CovTshwj xeeb Valve TshuabFeem ntau yog siv hauv kev ua haujlwm Valve ( Npauj Npaim Valve / Rooj vag valve / Pob valve / ntiaj teb valve, thiab lwm yam ..), Lub cev twj tso kua mis, Nws pib qhov chaw, Kev tsim kho tshuab thiab lwm yam.

Nws ua haujlwm rau ntau qhov kev ua haujlwm sib txawv, xws li: Lub ntsej muag kawg, lub voj voog sab nrauv, pem hauv ntej ntug, puab lub qhov, grooving, ntsia hlau xov, Bore-qhov thiab kheej kheej.Nws tuaj yeem paub automation, siab precision, ntau yam thiab ntau lawm.Widely siv nyob rau hauv lub valve kev lag luam.

Txog ntawmvalve kev lag luam

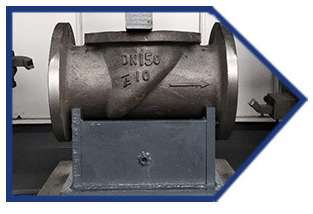

Valves yog cov khoom siv hauv cov kav dej siv los qhib thiab kaw cov kav dej, tswj kev ntws, kho thiab tswj qhov ntsuas qhov ntsuas (kub, siab, thiab ntws) ntawm cov khoom nruab nrab.Raws li nws txoj haujlwm, nws tuaj yeem muab faib ua lub kaw-off valve,kos valve, regulating valve, thiab lwm yam.

Lub valve yog ib qho kev tswj xyuas nyob rau hauv cov kua conveying system.Nws muaj lub luag haujlwm ntawm kev txiav tawm, kev tswj hwm, kev hloov pauv, kev tiv thaiv kev thim rov qab, kev ruaj khov, kev hloov pauv lossis kev dhau mus, thiab kev txo qis.Valves siv nyob rau hauv kev tswj cov kua dej, xws li los ntawm qhov yooj yim tshaj plaws kaw-off li qub mus rau ntau yam li qub siv nyob rau hauv tsis tshua muaj siab tsis siv neeg tswj systems, muaj ntau yam ntawm ntau yam thiab specifications.

Valves tau siv dav hauv ntau qhov chaw.Feem ntau yog roj av, metallurgy, hluav taws xob fais fab, kev txuag dej, kev tsim kho hauv nroog, hluav taws kub sib tua, tshuab, thee, zaub mov, thiab lwm yam.

Muaj

Dab tsi yog qhov zoo ntawmTshwj xeeb Valve Tshuabhauv kev lag luam valve

√Drilling txais ntau hom axis, thiab kev ua haujlwm tau zoo dua ob peb zaug.

√ Ua tiav ob lossis peb lub taub hau ua haujlwm tib lub sijhawm thaum ua tiav kom paub txog tus qauv thiab kev ua haujlwm siab ntawmtwj tso kua mis valve ua.

√Exclusive patented numerical control system, tag nrho automated ua haujlwm.

Peb pom zoo tshwj xeeb Valve Tshuab

Peb cov lus pom zoodedTshwj xeeb Valve Tshuab

1. Tshuab lub cev

Lub tshuab lub cev yog ua los ntawm tag nrho cov zoo grey hlau casting, ntxhib machining, xov, thiab peb tempering aging kev kho mob kom tshem tawm tag nrho cov residual kev nyuaj siab.Qhov saum npoo ntawm cov lus qhia rail

Nws tau txais kev kho mob super-suab zaus quenching thiab ua tiav los ntawm high-precision qhia kev tsheb nqaj hlau sib tsoo kom ntseeg tau tias qhov tseeb, nruj, thiab ruaj khov ntawm lub tshuab cuab yeej.√

