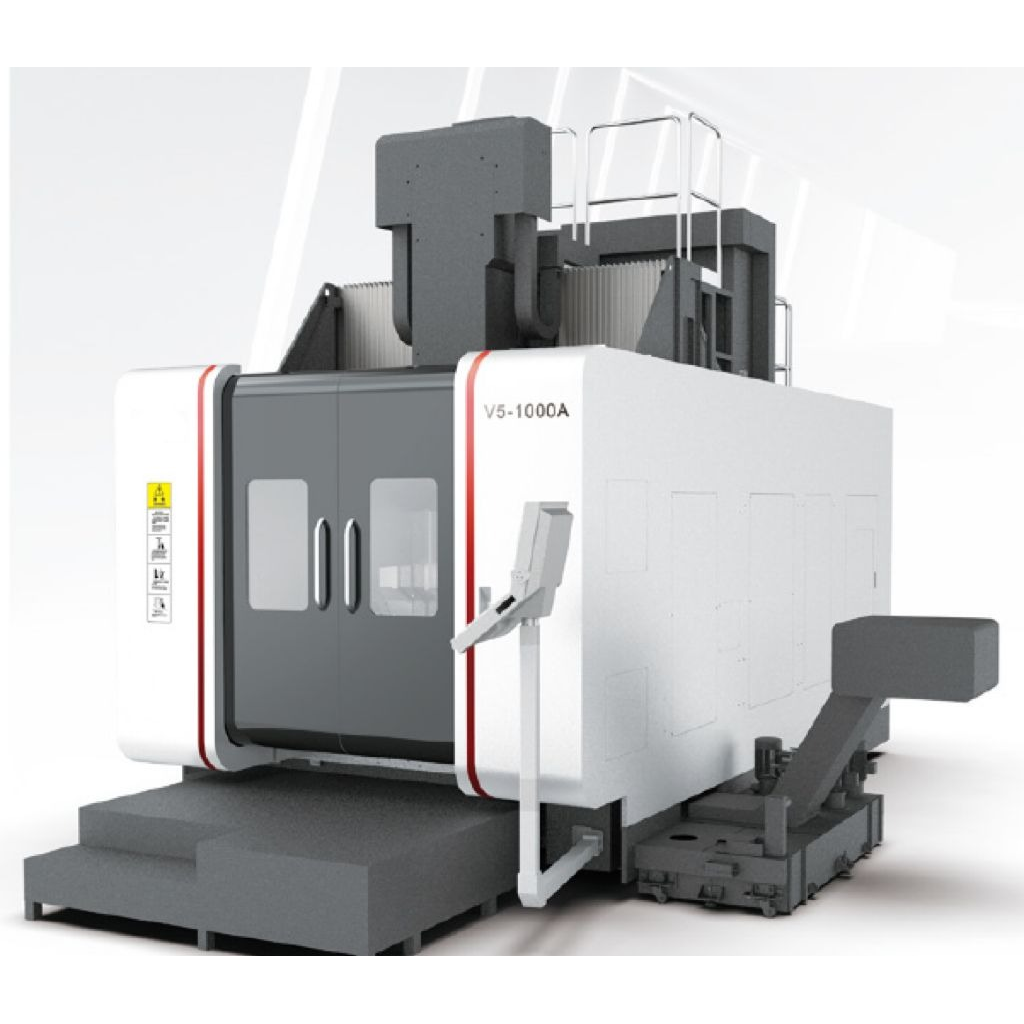

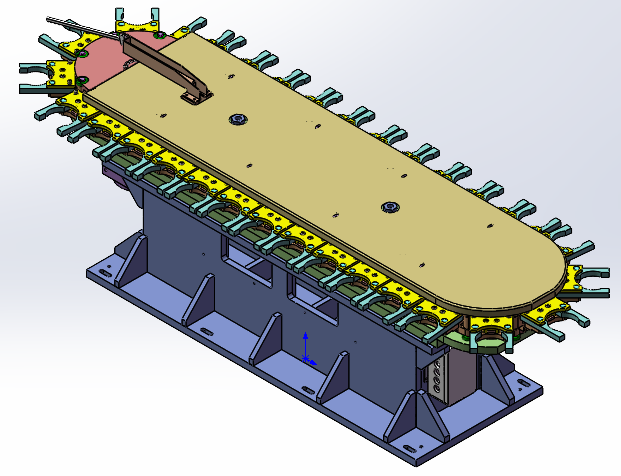

V5-1000A 5-axis machining chaw

Tsib-Axis Vertical Machining Center

Lub V5-1000A tsib-axis machining chaw txais yuav ib tug ruaj khov kaw gantry qauv thiab yog nruab nrog ib tug qauv hluav taws xob spindle, ib tug ob-axis ncaj-tsav CNC turntable thiab kab rov tav saw servo cuab yeej magazine. Nws tuaj yeem paub qhov kev kub ceev, siab-precision, thiab ua haujlwm zoo ntawm qhov nyuaj. Nws yog dav siv nyob rau hauv tshiab Manufacturing ntawm lub zog tsheb, aviation ib blisks, chav turbine impellers, pwm thiab lwm yam khoom.

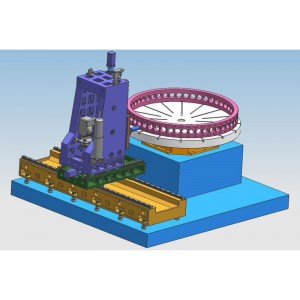

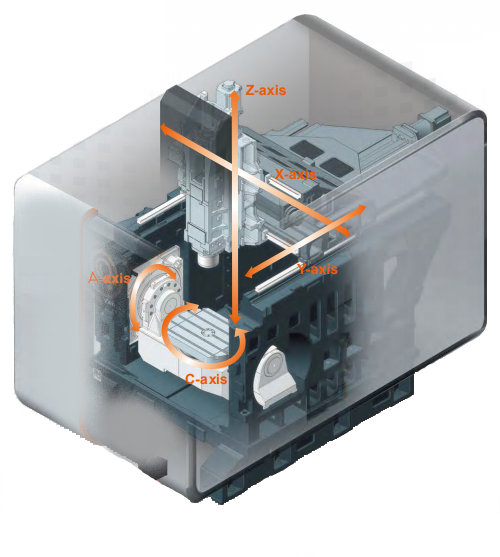

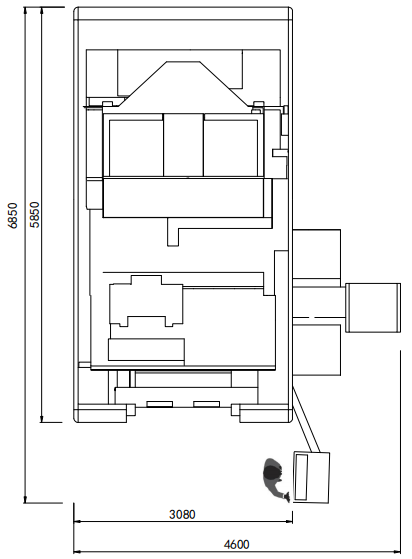

1. Tag nrho cov txheej txheem ntawm lub tshuab

Lub V5-1000A tsib-axis machining chaw txais kev ruaj ntseg gantry qauv, kem yog tsau rau ntawm lub hauv paus, lub nqaj txav longitudinally raws kab (Y kev taw qhia), lub phaj swb txav tom qab raws kab (X kev taw qhia), thiab headstock txav vertically raws tus swb phaj (Z kev taw qhia). Lub workbench txais tus kheej-tsim ncaj-tsav cradle qauv, thiab ntau yam kev ua tau zoo tau mus txog qib siab thoob ntiaj teb.

2. Kev noj zaub mov

Lub X, Y, Z axes txais yuav ultra-high rigidity, high-precision cov menyuam kab qhia thiab cov khoom ua haujlwm siab, nrog kev sib txhuam tsis tshua muaj zog thiab zoo li qub, siab rhiab heev, tsis tshua muaj kev vibration ntawm kev kub ceev, tsis muaj creep ntawm qis ceev, siab positioning. raug, thiab zoo heev servo tsav kev ua tau zoo.

X, Y, Z axis servo motors txuas nrog lub siab precision pob screws los ntawm precision reducers, nrog saj zawg zog noj, raug qhov chaw thiab siab kis precision.

