Tuam Tshoj Vmc850 CNC Milling Tshuab CNC Tshuab 3 Axis 4 Axis 5 Axis

Kev ua tiav cov neeg siv khoom yog peb lub hom phiaj tseem ceeb. Peb txhawb nqa ib theem ntawm kev tshaj lij, zoo heev, kev ntseeg siab thiab kev pabcuam rau Sab saum toj Qib Tuam Tshoj Vmc850 CNC Milling TshuabCNC tshuab3 Axis 4 Axis 5 Axis, Tag nrho cov kev xav thiab kev daws yuav tau txais txiaj ntsig zoo heev! Kev koom tes zoo tuaj yeem txhim kho peb ob leeg mus rau kev nce qib zoo dua!

Kev ua tiav cov neeg siv khoom yog peb lub hom phiaj tseem ceeb. Peb txhawb nqa ib theem ntawm kev tshaj lij, zoo heev, kev ntseeg siab thiab kev pabcuam rauTuam Tshoj CNC Milling Tshuab, CNC tshuab, Tam sim no peb lub network muag khoom tau loj hlob tsis tu ncua, txhim kho kev pabcuam zoo kom tau raws li cov neeg siv khoom xav tau. Yog tias koj txaus siab rau txhua yam khoom, thov hu rau peb txhua lub sijhawm. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog koj nyob ze yav tom ntej.

Tshuab Nta

1.Product manual

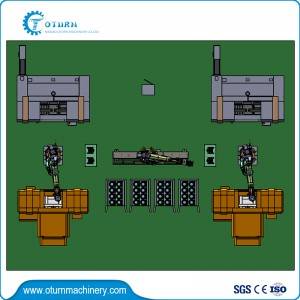

SG1614 tau dhau los ua cov txheej txheem sib dhos tshwj xeeb ntawm lub tuam txhab thiab tau ua kom pom kev ua haujlwm siab, ua haujlwm siab thiab ruaj khov hauv kev ua lag luam.

Cov cuab yeej siv tshuab zoo tshaj plaws tau xav txog hauv kev lag luam pwm tsim, kev lag luam tsheb tsim, khoom siv kho mob precision, kev lag luam aerospace thiab lwm yam. Nrog cov thev naus laus zis zoo thiab kev ua haujlwm zoo ntawm lub tshuab, lawv tau txais kev qhuas zoo thiab tau txais kev txhawb nqa dav dav thiab lees paub los ntawm cov neeg siv khoom tshiab thiab qub. Thiab ntseeg.

2. Kev Taw Qhia Kev Ua Haujlwm

Siab rigidity:

Lub fuselage qauv txais kev txhawb nqa tag nrho, thiab lub computer simulation

Kev tshuaj xyuas lub cev qauv yog ua tiav rau qhov tseem ceeb ntawm kev ntxhov siab. Lub tshuab puag

bears lub zog ntawm 4000kgf thiab nws deformation yog nyob rau hauv 0.01 hli. Nws muaj peev xwm tiv taus tus

rigidity yuav tsum tau txiav.

Lub kem txais ib qho kev sib koom ua ke gantry qauv thiab nthuav qhov chaw txhawb nqa kom ntseeg tau tias lub spindle thiab ntsug high-ceev ua haujlwm, uas tuaj yeem ua rau kom muaj zog

machining rigidity thiab stability ntawm kev pab cuam lub neej. Nruab nrog lub siab ceev spindle, nws tuaj yeem yooj yim ua tau raws li cov kev xav tau ntawm cov hlau tawv tawv tawv.

High precision:

Thawj-chav high-precision roller linear qhia tuaj ntawm lub teb chaws Yelemees thiab Taiwan

pob ntsia hlau yog siv los xyuas kom meej qhov geometric precision thiab positioning precision ntawm tag nrho cov qauv, stability thiab kev pab lub neej.

Lub servo tsav siv German thawj-chav hom, uas yog superior rau cov neeg sib tw hauv

tib theem nyob rau hauv cov nqe lus ntawm cov zis torque thiab qhov tseeb qhov tseeb qhov tseeb.

Lub high-speed built-in spindle thiab tsim qauv tsim kom paub meej tias cov

spindle tuaj yeem tuav ruaj khov thiab raug ua haujlwm thaum lub sijhawm ua haujlwm siab nrawm

kev ua haujlwm, thiab tuaj yeem ua tiav high-precision thiab high-gloss ua cov teebmeem thaum lub sijhawm txiav.

high efficiency:

Qhov siab tshaj plaws kev khiav hauj lwm ceev ntawm peb-axis ntawm lub tshuab cuab tam tuaj yeem ncav cuag 24m / min, thiab txiav ceev tuaj yeem ncav cuag qhov ntau ntawm 0-10M / min, uas ua rau lub sijhawm ua haujlwm luv thiab txhim kho kev ua haujlwm. Lub spindle ua kom cov zis siab torque

thiab qhov raug zoo thiab kev ntseeg tau zoo thaum lub sijhawm ua haujlwm txiav. Nyob rau hauv high-speed txiav tej yam kev mob, lub machining cov hauj lwm yuav ua kom tiav nrog zoo efficiency.