2.Tshwj xeeb Valve tshuab

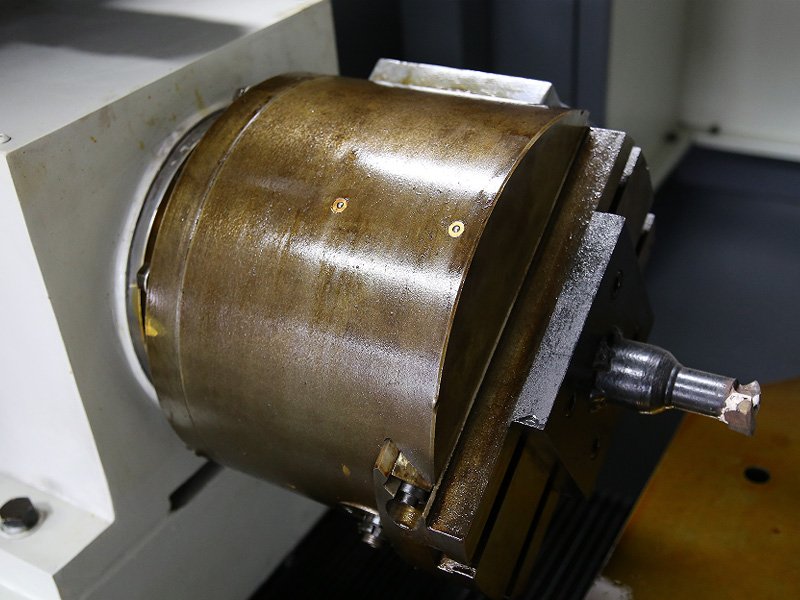

Lub taub hau Box

Lub taub hau lub thawv yog ua los ntawm cov khoom zoo, thiab lub ntsiab ncej yog ua los ntawm 20GrMnTAi, uas tau raug forged, quenched, thiab tempered, carburized thiab quenched, thiab ntxiv los ntawm high-precision sab hauv thiab sab nrauv cylindrical grinder.

Lub bearing txais yuav high-precision ob-kab cylindrical cov menyuam bearings los xyuas kom meej lub rigidity thiab precision ntawm spindle.Lub ntsiab ncej txais kev hloov pauv peb-theem nrawm nrog lub tshuab hluav taws xob siab kom ua tiav qhov nrawm

Loj torque, tuaj yeem dais qhov hnyav txiav, txhim kho kev ua haujlwm zoo.√

7. Centralized lubrication ntaus ntawv

Lub tshuab lubrication yog nruab nrog Nanjing Beqier kev ua haujlwm lubrication ntaus ntawv, uas niaj zaus tso cov roj lubricating mus rau hauv qhov chaw lubrication ntawm txhua qhov txav, tshem tawm cov kev ua haujlwm tsis txaus ntseeg.

