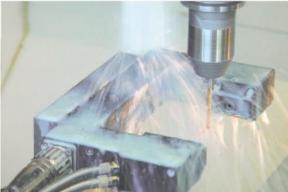

CovCNC machining chawyog ib hom CNC tshuab.Machining chaw kuj muab faib uakab rov tav machining chawthiabntsug machining chaw.

Lub spindle axis (Z-axis) ntawm ntsug machining chaw yog ntsug, uas yog haum rau ua cov npog qhov chaw thiab ntau yam pwm;

Lub spindle axis (Z-axis) ntawm kab rov tav machining chaw yog kab rov tav.Feem ntau, nws tau nruab nrog cov ntawv xov xwm saw-hom cuab yeej nrog lub peev xwm loj dua.Tom qab clamping.Tsis siv neeg ua tiav ntau qhov chaw, kev ua haujlwm ntau, uas yog siv los ua cov khoom siv hauv lub thawv.Lub tshuab siv rau tsib-axis machining feem ntau hu ua tsib-axis tshuab lossis ib Tsib Axis Machining Center.Tsib-axis machining feem ntau yog siv nyob rau hauv aerospace teb los ua lub cev qhov chaw, turbine qhov chaw, thiab impellers nrog txoj cai nkhaus nto.Lub tsib-axis synchronous CNC tshuab tuaj yeem ua cov txheej txheem sib txawv ntawm cov khoom ua haujlwm yam tsis hloov txoj haujlwm ntawm lub tshuab ua haujlwm ntawm lub tshuab cuab yeej, uas tuaj yeem txhim kho kev ua haujlwm zoo ntawm prismatic qhov chaw.

CNC machining chawFeem ntau yog siv rau hauv kev lag luam hauv qab no:

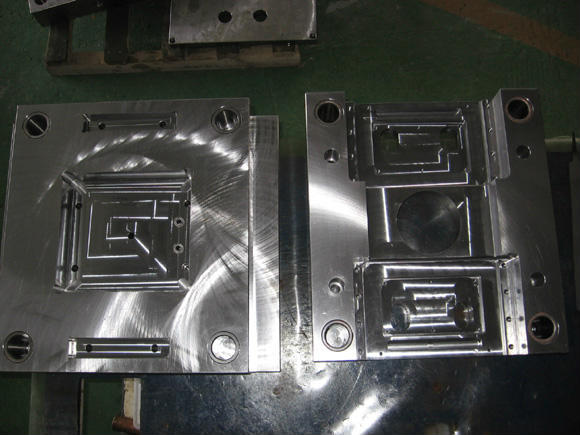

1. Pwm

Pwm kev lag luam taw qhia:

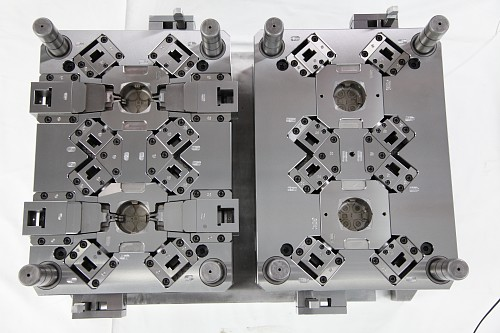

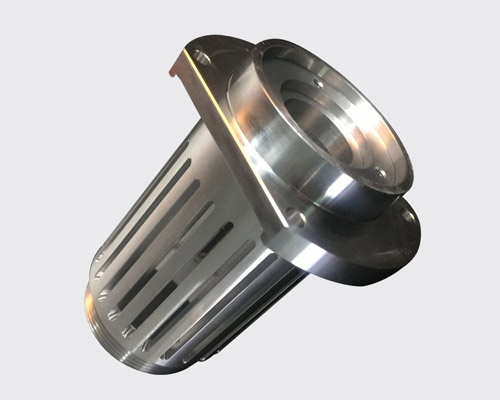

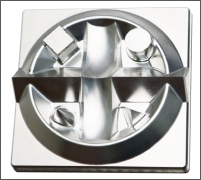

Pwm, ntau yam pwm, thiab cov cuab yeej siv hauv kev tsim khoom kom tau txais cov khoom xav tau los ntawm kev txhaj tshuaj molding, tshuab moulding, extrusion, tuag-casting lossis forging molding, smelting, stamping, thiab lwm yam.Hauv luv luv, pwm yog ib qho cuab yeej siv los ua cov khoom pwm.Cov cuab yeej no yog tsim los ntawm ntau qhov chaw, thiab cov pwm sib txawv yog tsim los ntawm cov khoom sib txawv.Nws tsuas yog paub txog kev ua tiav ntawm cov duab ntawm tsab xov xwm los ntawm kev hloov pauv ntawm lub cev ntawm cov khoom tsim.

Pwm

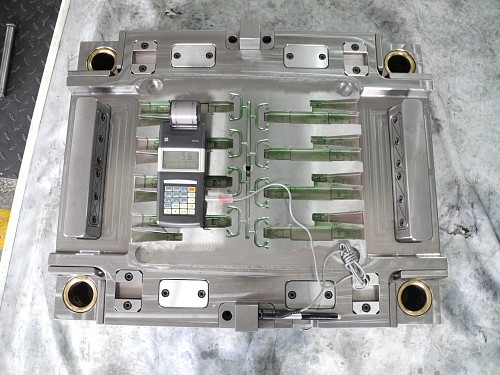

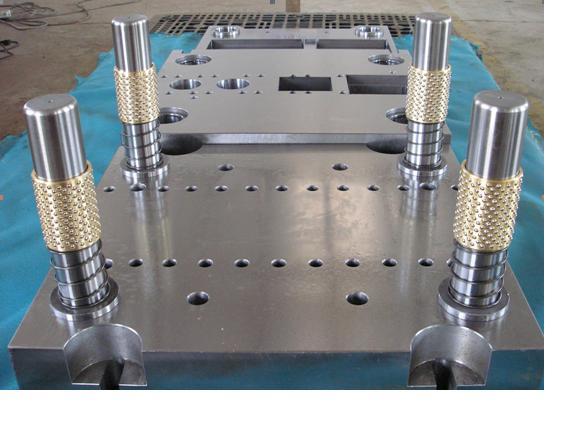

2.Lub thawv zoo li qhov chaw

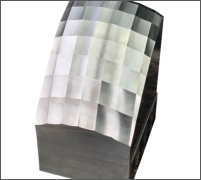

Qhov chaw nrog cov duab tsis yooj yim, kab noj hniav sab hauv, lub ntim loj thiab ntau tshaj ib lub qhov system, thiab ib qho kev faib ua feem ntawm qhov ntev, qhov dav, thiab qhov siab ntawm cov kab noj hniav yog tsim rauCNC machiningntawm machining chaw.

Box-shaped qhov chaw

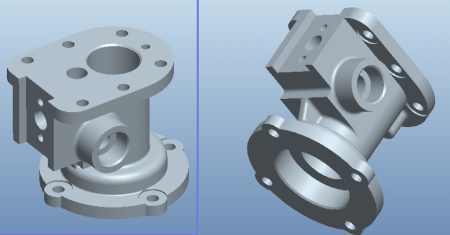

3. complex nto

CNC machining chaw tuaj yeem clamped ntawm ib zaug kom ua tiav cov txheej txheem ntawm txhua sab thiab sab saum toj tsuas yog rau qhov clamping nto.Lub hauv paus ntsiab lus ntawm kev ua yog txawv rau cov qauv sib txawv.Lub spindle lossis worktable tuaj yeem ua tiav 90 ° kev sib hloov nrog lub workpiece.Yog li ntawd, lub chaw machining yog tsim rau kev ua cov xov tooj ntawm tes, qhov chaw pib, thiab cov khoom siv aerospace.Xws li lub nraub qaum ntawm lub xov tooj ntawm tes, cov duab ntawm lub cav thiab lwm yam.