Z-axis servo lub cev muaj zog muaj lub zog nres. Nyob rau hauv cov ntaub ntawv ntawm lub hwj chim tsis ua hauj lwm, nws muaj peev xwm cia li tuav lub nres los tuav lub cev muaj zog ncej kom nruj kom nws tsis tig, uas plays lub luag hauj lwm nyob rau hauv kev ruaj ntseg kev tiv thaiv.

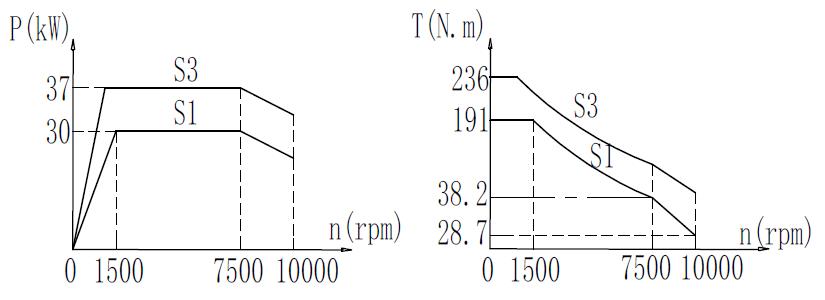

3. Hluav taws xob spindle

Lub motorized spindle txais yuav tus kheej-tsim BT50 motorized spindle (HSKA100 motorized spindle yog xaiv tau), thiab qhov kawg yog nruab nrog ib lub nplhaib txau sib koom ua kom txias lub cuab yeej. Nws muaj qhov zoo ntawm kev kub ceev, siab precision, siab dynamic teb, thiab lwm yam, thiab muaj peev xwm paub stepless ceev kev tswj, built-in high-precision encoder, muaj peev xwm ua tiav cov lus qhia raug nres thiab nruj tapping.

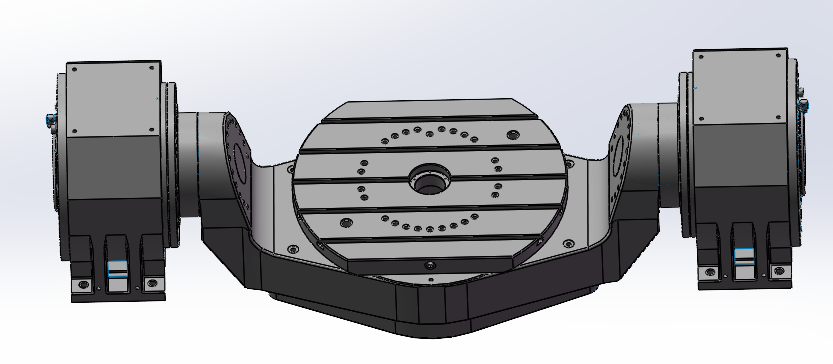

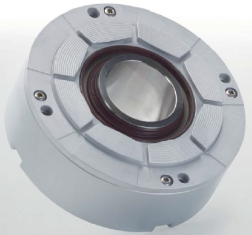

4. Lub rooj

Tus kheej-tsim dual-axis direct-drive cradle turntable yog nruab nrog ib tug high-precision absolute encoder thiab yog txias los ntawm ib tug dej txias ntawm qhov kub thiab txias. Nws muaj qhov zoo ntawm siab rigidity, siab precision, thiab siab dynamic teb. Lub rooj ua haujlwm tau txais 5-18mm radial T-slots, thiab qhov tso cai thauj khoom yog 2000kg (txoj kev sib npaug)

5. cuab yeej magazine

Cov cuab yeej magazine txais BT50 kab rov tav saw servo cuab yeej magazine, uas tuaj yeem ua tau 30 yam cuab yeej.

6. Tag nrho kaw lub voj tawm tswv yim system

X, Y, Z linear axes yog nruab nrog HEIDENHAIN LC195S tus nqi grating tus pas ntsuas; A thiab C rotary ntxhuav yog nruab nrog HEIDENHAIN RCN2310 tus nqi lub kaum ntse ntse encoders kom paub txog tag nrho kaw-loop tawm tswv yim ntawm 5 pub axes, kom lub tshuab muaj siab precision thiab siab precision Retention.

7. Cua txias thiab pneumatic system

Nruab nrog loj txaus txias twj tso kua mis thiab lub tank dej kom txaus txias rau cov cuab yeej thiab workpieces. Lub taub hau kawg lub ntsej muag yog nruab nrog lub tshuab cua txias, uas tuaj yeem tswj tau los ntawm M code lossis tswj vaj huam sib luag.