Txhim kho lub neej kev pab cuam ntawm lub tshuab cuab yeej.√

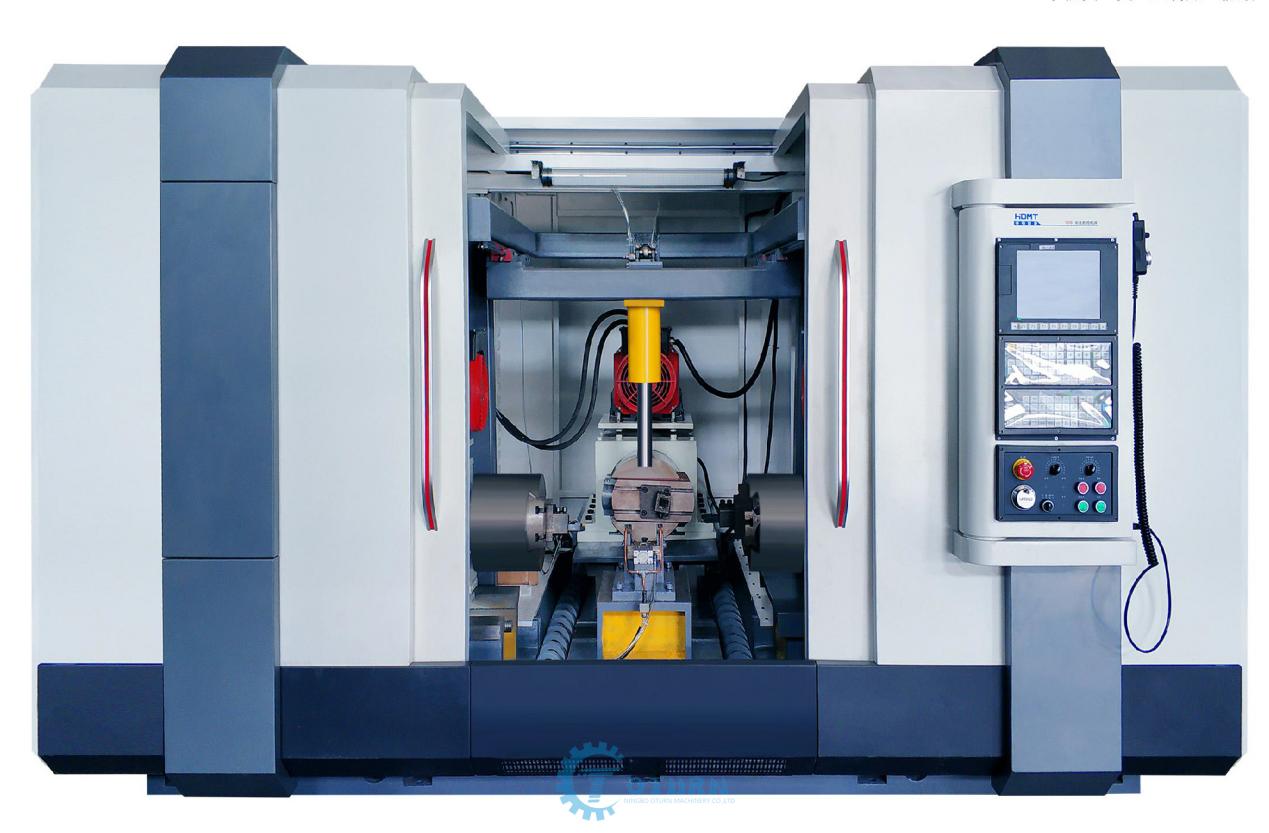

Ob lub taub hau CNC tshuab

Npauj npaimvalve tshwj xeeb tshuab

HDCX800 tig-milling composite machining chaw,npauj npaim valvetshwj xeeb ua tshuab cuab tam yog tsuas yog siv nyob rau hauv npauj npaim li qub thiab xoom

Rau kev ua haujlwm ntawm qhov chaw, engineering machinery thiab lwm yam, lub ntsej muag kawg, lub voj voog sab nrauv, lub hau npog, lub qhov hauv lub qhov, zawj, xov, taper qhov thiab cov duab kheej kheej ntawm lub workpiece tuaj yeem ua tiav.

Tig.Cov txheej txheem ua haujlwm yog tswj hwm los ntawm GSK CNC system, uas tuaj yeem paub txog automation, siab precision, ntau yam, thiab ntau lawm.

lub ntsiab feature

1. Lub HDCX800 Tshwj xeeb Valve Tshuab yog txhua yam tswj los ntawm GSK CNC system, uas tuaj yeem pom tau los ntawm kev sib txuas dual-axis.

Kev ua ntawm taper qhov, threads, thiab spherical txheej txheem.Nws cov CNC system yog sib xws, muaj zog, thiab yooj yim rau kev khiav lag luam.

2. Cov kev taw qhia kev tsheb nqaj hlau ntawm cov khoom pub swb yog ua los ntawm cov khoom zoo grey cam khwb cia hlau, uas tau raug peb tempering aging kev kho mob tom qab roughcasting thiab tiav kom tshem tawm tag nrho cov seem sab hauv kev ntxhov siab.

Qhov saum npoo tau txais kev kho mob super-suab zaus quenching thiab hardness ncav cuag HRC55.Lub precision, rigidity, thiab stability ntawm lub tshuab cuab yeej yog guaranteed los ntawm high-precision rail sib tsoo.

3. Cov kis tau tus mob yog tsav los ntawm precision pob screws thiab interpolation ntsuas yog siv los tshem tawm qhov khoob, kom ntseeg tau tias kev sib kis tau zoo thiab kev ua haujlwm ntawm lub tshuab cuab yeej.

4. Lub powerhead txais yuav peb-theem phau ntawv kis tau tus mob nrog lub siab-lub zog lub cev muaj zog kom ua tiav qis-ceev thiab siab-torque, tuaj yeem tiv taus hnyav txiav, thiab txhim kho kev ua haujlwm zoo.

5. Cov cuab yeej siv hydraulic tsis siv neeg clamping los txhim kho kev ua haujlwm thiab txo tus kheej kev siv zog.

6. HDCX800 Tshwj xeeb Valve Tshuab,npauj npaim valve tshwj xeeb ua tshuablub cuab yeej siv lub hauv paus lubrication los xyuas kom meej tias txhua qhov txav mus yog siab lubricated thiab txhim kho lub tshuab cuab yeej.