Aerospace qhov chaw

Auto qhov chaw

Kev kub ceev CNC Milling Tshuab

Pob Screw & Linear Guiderails

3 Axis pob ntsia hlau thiab cov kab qhia kev tsheb ciav hlau tau nruab nrog lub tshuab nruab nrab tsis siv neeg lubrication.3 Axis txais precision pob ntsia hlau.

3 Axis tsim nrog 4 ~ 6 pcs zawv zawg thaiv kom ntseeg tau tias lub zog raug thiab ruaj khov ntawm lub tshuab, txuas ntxiv lub neej kev pab cuam ntawm lub tshuab 3 Axis Txais cov menyuam cov kab qhia kev tsheb nqaj hlau, uas ua kom lub zog precision ntawm lub tshuab thiab ua rau lub tshuab ua si siab dua. nruj.

High rigidity qauv tsim

CovCNC milling tshuabcuab tamCov khoom tseem ceeb xws li tshuab txaj, nqaj thiab cov kab yog ua los ntawm qib siab MEEHANITE cam khwb cia hlau.Thiab tom qab ob peb txoj kev laus laus,

zoo tshem tawm cov kev ntxhov siab sab hauv, kom ntseeg tau tias covCNCVMCtshuabmuaj qhov raug zoo dua.

Thiab tom qab ob peb txoj kev laus, tshem tawm cov kev ntxhov siab sab hauv, kom ntseeg tau tias lub tshuab muaj qhov tseeb zoo dua.

Kev npaj ntawm cov kauj ruam qhia kev tsheb ciav hlau rau lub nqaj (qhov saum npoo ntawm lub nqaj thiab pem hauv ntej ntawm lub nqaj), ua ke nrog kev tsim ntawm

lub eeb super-wide, xyuas kom meej cov nyhuv ntawm cov spindle nrog siab precision thiab siab stability.

Tshwj xeeb Spindle Box Tsim

Qhov tshwj xeeb lub taub hau tsim ua rau lub z-axis txav ntau ruaj khov.Lub teeb yuag tsim ua rau nws txav nrawm dua horizontally thiab vertically kom ua tiav lub hom phiaj ntawm cov lus teb ceev.

Cov neeg siv kev paub zoo dua

Ib txhiantsugCNC milling tshuab tuaj yeem xaiv cov ntawv ntim tag nrho, muab cov neeg siv nrog kev nyab xeeb, ib puag ncig tus phooj ywg.Lub thawv ua haujlwm semi-rotating thiab lwm yam humanized designs muab cov neeg siv nrog kev ua haujlwm yooj yim thiab nyab xeeb.