Nruab nrog lub tshuab dej txias rau qhov txias txias, kom ntseeg tau tias lub tshuab hluav taws xob thiab lub tshuab hluav taws xob ncaj qha tau ua haujlwm zoo thiab tuaj yeem ua haujlwm tau ntev.

Lub tshuab pneumatic tau txais cov khoom siv pneumatic rau kev lim dej, thiab paub txog kev ua haujlwm ntawm kev tu thiab tshuab lub taper qhov ntawm spindle, tiv thaiv huab cua foob ntawm spindle bearing, thiab tshuab thiab tu tus kav grating.

8. Centralized lubrication system

Lub swb thaiv ntawm cov lus qhia kev tsheb nqaj hlau thiab cov txiv ntoo ntawm lub pob ntsia hlau yog txhua yam lubricated nrog cov roj nyias, thiab cov roj lubrication tau muab tsis tu ncua thiab ntau kom ntseeg tau tias qhov tseeb thiab ruaj khov ntawm lub pob ntsia hlau thiab cov lus qhia kev tsheb nqaj hlau.

9. Roj thiab roj lubrication system

Lub tshuab hluav taws xob ntxaiv yog nruab nrog cov khoom siv roj thiab roj lubrication, uas tuaj yeem ua tiav lubricate thiab txias ntxaiv. Lub sensor tuaj yeem muab lub tswb ceeb toom tsis zoo, uas tuaj yeem ua kom cov ntxaiv tuaj yeem ua haujlwm ruaj khov ntawm kev kub ceev rau lub sijhawm ntev.

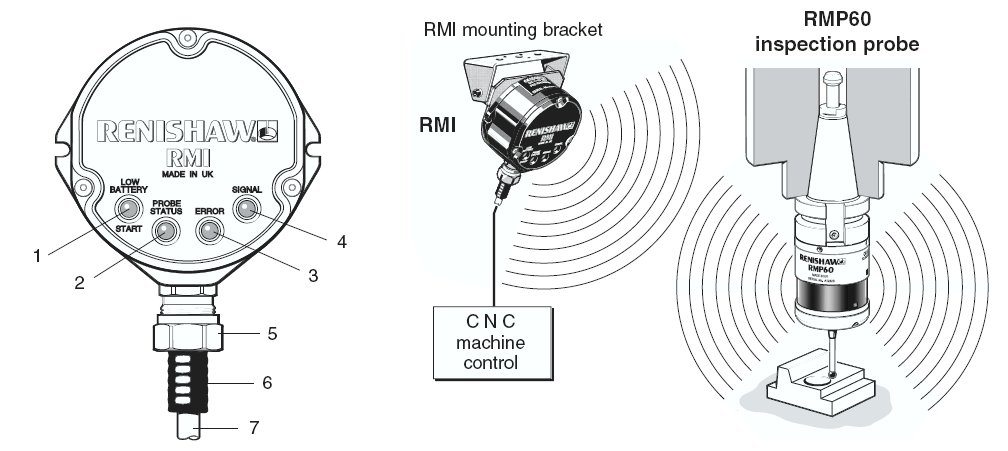

10. Workpiece ntsuas qhov system

Lub tshuab yog nruab nrog Renishaw RMP60 xov tooj cua sojntsuam, siv nrog RMI receiver, kev ua haujlwm zaus yog 2400 MHz rau 2483.5 MHz, qhov ntsuas ib-txoj kev rov ua dua yog tsawg dua lossis sib npaug li 1um (480mm / min ntsuas ceev, siv ib qho 50mm stylus), thiab qhov ua haujlwm kub yog 5 ° C txog 55 ° C.