Tshwj xeeb Valve Tshuab Qauv

Lub taub hau fais fab

Lub taub hau lub taub hau lub cev yog ua los ntawm cov khoom zoo, thiab lub ntsiab ncej yog ua los ntawm 20GrMnTAi cov khoom, uas yog ua tiav los ntawm forging, quenching, thiab tempering, carburizing, thiab quenching, thiab high-precision sab hauv thiab sab nrauv cylindrical grinders.

Cov kabmob txais NN30 series high-precision ob-kab cylindrical cov menyuam bearings los xyuas kom meej lub rigidity thiab precision ntawm spindle.

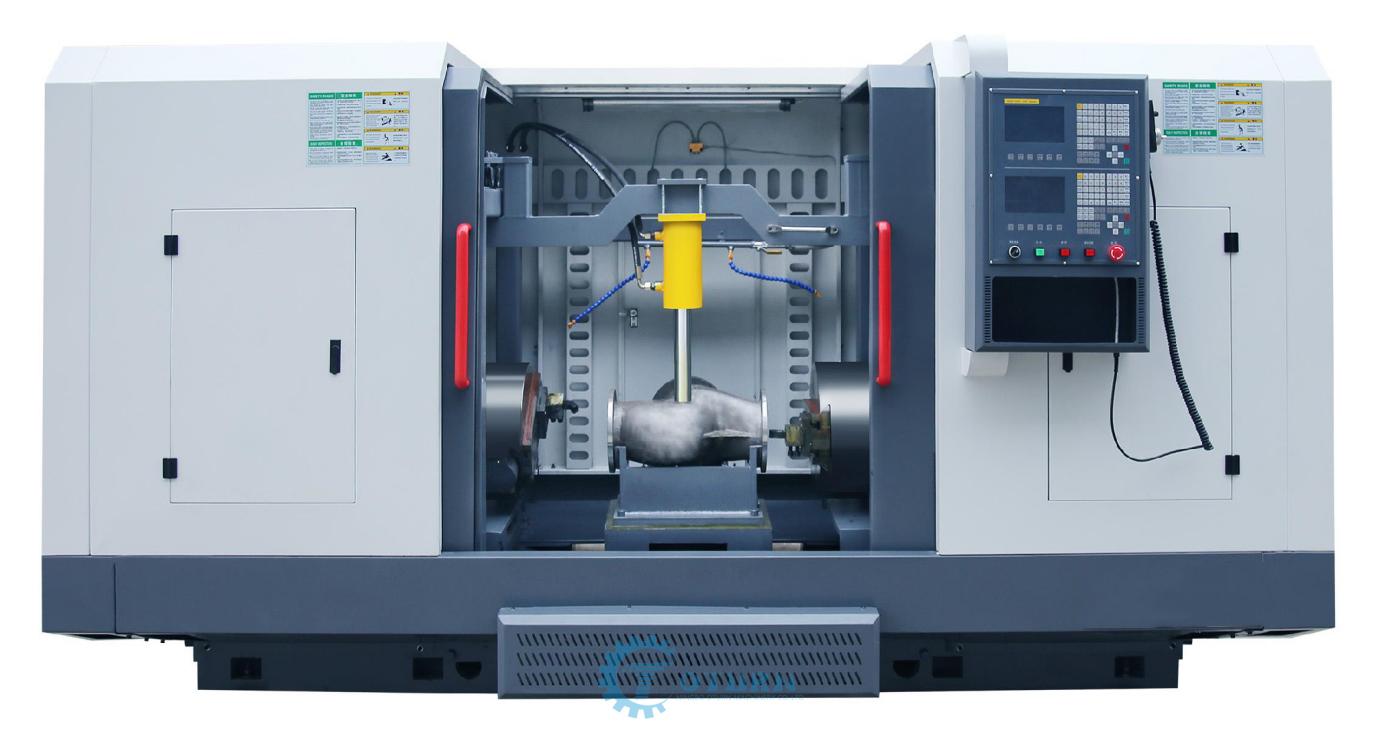

Lub rooj ua haujlwm

Lub worktable yog ib lub workbench tshwj xeeb tsim tshwj xeeb raws li cov khoom ua tiav.Qhov chaw thaiv qhov chaw thiab qhov chaw pins yog tag nrho cov quenched kom ntseeg tau tias qhov chaw ua haujlwm txhim khu kev qha.