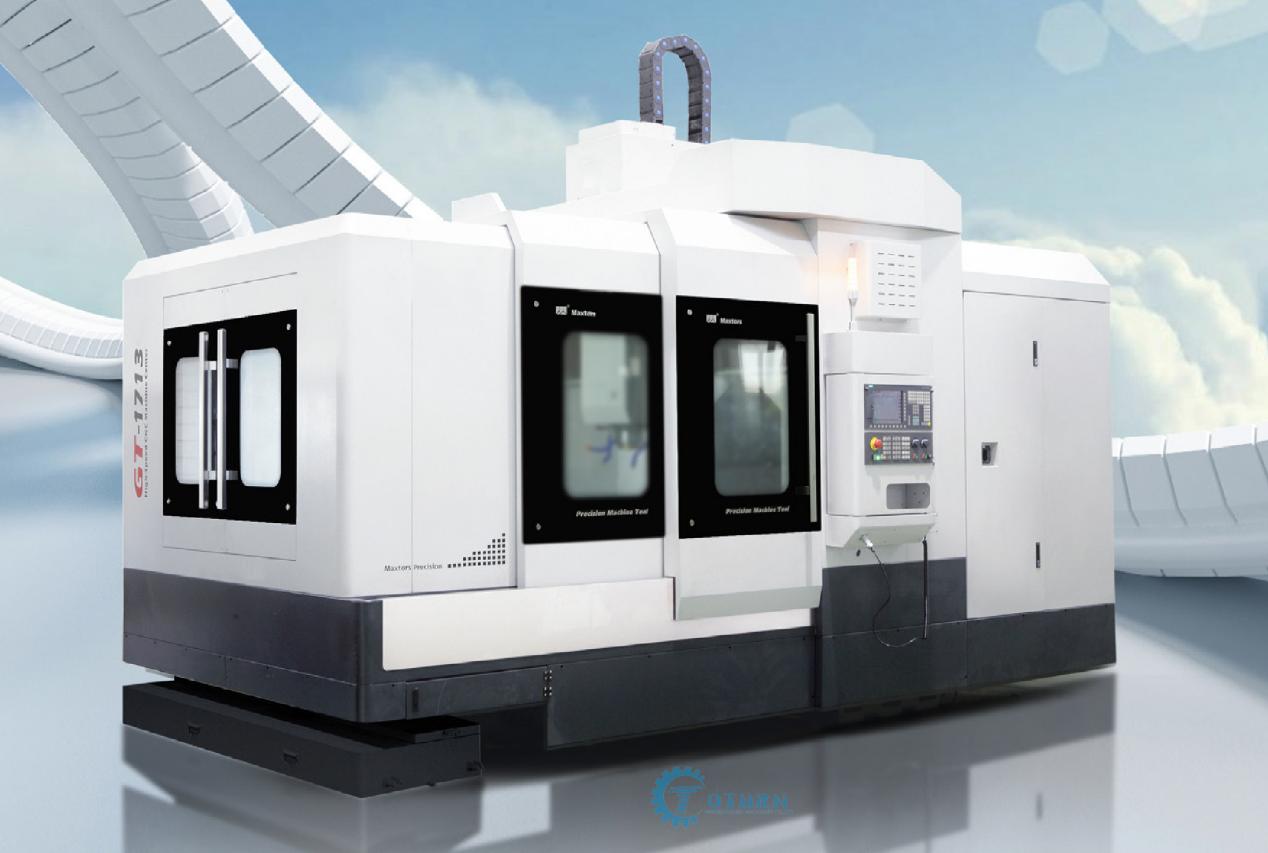

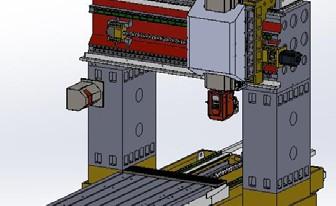

Siab ceevTshuab Center

Qhov noSiab ceevTshuab CenterUa kom muaj zog rigidity, qauv symmetry thiab zoo stability nyob rau hauv lub hauv paus ntawm tsoos gantry tshuab foundation ncej, qhia lub thoob ntiaj teb advanced dynamic rigidity tsim tswvyim thiab optimizes tus tsim ntawm lub tsiv qhov chaw.Lub tshuab no muaj zog rigidity thiab ceev teb, uas yuav ua tau raws li cov kev xav tau ntawm high-precision aviation qhov chaw ua thiab ntau yam high-precision pwm ua.

3 Axis tus qauv nrog Linear Scales, Positioning ntau dua.

Laser Tool Probe (Yeem)

Txuj nrog 21T ATC / Tool Magazine nws tuaj yeem txhim kho kev ua haujlwm zoo ntawm kev npaj machining.

3 Axis Roller Guiderails, siab precision thiab tsis tshua muaj kev sib txhuam coefficient, uas tuaj yeem txo lub tshuab

creeping phenomenon ntawm tsawg ceev, zoo positioning raug thiab siab dynamic teb yam ntxwv.

Adopts Built-in hom High Speed Motorized

Spindle, Max.20000rpm, zoo tshaj plaws rau High Precision & Zoo Nto Zoo Ua.