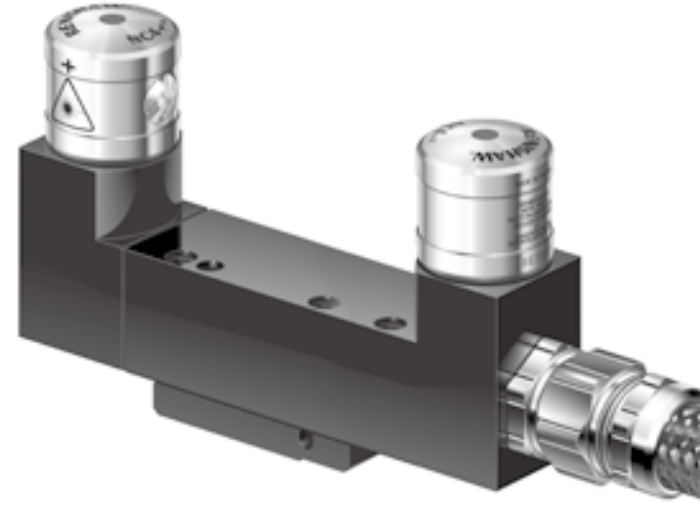

11. Cov cuab yeej ntsuas qhov system

Lub tshuab yog nruab nrog Renishaw NC4 laser cuab tam setter, ntsuas repeatability yog ± 0.1um, thiab ua hauj lwm kub yog 5 ° C rau 50 ° C.

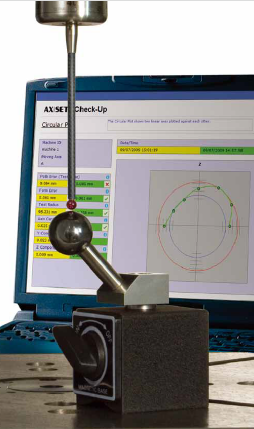

12. Tsib-axis precision calibration muaj nuj nqi

Lub tshuab tau nruab nrog Renishaw's AxiSet Check-Up Rotary Axis Line Checker cov khoom, ua ke nrog cov khoom ntsuas ntsuas RMP60, ua rau cov neeg siv tshuab tau nrawm thiab raug kuaj xyuas cov xwm txheej ntawm cov axis teb thiab txheeb xyuas cov teeb meem tshwm sim los ntawm qhov kub thiab av noo hloov, kev sib tsoo tshuab lossis hnav thiab tsim kua muag. teeb meem, tuaj yeem kho sai sai thiab nrhiav kev kuaj xyuas kev ua tau zoo, ntsuas ntsuas thiab saib xyuas seb cov tshuab ua haujlwm hloov pauv li cas raws sijhawm.

13. tshuab tiv thaiv

Lub tshuab txais kev tiv thaiv npog tag nrho uas ua tau raws li cov qauv kev nyab xeeb los tiv thaiv kev sib tsoo ntawm cov coolant thiab chips, ua kom muaj kev nyab xeeb, thiab muaj qhov zoo nkauj zoo nkauj. Lub X-kev taw qhia ntawm lub tshuab yog nruab nrog ib tug armored tiv thaiv npog, uas muaj peev xwm tiv thaiv cov kev taw qhia rail thiab pob ntsia hlau.

14. tshuab ua hauj lwm tej yam kev mob

(1) Fais fab mov: 380V ± 10% 50HZ ± 1HZ peb-theem alternating tam sim no

(2) Ambient kub: 5 ℃ -40 ℃

(3) Qhov kub thiab txias: 20 ℃ ± 2 ℃

(4) txheeb ze humidity: 20-75%

(5) Huab cua qhov siab: 6 ± 1 bar

(6) Huab cua ntws: 500L / min

15. Muaj nuj nqi qhia txog CNC system

Siemens 840Dsl.730 CNC system configuration

| Yam khoom

| Lub npe

| Lus hais

|

| System ua haujlwm | Yam tsawg kawg nkaus pulse sib npaug | Linear axis 0.001 hli, rotary axis 0.001 ° |

| Pub tus nqi ib feeb / kiv puag ncig | ||

| Pub thiab ceev traverse | ||

| Feedrate override 0 ~ 120% | ||

| Spindle ceev txwv | ||

| Spindle tas li ceev txiav | ||

| Spindle saib xyuas | ||

| Spindle override 50 ~ 120% | ||

| Spindle ceev zaub | ||

| FRAME | Paub txog kev sib koom ua ke kev hloov pauv thiab bevel machining | |

| Direct / indirect ntsuas qhov system hloov | ||

| Saib ua ntej lossis saib ua ntej ua haujlwm | ||

| Lead ntsia hlau pitch yuam kev them nyiaj | ||

| Kev ntsuas qhov system yuam kev | ||

| Quadrant yuam kev Compensation | ||

| Backlash them nyiaj | ||

| Kev tswj cov cuab yeej | ||

| Hardware Configuration | Tus lej tswj axes | X, Y, Z, A, C tsib txoj haujlwm axis thiab ib lub ntsiab axis |