Workpiece clamping adopts phau ntawv clamping los txhim kho kev ua haujlwm thiab txo tus kheej siv zog.Thiab lub rooj ua haujlwm tuaj yeem tig 180 degrees, ib zaug clamping, ib zaug ua tiav tag nrho cov txheej txheem.

Automatic tool change tool magazine

Tag nrho tsis siv neeg CNC cuab yeej hloov pauv cov cuab yeej magazine, uas tuaj yeem tuav 16 cov cuab yeej, 20 cov cuab yeej, 24 cov cuab yeej, thiab lwm yam, uas tau txais kev tswj hwm los ntawm lub kaw lus, nrog cov cuab yeej hloov ceev ceev thiab qhov tseeb.

- Lub taub hau zog

Lub hwj chim lub taub hau txais ib qho tshwj xeeb patented lub cev muaj zog + ntsia hlau qauv, uas muaj cov yam ntxwv ntawm siab precision, siab rigidity, thiab lub neej ntev.

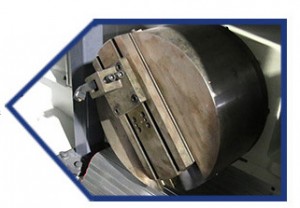

- Tooling

-

Cov cuab yeej yog cov cuab yeej tshwj xeeb tsim tshwj xeeb raws li qhov yuav tsum tau ua.Qhov chaw thaiv qhov chaw thiab qhov chaw pins yog tag nrho cov quenched kom ntseeg tau tias qhov chaw ua haujlwm txhim khu kev qha.Lub workpiece yog clamped los ntawm hydraulic clamping, uas txhim kho cov kev ua tau zoo thiab txo cov kev siv zog ntawm cov neeg ua haujlwm.

- Hluav taws xob txee

Lub txee hluav taws xob txais yuav ib qho kev ywj pheej kaw, nrog kev tswj hwm qhov system, zaus hloov pauv thiab lub tshav dav hlau tswj cov khoom siv hluav taws xob, thiab tau nruab nrog cov cuab yeej cua txias kom ntseeg tau tias cov khoom siv hluav taws xob ntawm lub tshuab cuab yeej ua haujlwm ib txwm thiab tsis txhob nkag mus rau hauv plua plav.

- CNC CTswj System

Nws muaj kev ua haujlwm ntawm ntau txoj kev tswj xyuas tshuab, tsib-axis machining, high-speed thiab high-precision, tig thiab milling, synchronous tswj thiab lwm yam high-end CNC tswj.

Kev xaiv khoom siv:

CNC tswj

cua txias tswj

Tsis siv neeg nti conveyor

Kev tiv thaiv ib nrab / kev tiv thaiv tag nrho

Rau ntau hom li qub, cov txheej txheem sib txawv yog ua tiav.Piv txwv li, kev tsim khoom thiab ntau yam kev npaj yuav tsum tau ua ua ntej ua.Cov kws tsim khoom yuav tsum tau ua cov kev npaj tsim nyog raws li tus txheej txheem tsim ntawm cov khoom nws tus kheej thiab cov txheej txheem tshwj xeeb cov cuab yeej tsim khoom ntawm Huadian valve dav hlau.Lub valve dawb paug qhov chaw tuaj yeem tsim los ntawm cov xuab zeb casting, precision casting lossis xub wax casting thaum tsim khoom.Rau forging los yog vuam txheej txheem, nws yog ib qho tsim nyog yuav tau tsim raws li cov khoom seem.

Covvalve txheej txheem txheej txheemyog complex, thiab tus nqi ntxiv ntawm cov khoom yog tsawg.Qhov zoo ntawm kev siv lub hom phiaj dav dav lossisCNC tshuab cuab yeejtsis tuaj yeem xav txog.Kev ua tiav ntawm lub valve txawm xav tau kev sib xyaw ntawm ntau lub tshuab kom ua tiav cov txiaj ntsig ua haujlwm.Txhua zaus koj hloov qhov loj lossis ntau yam, koj yuav tsum tau kho lub tshuab cuab yeej, thiab tom qab ntawd hloov cov txheej txheem ua tiav los ntawm cov txheej txheem dhau los mus rau cov cuab yeej siv tshuab sib txuam hauv cov txheej txheem tom ntej.Qhov no tsis tsuas yog nce tus nqi tsim khoom, tab sis kuj nkim sijhawm ntau tus nqi.Feem ntau, workpieces uas yuav tsum tau kuj high precision, vim hais tias ntawm ntau yam clamping hloov, ua rau kom lub precision yuam kev ntawm lub workpiece.Yog li cov txiaj ntsig ntawm covvalve dav hlaulawv tus kheej ua pov thawj.

