CNC tig-milling ua ke tshuab

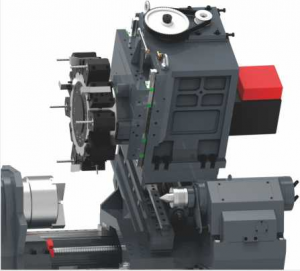

INTEGRATED POSITIVEYAXIS

Longmen qauv, super nruj

Integrated zoo Y axis qauv belongs rau high-rigidity hnyav txiav thiab nws cov kev ua tau zoo yog zoo dua li cov interpolation Y axis.

ib. Ib qho Y axis txav hnyav txiav yog zoo dua li kev cuam tshuam Y axis thiab Y axis yog perpendicular rau X axis.

b. Lub dav hlau contour ua yog smoother thiab flatter.

c. Yooj yim dua rau kev sib xyaw nto thiab contour ua.

"Zoo Y" tig-milling ua ke cov cuab yeej muaj txiaj ntsig zoo hauv machining dav hlau milling piv nrog "interpolation Y" tig-milling ua ke.Qhov kev txav ntawm "Zoo Y" Y-axis yog perpendicular rau X-axis, uas yog ib leeg. -axis txav thiab "interpolation Y" Y-axis txav yog los cuam tshuam txoj kab ncaj nraim los ntawm kev txav ib txhij ntawm X-axis thiab Y-axis, qhov flatness ntawm qhov milling dav hlau thiab kev sib piv ntawm "zoo Y" axis tig-milling ua ke, "Zoo Y" axis tig-milling ua ke ua ke yog pom tseeb ci thiab tiaj tus.

Ob chav tsau pob ntsia hlau

High-quality pob screws thiab cov menyuam cov lus qhia los ntawm cov tuam txhab thoob ntiaj teb sab saum toj yog siv.

Txawm hais tias kim, tsuas yog cov khoom zoo tuaj yeem ua tau raws li qhov siab precision thiab ntev

kev pabcuam lub neej xav tau los ntawm cov neeg siv khoom.

Direct-Coulled Servomotors

Lub servo lub cev muaj zog txuas ncaj qha mus rau lub pob ntsia hlau los ntawm cov hlau txuas, uas

xyuas kom tsis muaj degeneration thiab misalignment txawm nyob rau hauv hnyav loads.

Qhov no yuav zoo heev txhim kho qhov tseeb, thiab xov thiab contour machining

yuav muaj tseeb dua.

106M 108M 208M

| lwm Model | Lub npe | Chav tsev | 106 MAS | 108 MAS | 208 MAS |

| Mus ncig | Max. Txoj kab uas hla ntawm lub txaj | mm | φ600 | φ600 | φ600 |

| Max. Txoj kab uas hla | mm | Ib φ320 | φ300 | φ400 | |

| Max. Txoj kab uas hla ntawm lub Tool Holder | mm | φ220 | φ220 | Ib φ380 | |

| Max. Ua Ntev | mm | 250 | 250 | 370 | |

| Qhov nrug nruab nrab ntawm qhov chaw | mm | 380 | 380 | 600 | |

| Spindle Tsav Hydrocylinder Chuch Parameter | Spindle Nose | hom | A2-5 | A2-6 | A2-6 |

| Max. Ceev ntawm Spindle | rpm ua | 5500 | 4300 ib | 4 200 | |

| Roj Lub tog raj kheej / Chuck | lnch | 6” | 8 " | 8 " | |

| Spindle Bore | mm | ib φ56 | φ65 ib | φ65 ib | |

| Bar Diameter | mm | φ45 | ib φ52 | ib φ52 | |

| Direct Drive Spindle Tsav Fais Fab | kw | 17.5 Nws | 22 | 22 | |

| X/Z/Y Axis Pub Parameter | X Taug kev | mm | 180 | 180 | 280 |

| X/Z Linear Guide Specification | spes | 35 / 35 Rolller | 35 / 35 Rolller | 35 / 35 Rolller | |

| Z ncig teb chaws | mm | - | 300 | 600 | |

| X / Z / Y lub cev muaj zog | kw | 1.8/1.8/1.0 | 1.8/1.8/1.0 | 1.8/1.8/1.0 | |

| X/Z//Y Rapid Traverse | m/min | 30/30/10 | 30/30/10 | 20/20/10 | |

| Positioning raug | mm | ± 0.005 | ± 0.005 | ± 0.005 | |

| Rov ua qhov tseeb qhov tseeb | mm | ± 0.003 | ± 0.003 | ± 0.003 | |

| Turret Parameter | Tool txoj hauj lwm | pcs | BMT45-12T | BMT45-12T | BMT55-12T |

| Lub cev muaj zog Turret | kw | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | |

| Square Tool Holder | mm | 20 × 20 | 20 × 20 | 20 × 20 | |

| Round Boring Tool Holder | mm | Ib φ32 | Ib φ32 | φ40 | |

| Lub Sijhawm Sib Txuas Hloov Sijhawm | sec | 0.15 | 0.15 | 0.15 | |

| Positioning raug | / | ± 2 " | ± 2 " | ± 2 " | |

| Rov ua qhov tseeb qhov tseeb | / | ± 1 " | ± 1 " | ± 1 " | |

| Tailstock Tsis muaj | Programmable Hydraulic Tailstock | / | √ | √ | |

| Max. Taug kev ntawm Tailstock | mm | 360 | 360 | 440 | |

| Tailstock Tes Tsho Taper Qhov | hom | MT 5 # | MT 5 # | MT 5 # | |

| Lub tes tsho Dia | mm | / | / | / | |

| Tes Tsho Mus Ncig | mm | / | / | / | |

| Mechanical Size | Tshuab Loj | mm | 2300 × 1800 × 1700 hli | 2300 × 1800 × 1700 hli | 2620 × 2200 × 1920 hli |

| Tshuab hnyav | kg | 3 700kg | 3800kg ib | 5200kg ib |

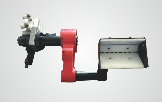

Servo Tsis Siv Neeg Bar Feeder

TENOLY feeders muaj lub luag haujlwm hnyav thiab tsis siv neeg tsim,

Nws ua kom muaj txiaj ntsig zoo thiab ua kom yooj yim txoj haujlwm tig.

Parts Catcher

Lub workpiece catcher yog tsim los nrog lub hauv paus ntsiab lus ntawm kev sib txuas ntawm kev sib txuas, uas tuaj yeem ua tau sai

txuas nrog cov khoom tiav tom qab ua tiav.

THK roller linear phau ntawv qhia

Daim ntawv qhia linear muaj xoom clearance, arc txiav, bevel txiav, thiab nto kev ntxhib los mos kuj zoo ib yam. Nws yog qhov tsim nyog rau kev ua haujlwm siab ceev thiab txo cov tsav tsheb horsepower uas yuav tsum tau rau lub tshuab Linear qhia rails siv dov es tsis txhob zawv zawg, nrog kev sib txhuam me me, cov lus teb rhiab thiab qhov chaw siab. Nws muaj peev xwm dais lub load in the up, down, left and right directions tib lub sij hawm. Nyob rau hauv lub load, qhov kev sib cuag ntawm tus khiav yog tseem nyob rau hauv multi-point contact, thiab txiav rigidity yuav tsis raug txo; Yooj yim thiab sib hloov sib dhos thiab yooj yim lubricating qauv; cov linear guides muaj tsawg heev hnav thiab kav ntev.

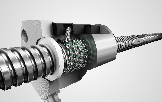

THK Pob Ntsia Hlau

Siv high-precision pob ntsia hlau, nrog txiv ntseej preloading thiab ntsia hlau

pretensioning kev kho mob, lub backlash thiab kub nce thiab

elongation raug tshem tawm ua ntej, qhia qhov chaw zoo heev

thiab repeatability.

Direct tsav nrog servo lub cev muaj zog kom txo qis backlash yuam kev.

High Precision Motorized caj npab rau tshuab dhos

Pull-down cuab tam setter nrog siab precision repeatability Muaj nyob rau hauv ntau qhov sib txawv qhov ntau thiab tsawg kom tau raws li ntau yam kev xav tau Muaj nyob hauv ntau qhov ntau thiab tsawg, nrog rau kev cai-ua steel ntsuas caj npab nrog tsawg coefficient ntawm expansion

Siv lub zog zirconia sojntsuam

Siv lub tshuab me me thaum tsis siv

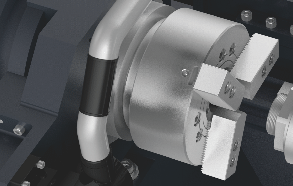

Hydraulic Chuck Ua Haujlwm

Lub tshuab dhos yog nruab nrog hydraulic los ntawm qhov chuck raws li tus qauv. Lub chuck tuaj yeem hloov kho raws li cov neeg siv khoom xav tau, thiab ntau yam kev xaiv yuav muab rau koj qhov haum tshaj plaws clamping chuck.

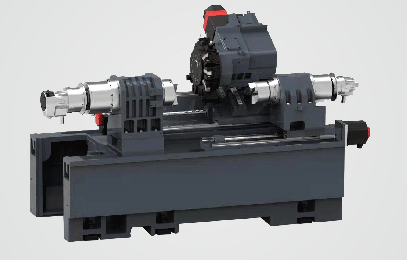

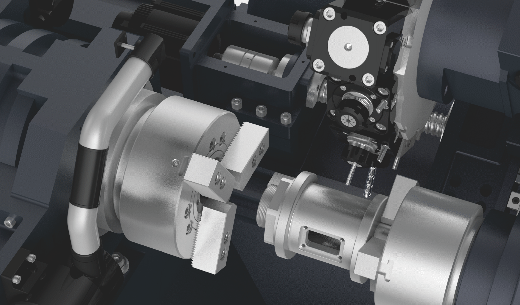

Secondary Spindle

Ob qhov kawg ntawm lub workpiece tuaj yeem ua tiav tib lub sijhawm hauv ib lub clamping, uas yooj yim heev rau kev siv phau ntawv.