Ob kab thiab crossbeam yog tag nrho ib feem ua rau lub CNC Gantry Milling Tshuab muaj ib tug zoo rigidity, ntev stability thiab zoo heev poob siab absorbing kev kawm.Nruab nrog cov tswj kev ua haujlwm siab, servo lub cev muaj zog, siab precision qhia txoj kev / ntsia hlau ua rau nws ua haujlwm siab thiab ua haujlwm siab.CNC Gantry Milling Tshuab.Z axis yog nruab nrog nitrogen booster clinder kom txo tau lub nra ntawm lub cev muaj zog.Yog li ntawd covCNC Gantry Milling Tshuabtuaj yeem tsom rau lub peev xwm milling.HSK high-speed spindle yog xaiv tau uas tuaj yeem txhim kho qhov kev ua haujlwm ntawm milling.Kev tswj xyuas kev tshawb fawb thiab cov cuab yeej tshawb nrhiav nruj kom paub meej thiab zoo ntawm lub tshuab.CNC maub los zoo li Siemens, Fanuc lossis Mitsubishi tuaj yeem xaiv kom tau raws li cov neeg siv khoom siv.

Qhov no CNC Gantry Milling Tshuabyog dav siv nyob rau hauv pib-qhov chaw, aerospace, pwm, cav, khoom siv hauv tsev thiab lwm yam.