| Simultaneous tswj tus naj npawb ntawm axes | X, Y, Z, A, C tsib-axis txuas | |

| axis npe | X, Y, Z, A, C, SP | |

| saib xyuas | 15 "xim LCD zaub, tso saib cov ntawv hauv Suav / Askiv | |

| Kev ua haujlwm vaj huam sib luag | OP015 tag nrho muaj nuj nqi CNC keyboard | |

| txiv neej-tshuab kev sib txuas lus interface | Standard configuration TCU | |

| Tshuab tswj vaj huam sib luag | SINUMERIK MCP 483C PN tswj vaj huam sib luag, 50 txhua yam yuam sij nrog LED, nrog PROFINET, Muaj Ethernet interface | |

| Handheld operating unit | ||

| Standard keyboard interface | ||

| Ethernet interface | Integrated on NCU (qhib rhiav kev sib tham ua haujlwm) | |

| USB chaw nres nkoj | 3 x 0.5 A USB integrated ntawm TCU | |

| PLC program | PLC317-3PN/DP | |

| Interpolation muaj nuj nqi | Pub ncua | |

| xov txiav | ||

| Simultaneous txiav | ||

| Peb-coordinate linear interpolation | ||

| Arbitrary ob-coordinate ncig interpolation | ||

| Helical interpolation | ||

| Tapping / Rigid Tapping | ||

| programming | Ntau dhau chamfering / rounding | |

| program editor | Ua raws li DIN66025 tus qauv, nrog rau qib siab cov lus programming nta | |

| Tsis muaj tseeb los yog incremental programming | ||

| User variable, settable | ||

| Program jumps thiab ceg | ||

| macro program | ||

| Coordinate system translation thiab rotation | ||

| Simultaneous programming thiab machining | ||

| Txoj kev qhia kom rov qab mus rau qhov chaw siv | ||

| Contour programming thiab cov kaus poom cycle programming | ||

| Mirroring thiab scaling | ||

| xaiv dav hlau | ||

| Workpiece coordinate system | ||

| Drilling thiab milling kaus poom lub voj voog | ||

| Zero offset | ||

| thaiv kev tshawb nrhiav | ||

| Kev tshawb nrhiav tus lej | ||

| Kev kho keeb kwm yav dhau | ||

| kev tiv thaiv | ||

| Xaiv qhov kev pab cuam los ntawm cov npe | ||

| Arithmetic thiab trigonometric muaj nuj nqi | ||

| Kev sib piv thiab kev ua haujlwm zoo | ||

| Tsib-axis machining software pob | Tsib-axis transformation; tsib-axis cuab tam them nyiaj; Kev sib hloov ua haujlwm nyob ib puag ncig lub cuab yeej chaw (RTCP) | |

| Kev tiv thaiv kev nyab xeeb muaj nuj nqi | Programmable machining cheeb tsam txwv | |

| Program xeem muaj nuj nqi | ||

| nres xwm ceev | ||

| Software txwv kev saib xyuas | ||

| Contour saib xyuas | ||

| Contour collision detection | ||

| Kev soj ntsuam zoo li qub | ||

| Saib xyuas qhov chaw | ||

| kev soj ntsuam ceev | ||

| Kev txwv thaj chaw ua haujlwm | ||

| torque txwv | ||

| Kev nyab xeeb muaj nuj nqi Clock xyuas ntsuas Circuit Court, overheating, roj teeb, voltage, nco, txwv keyboards, kiv cua xyuas | ||

| Txoj kev ua haujlwm | AUTOMATIC | |

| JOG (manual) kho | ||

| Handwheel ua haujlwm | ||

| MDA cov ntaub ntawv nkag | ||

| NC thiab PLC kev kuaj mob nrog cov ntawv nyeem, tshuaj ntsuam xyuas | ||

| kev ua haujlwm thiab tso saib | Self-diagnostic function zaub | Xws li hom REF, hom incremental (x1, x10, x100) |

