kev kuaj xyuas kev ua tau zoo, ntsuas ntsuas thiab saib xyuas qhov nyuaj npaum li castshuabs hloov raws sijhawm.

Kev tiv thaiv tshuab

Lub tshuab txais ib qho kev tiv thaiv npog uas ua tau raws li cov qauv kev nyab xeeb los tiv thaiv kev sib tsoo ntawm cov coolant thiab chips, ua kom muaj kev nyab xeeb thiab zoo nkauj zoo nkauj. Lub X-kev taw qhia ntawm lub tshuab yog nruab nrog ib tug armored tiv thaiv npog, uas muaj peev xwm tiv thaiv cov kev taw qhia rail thiab pob ntsia hlau.

Tshuab tej yam kev mob

(1) Fais fab mov: 380V±10% 50HZ±1HZ peb-theem alternating tam sim no

(2) Ambient kub: 5℃-40℃

(3) Qhov kub thiab txias: 22℃ ±2℃

(4) txheeb ze humidity: 20-75%

(5) Cua qhov chaw siab: 6±1 bar

(6) Huab cua ntws: 500L / min

Main Specification

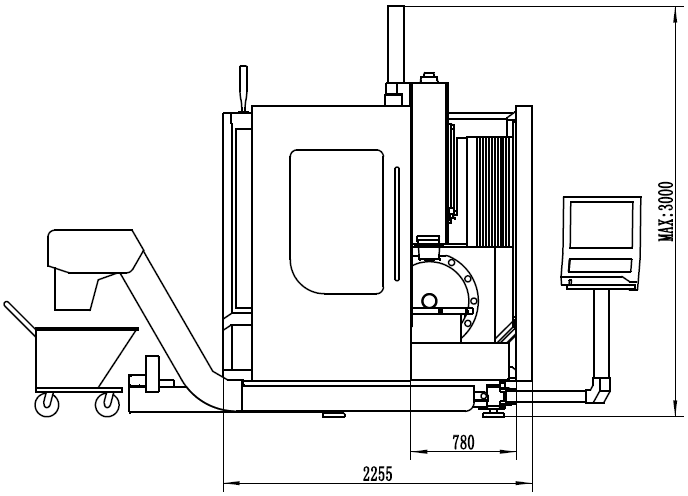

| Yam khoom | Chav tsev | Specification | |

| Lub rooj ua haujlwm | Worktable txoj kab uas hla | mm | ib 630 |

| Maximum kab rov tav load | kg | 500 | |

| Max ntsug load | kg | 300 | |

| T-qhov | mm | 8 x14 | |

| Kev ua haujlwm ntau | Kev ncua deb ntawm spindle kawg lub ntsej muag thiab worktable kawg lub ntsej muag(Max) | mm | 550 |

| Kev ncua deb ntawm spindle kawg lub ntsej muag thiab worktable kawg lub ntsej muag(Min) | mm | 150 | |

| X axis | mm | 600 | |

| Y axis | mm | 450 | |

| Z axis | mm | 400 | |

| B axis | ° | -35 ° ~ + 110 ° | |

| C axis | ° | 360 ° | |

| Spindle | Lub khob hliav qab | CTB | TIAB SA 63 |

| Rated ceev | rpm ua | 2000 | |

| Qhov ceev tshaj plaws | Nm | 12000 | |

| Cov zis torque S1 / S6 | Nm | 72/88 ib | |

| Spindle lub cev muaj zog S1 / S6 | kW | 15/18.5 Nws | |

| Axis | X axis ceev traverse ceev | m/min | 36 |

| Y axis ceev traverse ceev | m/min | 36 | |

| Z axissKev nrawm nrawm nrawm | m/min | 36 | |

| B axis Max.ceev | rpm ua | 80 | |

| C axissMax.ceev | rpm ua | 800 | |

|

| X / Y / Z axis lub cev muaj zog | KW | 2.2 |

|

| B / C axis Lub cev muaj zog | KW | 13.3/30 Nws |

|

| B-axis Rated torque | Nm | 2540 ib |

|

| C-Axis Rated torque | Nm | 400 |

| Tool magazine | Hom |

| Hom Disc |

| Txoj kev xaiv cuab yeej |

| Bidirectional ze tshaj plaws xaiv cov cuab yeej | |

| Muaj peev xwm | T | 24 | |

| Max.cuab tam ntev | mm | 300 | |

| Max.twj luj | kg | 8 | |

| Max.cutter disc txoj kab uas hla(puv Tool) | mm | ib φ80 | |

| Qhov siab tshaj plaws cutter disc txoj kab uas hla (Cov cuab yeej uas nyob ib sab) | mm | φ150 | |