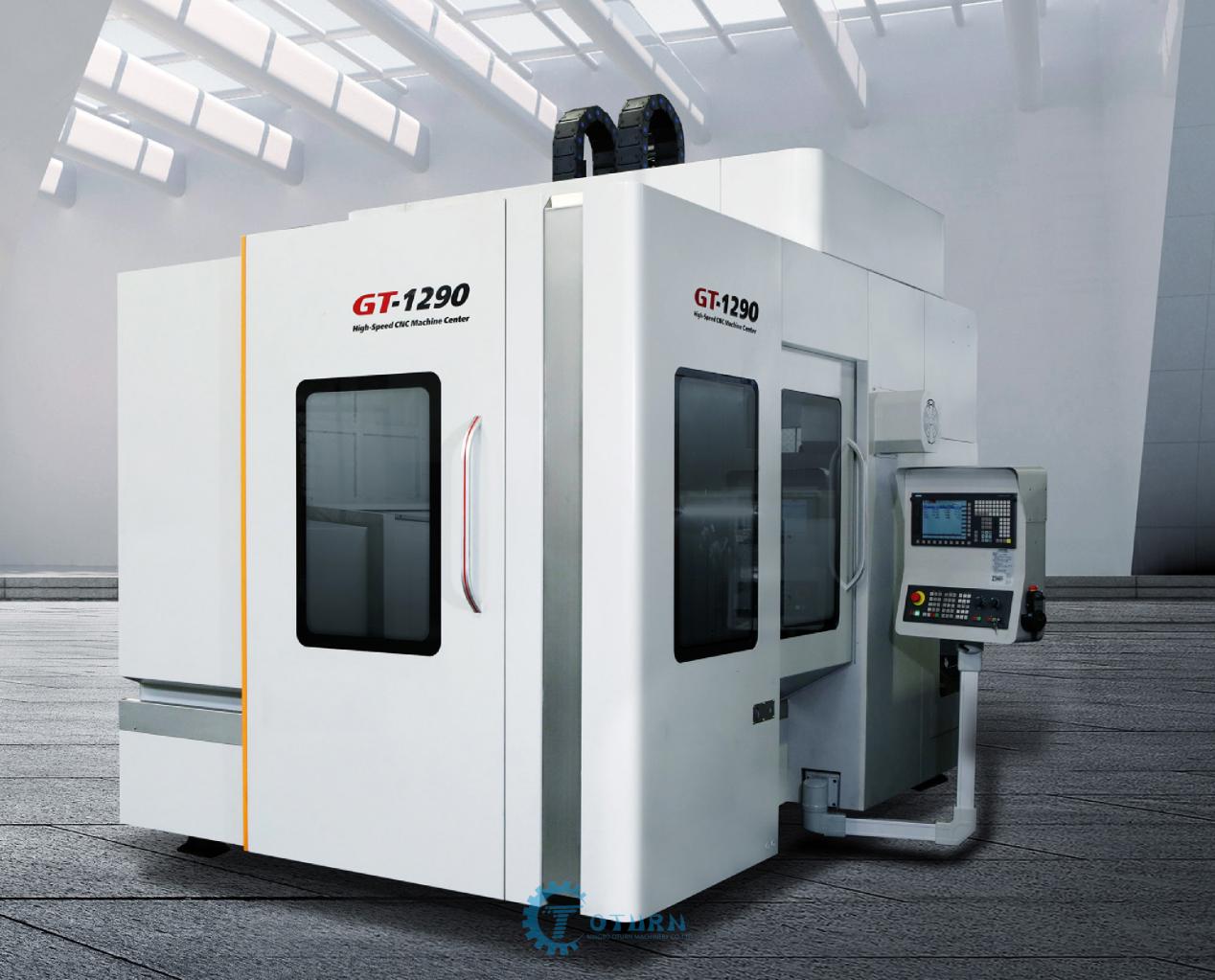

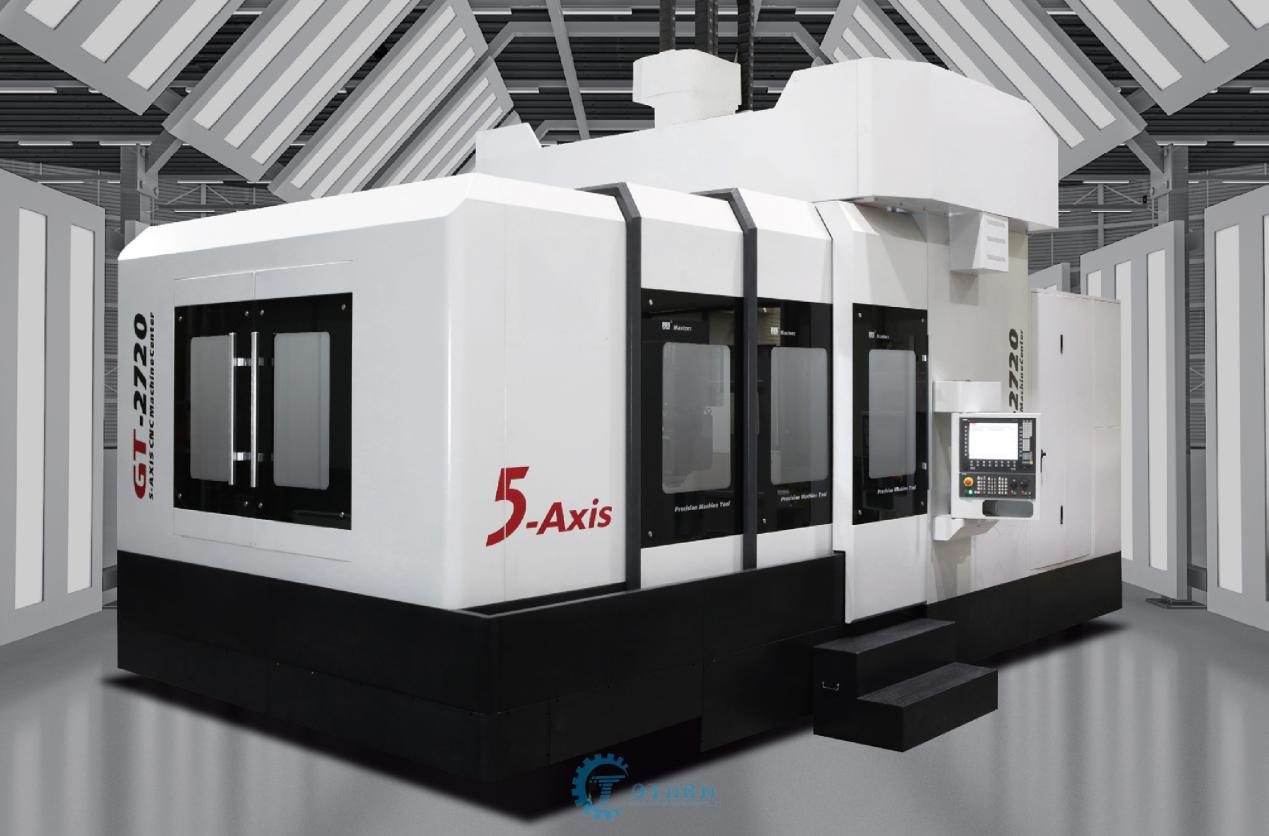

Ob Chav Kem Hom5 Axis Tshuab Center

Lub tshuab no yog Ob Chav Kem Hom 5 Axis Tshuab CenterUa kom muaj zog rigidity, qauv symmetry thiab zoo stability nyob rau hauv lub hauv paus ntawm tsoos gantry tshuab foundation ncej, qhia lub thoob ntiaj teb advanced dynamic rigidity tsim lub tswv yim thiab optimizes tus tsim ntawm lub tsiv qhov chaw.Lub tshuab no muaj zog rigidity thiab ceev teb, uas yuav ua tau raws li. cov kev xav tau ntawm high-precision aviation qhov chaw ua thiab ntau yam high-precision pwm ua.

Qhov kev ncua deb ntawm Spindle Center rau kev taw qhia kev tsheb nqaj hlau yog luv.with Zoo Cov Txheej Txheem Rigidity Beam, txhim khu kev ruaj ntseg ntawm spindle.Z - axis nrog 4 daim guderails tsim qauv, Tag nrho cov qauv rigidity ho txhim kho.

Txais yuav high-speed Built-in spindle, max 20000RPM, uas tuaj yeem muab kev daws teeb meem zoo tshaj plaws rau kev ua haujlwm siab thiab ua haujlwm siab zoo.