| Tam sim no qhov chaw tso saib | ||

| Graphical zaub | ||

| program tso saib | ||

| program yuam kev zaub | ||

| Kev ua haujlwm yuam kev tso saib | ||

| Qhov tseeb txiav ceev zaub | ||

| Suav thiab Askiv zaub mov zaub | ||

| Tswb qhia zaub | ||

| Muaj ntau yam kev qhia M-code | ||

| Txhawb PROFINET tsheb npav cov ntaub ntawv hloov tsheb | ||

| kev sib txuas lus cov ntaub ntawv | USB chaw nres nkoj | NC cov ntaub ntawv, PLC cov ntaub ntawv thiab cov kev pab cuam yog thaub qab rau U disk rau cov ntaub ntawv tawm tswv yim thiab tso tawm |

| Hloov cov ntaub ntawv Ethernet | Los ntawm Ethernet interface |

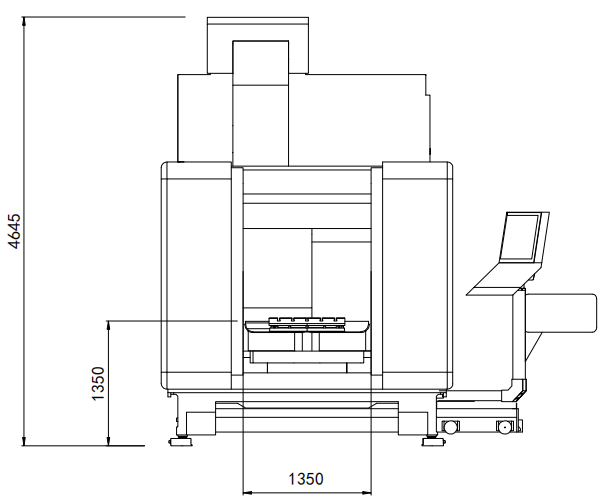

Main parameter

| Yam khoom | Specifications | Chav tsev | |||

| chaw ua haujlwm

| ua hauj lwm rooj loj | φ1000 × 800 | mm | ||

| tso cai siab tshaj load | 2000 | kg | |||

| T-qhov loj me | 5 × 18 | 个 × mm | |||

| ua thaj tsam

| X axis | 1150 | mm | ||

| Y axis | 1300 | mm | |||

| Z axis | 900 | mm | |||

| A-axis | -150-130 | ° | |||

| C axis | 360 | ° | |||

| Qhov deb ntawm spindle kawg lub ntsej muag mus rau lub rooj ua haujlwm | Max | 1080 | mm | ||

| Min | 180 | mm | |||

| Spindle

| Lub khob hliav qab | BT50 | |||

| Rated ceev | 1500 | r / min | |||

| ceev tshaj plaws | 10000 | ||||

| Cov zis torque S1 / S6 | 191/236 ib | Nm | |||

| Spindle lub cev muaj zog S1 / S6 | 30/37 ib | kW | |||

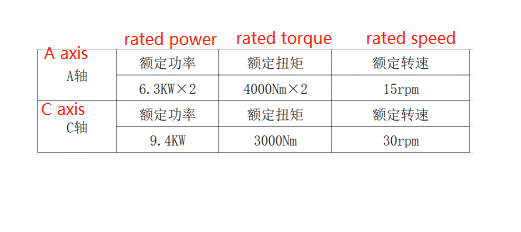

| Axis

| txav ceev ceev | X axis | 25 | m/min | |

| Y axis | 25 | ||||

| Z axis | 25 | ||||

| Turntable siab tshaj plaws ceev | A-axis | 15 | rpm ua | ||

| C axis | 30 | rpm ua | |||

| X / Y / Z axis lub cev muaj zog | 3.1/4.4/2 | kW | |||

| A / C axis Lub cev muaj zog | 6.3 * 2/9.4 | kW | |||

| A-axis | Rated torque | 4000 × 2 | Nm | ||

| C axis | Rated torque | 3000 | Nm | ||

| siab tshaj tus nqi pub | X/Y/Z | 25 | m/min | ||

| A/C | 15/30 ib | rpm ua | |||

| Tool magazine

| Tool magazine daim ntawv | kab rov tav | |||

| txoj kev xaiv cuab yeej | Ob-txoj kev ze tshaj plaws xaiv cov cuab yeej | ||||

| Cov cuab yeej magazine muaj peev xwm | 30 | T | |||

| Cov cuab yeej siv ntev tshaj plaws | 400 | mm | |||

| Qhov siab tshaj plaws qhov hnyav | 20 | kg | |||

| Qhov siab tshaj plaws cutter taub hau txoj kab uas hla | puv riam | φ125 | mm | ||