| Qhov tseeb | Kev cai lij choj |

| GB / T20957.4 (ISO 10791-4) |

| Positioning raug (X / Y / Z) | mm | 0.008 ib | |

| positioning raug (B/C) |

| 6"/6" | |

| Rov ua dua qhov tseeb (X / Y / Z) | mm | 0.006 ib | |

|

| Rov ua dua qhov tseeb (B/C) |

| 4"/4" |

| Qhov hnyav | kg | 6500 | |

| Muaj peev xwm | KVA | 45 | |

| Tshuab loj | mm | 4 350×4000×3000 | |

Txheem configurations

| 1. Cov khoom tseem ceeb (xws li txaj, kem, zawv zawg phaj, zawv zawg rooj, ntxaiv lub thawv) |

| 2. X, Y, Z peb-axis pub system |

| 3. Ib leeg-arm cradle-type turntable BC630-4400T-42540T-800/800-50/80-RCNS |

| 4. Fais spindle HSKT63 |

| 5. Hluav taws xob tswj qhov system (xws li hluav taws xob txee, fais fab module, servo module, PLC, ua haujlwm vaj huam sib luag, zaub, chav tuav tes, hluav taws xob txee cua txias, thiab lwm yam.) |

| 6. Hydraulic system |

| 7. Pneumatic system |

| 8. Centralized lubrication system |

| 9. Roj-cua lubrication system |

| 10. Dej txias |

| 11. Chip conveyor, dej tank, chip collector |

| 12. Grating kav |

| 13. Rail guard |

| 14. tshuab zuag qhia tag nrho kev tiv thaiv npog |

| 15. Workpiece ntsuas qhov system |

| 16. Cov cuab yeej teeb tsa |

| 17. Tsib-axis precision calibration muaj nuj nqi |

| Tshuab cov ntaub ntawv daim ntawv pov thawj Cov ntawv ntim khoom 1 txheej tshuab phau ntawv (electronic version) tshuab thaub qab cov ntaub ntawv 1 teeb (U disk) 840D alarm diagnostic phau ntawv 1 teeb (electronic version) 840D Milling Operation Manual 1 (Electronic Version) 840D programming phau ntawv yooj yim ntu 1 (electronic version)) |

Main Configurations

| Lub npe | Hom | Lus ceeb toom |

| X / Y / Z axis lub cev muaj zog thiab tsav | Siemens |

|

| Lub zog saw | ua igus |

|

| Ntsia hlau bearing | NSK/NWS |

|

| Cov Lus Qhia Linear | THK |

|

| Tool magazine | Okada |

|

| Centralized lubrication | hav |

|

| Pob ntsia hlau | THK |

|

| Pneumatic Cheebtsam | SMC |

|

| Electric txee cua txias | ya ua ke |

|

| dej txias | ya ua ke |

|

| grating kav | Renishaw |

|

| Workpiece ntsuas qhov system | Renishaw |

|

| Cov cuab yeej ntsuas qhov system | Renishaw |

|

Standard Accessories

| Accessory npe | Specification | Ntau |

| Tshuab txaj hlau |

| 4set ib |

| nplhaib | M20 | 2 qab |

| nplhaib | M30 | 2 qab |

| tshem tawm | 5T×2,85m ua | 1 |

| tshem tawm | 5T×2,8m ua | 1 |

| tshem tawm | 5T×3,75m ua | 1 |

| tshem tawm | 5T×3,8m ua | 1 |

| Torx qhib-kawg wrench | 22 | 1 |

| Allen tus yuam sij | 10 | 1 |

| Allen tus yuam sij | 12 | 1 |

| T-nuj | M12 | 4 |

| Spindle tuav |

| 1 |

| X-axis mount |

| 1 |

| Y-axis kho |

| 1 |

Ua tsaug rau koj mloog!