3 Axis tus qauv nrog Linear Scales, Positioning ntau dua.

Covntsug thiab kab rov tavCNC machining chawyog qhov txuas tseem ceeb heev hauv cov txheej txheem ntawm kev lag luam tag nrho.Nyob rau hauv xyoo tas los no, cov neeg siv khoom hauv kev lag luam thoob ntiaj teb tau hloov lawv txoj kev xav ntawm Tuam Tshoj lub tshuab machining chaw.Cov theem sib dhos, qhov tseeb thiab ruaj khov ntawm qhov chaw machining, thiab cov qauv tsim tau zoo heev, thiab nws twb muab piv rau Taiwan, Nyiv thiab South Kauslim hom.Ua ke nrog Tuam Tshoj cov khoom lag luam tshwj xeeb, kev tsim khoom thiab cov nqi tsim khoom yog qis dua li ntawm Taiwan, Nyiv thiab Kaus Lim Qab Teb, ua rau cov khoom lag luam tsim khoom thiab cov nqi tsim khoom yog qis dua li ntawm Taiwan, Nyiv thiab Kaus Lim Qab Teb.chaw ua haujlwmtau lees paub los ntawm cov neeg siv khoom hauv European thiab Asmeskas kev lag luam txhua xyoo, uas tseem qhia txog kev txhim kho ntawm Tuam Tshoj txoj kev lag luam muaj zog.