| Cov cuab yeej uas nyob ib sab | φ180 | mm | |||

| txoj hauj lwm precision | Tus txheej txheem tswj hwm | GB / T20957.4 (ISO 10791-4) | |||

| X-axis/Y-axis/Z-axis | 0.008/0.008/0.008 | mm | |||

| B axis / C axis | 8 ″ / 8 ″ | ||||

| rov ua dua txoj hauj lwm precision | X-axis/Y-axis/Z-axis | 0.006/0.006/0.006 | mm | ||

| B axis / C axis | 6 ″ / 6 ″ | ||||

| Tshuab hnyav | 33 000 | kg | |||

| tag nrho hluav taws xob muaj peev xwm | 80 | KVA | |||

| tshuab qhia qhov loj | 7420 × 4770 × 4800 hli | mm | |||

Configuration List

Txuj

|

| 1. Cov khoom tseem ceeb (nrog rau lub hauv paus, kem, kab teeb, swb phaj, spindle box) |

| 2. X, Y, Z peb-axis pub system | |

| 3. Cradle type turntable AC1000 | |

| 4. Hluav taws xob spindle | |

| 5. Hluav taws xob tswj qhov system (xws li hluav taws xob txee, fais fab module, servo module, PLC, ua haujlwm vaj huam sib luag, zaub, chav tuav tes, hluav taws xob txee cua txias, thiab lwm yam.) | |

| 6. Hydraulic system | |

| 7. Pneumatic system | |

| 8. Centralized lubrication system | |

| 9. Dej txias | |

| 10. Chip conveyor, dej tank, nti collector | |

| 11. Grating kav | |

| 12. Rail tiv thaiv npog | |

| 13. tshuab zuag qhia tag nrho kev tiv thaiv npog | |

| 14. Workpiece ntsuas qhov system | |

| 15. Cov cuab yeej teeb tsa | |

| 16. Tsib-axis precision calibration muaj nuj nqi | |

|

| 1. 1 daim ntawv pov thawj ntawm kev ua raws 2. Ntim daim ntawv 1 daim 3. 1 txheej tshuab phau ntawv (electronic version) 4. tshuab thaub qab cov ntaub ntawv 1 teeb (U disk) 5.840D alarm diagnosis manual 1 set (electronic version) / 828D diagnosis guide 1 daim (electronic version) 6.840D milling operation manual 1 daim (electronic version) / 828D operation manual 1 copy (electronic version) 840D programming phau ntawv 1 theem pib (electronic version) / 828D programming phau ntawv 1 (electronic version) |

| Yam khoom | Hom |

| X / Y / Z axis lub cev muaj zog thiab tsav | Siemens, Lub teb chaws Yelemees |

| zog chain | German igus |

| ntsia hlau bearing | Nyiv NSK/NACHI |

| Cov Lus Qhia Linear | Schneeberg, Lub teb chaws Yelemees |

| Tool magazine | Okada |

| reducer | STOBER, Lub teb chaws Yelemees |

| Centralized lubrication | Nyiv |

| Pob ntsia hlau | SHUTON, Spain |

| Pneumatic Cheebtsam | Nyiv SMC |

| Electric txee cua txias | Tuam Tshoj |

| dej txias | Tuam Tshoj |

| grating kav | HEIDENHAIN, Lub teb chaws Yelemees |

| Workpiece ntsuas qhov system | Renishaw, UK |

| Cov cuab yeej ntsuas qhov system | Renishaw, UK |

| Patrs nrog tshuab | Specifications | Ntau |

| Tshuab txaj hlau |

| 8set ib |

| Anchor bolts |

| 8set ib |

| nplhaib | M30 | 2 qab |

| nplhaib | M36 | 2 qab |

| tshem tawm |

| 1set ib |

| Allen tus yuam sij | 10 | 1 |

| Allen tus yuam sij | 12 | 1 |

| Allen tus yuam sij | 14 | 1 |

| Allen tus yuam sij | 19 | 1 |

| Z-axis mount |

| 1 |

| X-axis mount |

| 1 |

| Y-axis kho |

| 1 |

Ua tsaug rau koj mloog!