Lub tshuab hluav taws xob ceev ceev txhawb nqa qhov kev twv ua haujlwm ntawm cov peev txheej loj machining cov kev pab cuam, thiab tuaj yeem kwv yees 250-ntu cov lus qhia ua haujlwm kom ntseeg tau tias yuav tsis muaj kev ncua ntev hauv kev kub ceev txiav, uas tuaj yeem txuag lub sijhawm sib kis thiab nce kev ua haujlwm ntawm 20. %.

Specification

| Yam khoom | SIB 1190 | SIB 1310 | SIB 1614 | TIAB SA 2515 |

| X axis mus ncig (mm) | 1100 | 1300 | 1600 | 2500 |

| Y axis mus ncig (mm) | 900 | 1000 | 1400 | 1500 |

| Z axis mus ncig (mm) | 500 | 700 | 760 ib | |

| Qhov chaw ua haujlwm (ntev x dav) (mm) | 1100 × 900 hli | 1400 × 900 hli | 1700 × 1300 hli | 2700 × 1300 hli |

| Qhov deb ntawm rooj saum npoo mus rau spindle kawg nto (mm) | 330-830 : kuv | 250-950 Nws | 200-960 : kuv | |

| Qhov rooj dav (mm) | 1100 | 1410 | 1525 | |

| T-qhov (mm) | 5 x 18 x 175 | 7 x 22 x 185 | 8 x 22 x 150 | |

| Max loading (Kg) | 1500 | 2000 | 4000 | 6000 |

| Spindle ceev | 15000RPM (Direct) | |||

| Spindle taper | HSK-A63 | |||

| Spindle zog (Kw) | 11.7 ib | 20 | ||

| ATC | 24 | |||

| Tswj qhov system | Siemens 828 D | |||

| Tshuab loj (mm) | 3776x2279x2752 ua | 4031x2280x2752 | 4900x3152x3350 | 7460x4510x3600 |

| Tshuab hnyav (T) | 8 | 9.5 ib | 14 | 23 |

Configurations

| Txuj | xaiv tau |

| Tswj qhov system: Siemens 828D | Tswj system: Mitsubishi M80A. FANUC 0i M |

| Spindle txias system | Ua hauv spindle 20000rpm (HSK-A63) |

| Pneumatic.lubrication system | Spindle nplhaib txau txias |

| Full enclosure nrog top cover | CNC rotary rooj (Lub 4th axis) |

| 3-xim teeb liab teeb, ua haujlwm teeb | Workpiece sojntsuam |

| Txheem accessories | Toolsetter |

| Cov cuab yeej pabcuam | Roj skimmer |

| Helix nti conveyor | Linear nplai |

| Cua txias ntawm hluav taws xob txee |

Kev ua tiav cov neeg siv khoom yog peb lub hom phiaj tseem ceeb. Peb txhawb nqa ib theem ntawm kev tshaj lij, zoo heev, kev ntseeg siab thiab kev pabcuam rau Sab saum toj Qib Tuam Tshoj Vmc850 CNC Milling TshuabCNC tshuab3 Axis 4 Axis 5 Axis, Tag nrho cov kev xav thiab kev daws yuav tau txais txiaj ntsig zoo heev! Kev koom tes zoo tuaj yeem txhim kho peb ob leeg mus rau kev nce qib zoo dua!

Kev ua tiav cov neeg siv khoom yog peb lub hom phiaj tseem ceeb. Peb txhawb nqa ib theem ntawm kev tshaj lij, zoo heev, kev ntseeg siab thiab kev pabcuam rau Sab saum toj Qib Tuam Tshoj Vmc850 CNC Milling TshuabCNC tshuab3 Axis 4 Axis 5 Axis, Tag nrho cov kev xav thiab kev daws yuav tau txais txiaj ntsig zoo heev! Kev koom tes zoo tuaj yeem txhim kho peb ob leeg mus rau kev nce qib zoo dua!

Qib SiabTuam Tshoj CNC Milling Tshuab, CNC Tshuab, Tam sim no peb cov kev muag khoom tau loj hlob tsis tu ncua, txhim kho kev pabcuam zoo kom tau raws li cov neeg siv khoom xav tau. Yog tias koj txaus siab rau txhua yam khoom, thov hu rau peb txhua lub sijhawm. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog koj nyob ze yav tom ntej.