Txawm li cas los xij, peb tseem muaj qhov sib txawv ntawm pebsiab dua-precision CNC machining chawthiab cov tshuab hauv European thiab Asmeskas kev lag luam, thiab txawm tias qee qhov ntawm peb cov khoom siv tseem ceeb thiab cov thev naus laus zis tseem yuav tsum tau xa tuaj.Covmachining chawntawm qee lub tebchaws tsim tau twb tau ua tiav high-precision, high-speed, composite multi-function, multi-axis linkage thiab lwm yam haujlwm.Cov no yog cov cheeb tsam uas tseem muaj qhov sib txawv ntawm Tuam Tshoj thiab cov teb chaws tsim nyob hauv Europe thiab Tebchaws Meskas.Txoj kev loj hlob ntawm Tuam Tshoj lub tsib-axis tsib-txuas machining chaw yog tseem txwv los ntawm txawv teb chaws cov lej tswj systems, yog li cov kev ua tau zoo thiab kev kawm theem ntawm ib co high-tech khoom tsis tau raws li qhov yuav tsum tau, uas ua rau ib co khoom thiab core Cheebtsam yuav tsum tau cia siab rau imports. .Yog li ntawd, peb tau pom tias ib txhiaTuam Tshoj CNC machining chaw tsim khoomcov nroj tsuag yog nyob rau hauv thiaj li yuav tau txais ntau qhov chaw ua lag luam nyob rau hauv lub thoob ntiaj teb theem, thiab lawv kuj tau nce mus ua ib co kev hloov.Qhov no yog lub hom phiaj ntawm cov neeg Suav tiam.

Tam sim no, peb cov neeg siv khoom muaj xws li nkoj tsim, kev lag luam textile, tsheb tsim, kev lag luam aerospace, thiab lwm yam. Cov neeg siv khoom no muaj cov kev xav tau siab rau kev ua haujlwm ceev, kev raug thiab ntau lawm ntawm cov cuab yeej siv tshuab.Muaj cov kev cai nruj dua ntawm kev teeb tsa ntawm spindle.Piv txwv li, lub spindle ceev yuav tsum siab tshaj 12000rpm / min, thiab qhov txav ceev yog siab tshaj 40m / min.Rau complex workpieces, tshwj xeeb tshaj yog nkhaus nto nrog complex duab, lawv muaj siab heev yuav tsum tau rau qhov tseeb thiab efficiency.Multi-axis machining yuav tsum yog qhov kev xaiv, xws li me me 5-axis 5-linkage machining centers thiab loj5-axis gantry machining chaw.

Nrog rau kev maj mam ua tiav ntawm kev lag luam automation, machining chaw thiab kev lag luam robots tau siv ua ke, tso cai rau cov neeg hlau dais qee qhov yooj yim thiab rov ua haujlwm, uas tuaj yeem txuag tau ntau tus nqi tsim khoom.Ua ke nrog kev ruaj ntseg ntawm cov neeg hlau thiab lub chaw machining, qhov zoo ntawm cov khoom kuj tau lav.

Xyoo no txoj kev loj hlob ntawm machining chaw yog cuam tshuam loj heev los ntawm qhov tsis muaj peev xwm muab CNC tshuab raws sijhawm.Tam sim no, CNC tshuab nruab rau hauv Suav machining chaw yog yuav luag txhua hom txawv teb chaws, xws li FANUC, MITSUBISHI, SIEMENS.Thiab kuv lub teb chaws Taiwanese hom Syntec, LNC domestic hom GSK, KDN Txawm hais tias Huadong CNC thiab lwm yam tuaj yeem paub txog cov haujlwm ntawm cov npe nrov txawv teb chaws, tseem muaj qee qhov tsis muaj peev xwm hloov tau.

Raws li kev koom ua ke ntawm industrial innovation teb thiab technology,chaw ua haujlwmkuj yog lub teb chaws txoj kev loj hlob theem.Raws li Tuam Tshoj tau dhau los ua qhov tseem ceeb tshaj plaws nyob rau theem thoob ntiaj teb, Suav cov neeg hlau yuav tsum tau ua haujlwm ua ke los txhim kho Tuam Tshoj tag nrho qib.

Post lub sij hawm: Sep-18-2021