Piv txwv li, raurooj vag li qub, tig ntawm peb sab flanges tuaj yeem ua tiav ntawm ib lub tshuab.Tam sim no, HDMT valve lub tshuab tshwj xeeb tuaj yeem ua tiav ob lossis peb sab ntawm lub valve flange ib zaug, uas yooj yim thiab ua haujlwm tau zoo, thaum cov khoom siv tsoos tsuas yog ib lub flange ntawm lub valve tuaj yeem ua tiav ib zaug, uas yog siv sijhawm ntev. thiab siv zog ua haujlwm.Nyob rau hauv tib txoj kev, lub flange drilling ntawm peb los yog ob sab ntawm lub valve kuj yog raws li tib txoj cai, uas tsis tsuas yog txhim kho cov efficiency, tab sis kuj txo txoj hauj lwm kam rau ntawm lub qhov.

Kev ua haujlwm ntawm lubvalve tshwj xeeb tshuabNws kuj yog qhov yooj yim heev, txhua tus qauv tau paub txog qhov tsis siv neeg tsim, tsuas yog yuav tsum tau nkag mus rau qhov tsis muaj.Qhov no txo qis kev ua haujlwm ntawm phau ntawv, txo cov nqi zog, thiab txuag lub sijhawm thiab kev siv zog.Yog tias muaj kev thauj khoom ntau dhau lossis qee qhov teeb meem tshwm sim thaum lub sijhawm tsim khoom, lub tshuab yuav muab lub tswb tam sim lossis kaw, kom tsis txhob muaj kev puas tsuaj rau lub tshuab kom loj tshaj plaws.

Tom qab lub dav hlau valve tiav lawm, tus neeg teb xov tooj yuav tsum tau tua hluav taws xob cuam tshuam, ua haujlwm zoo ntawm kev tu, thiab siv cov roj nplua nyeem los kho thiab tswj lub dav hlau valve.Muaj ntau yam uas yuav tsum tau them sai sai rau lub sijhawm ua haujlwm ntawm lub tshuab valve tshwj xeeb.Lub tshuab tshwj xeeb valve tsis tuaj yeem ua cov haujlwm xws li kev hloov kho, tshuaj xyuas thiab tshem tawm thaum lub sijhawm ua haujlwm.Thaum lub sijhawm tag nrho cov txheej txheem ntawm kev ua haujlwm ntawm lub tshuab tshwj xeeb valve, cov neeg ua haujlwm thiab cov neeg ua haujlwm yuav tsum tsis txhob tso lawv txoj haujlwm, thiab yuav tsum ua txoj haujlwm zoo ntawm kev saib xyuas.Cov cuab yeej xws li workpieces, fixtures, thiab riam yuav tsum tau clamped kom ruaj khov, txwv tsis pub qee qhov teeb meem ntawm workpiece txav yuav tshwm sim.Kev ua haujlwm tsis zoo tuaj yeem ua rau raug mob tsis tsim nyog.Yog tias rab riam tawg los yog tawg, nws yuav tsum tau hloov lub sijhawm.Hauv cov txheej txheem ntawm kev ua haujlwm ib txwm muaj, peb tsis tuaj yeem kov ncaj qha rau saum npoo ntawm lub workpiece nrog peb txhais tes, thiab peb tsis tuaj yeem tshem tawm cov khoom txaus ntshai xws li txiav nrog peb txhais tes.Qhov no yuav tsis tsuas yog ua mob rau peb txhais tes, tab sis kuj ua rau cov ntaub ntawv hlau ya.Kev huam yuaj rau hauv qhov muag.Thaum lub sijhawm ua haujlwm ntawm lubtshwj xeeb valve dav hlau, koj yuav tsum hnav cov ris tsho sib xws, hnav lub hau ua haujlwm, thiab nco ntsoov muab koj cov plaub hau rau hauv lub hau ua haujlwm.Thaum loading thiab unloading loj workpieces, sim siv lifting khoom, kom tag nrho cov kev khiav hauj lwm yuav coexist ntau tshaj lij, thiab kev nyab xeeb kev ua tau zoo yuav siab dua.

Post lub sij hawm: Sep-22-2021