Nyob rau hauv xyoo tas los no, kev lag luam xav tau maj mam hloov los ntawm cov khoom ib txwm siv rau cov khoom lag luam nrog cov yam ntxwv ntawm kev tswj tus lej, kev txawj ntse thiab kev cog qoob loo.

1. Drilling tshuabcov khoom lag luam xwm txheej

Tam sim no, cov neeg siv cov kev xav tau rau cov khoom siv drilling tshuab qhia ntau theem.Qee cov neeg siv khoom siv tshwj xeeb los hloov cov cuab yeej siv dav dav, thiab qee cov neeg siv xaiv cov khoom lag luam nrog cov nqi qis dua.Txawm li cas los xij, tag nrho cov kev xav tau ntawm cov neeg siv pawg rau cov khoom siv tshuab drilling yog qhov zoo automation, kev tswj tus lej, kev ua haujlwm siab, loj loj thiab lwm yam.

Los ntawm kev xav ntawm Asia tam sim no kev lag luam kev lag luam xav tau muaj peev xwm, me meCNC drilling thiab milling tshuabcia siab tias yuav ua kom muaj kev ruaj ntseg thiab kev loj hlob sai rau lub sijhawm ntev.CNC drilling thiab milling tshuab tau dhau los ua thawj qhov kev xaiv rau drilling thiab ua cov khoom ntxeem tau xws li tsheb, locomotives, nkoj, aerospace, siv tshuab thiab lwm yam lag luam, tshwj xeeb tshaj yog rau cov laminates ntev ntev, cov kab ntev ntev, cov qauv hlau, thiab tubular qhov chaw. .

2. Kev ua lag luam xwm txheej ntawmtshuab tho txawvcov khoom

Nyob rau hauv xyoo tas los no, thev naus laus zis ntawm kab rov tav tho txawv thiab milling tshuab thiab hauv pem teb milling thiab tho txawv tshuab hauv tsev thiab txawv teb chaws tau tsim sai heev, uas yog tus cwj pwm los ntawm kev hloov kho tshiab ntawm cov khoom tsim, kev siv tsis kawg ntawm cov thev naus laus zis tshiab, kev sib sib zog nqus ntawm cov degree. ntawm kev sib xyaw txheej txheem kev ua tau zoo, kev txhim kho txuas ntxiv ntawm kev ceev thiab kev ua haujlwm, thiab qhov tseem ceeb ntawm kev tsim khoom zoo.Hauv cov cheeb tsam tseem ceeb hauv qab no, cov khoom siv tshuab tho txawv muaj cov ntawv thov tseem ceeb:

fuselage (nrog rau lub qhov ntswg, tis, tus Tsov tus tw, thiab lwm yam) ua.Cov khoom no feem ntau yog cov qauv loj, thiab cov khoom siv feem ntau yog aluminium alloys, titanium alloys, thiab lwm yam.CNC pem teb milling thiab tho txawv tshuab, thiab tseem suav nrog CNC gantry tho txawv thiab tshuab milling, CNC gantry machining chaw, thiabCNC tsib-axis txuas gantry machining chaw.

Machining ntawm aircraft tsaws iav.Cov ntaub ntawv xav tau rau lub dav hlau tsaws iav yog qhov tshwj xeeb.Kev tsaws bracket yog ua los ntawm high-strength titanium alloy thiab lwm yam ntaub ntawv, uas yog nyuaj rau txheej txheem.Qhov khoob yuav tsum tau forged los ntawm 10,000-tuj xovxwm, thiab machining yuav tsum tau CNC pem teb milling thiab tho txawv tshuab, gantry tsib-axis txuas machining chaw thiab lwm yam khoom siv..

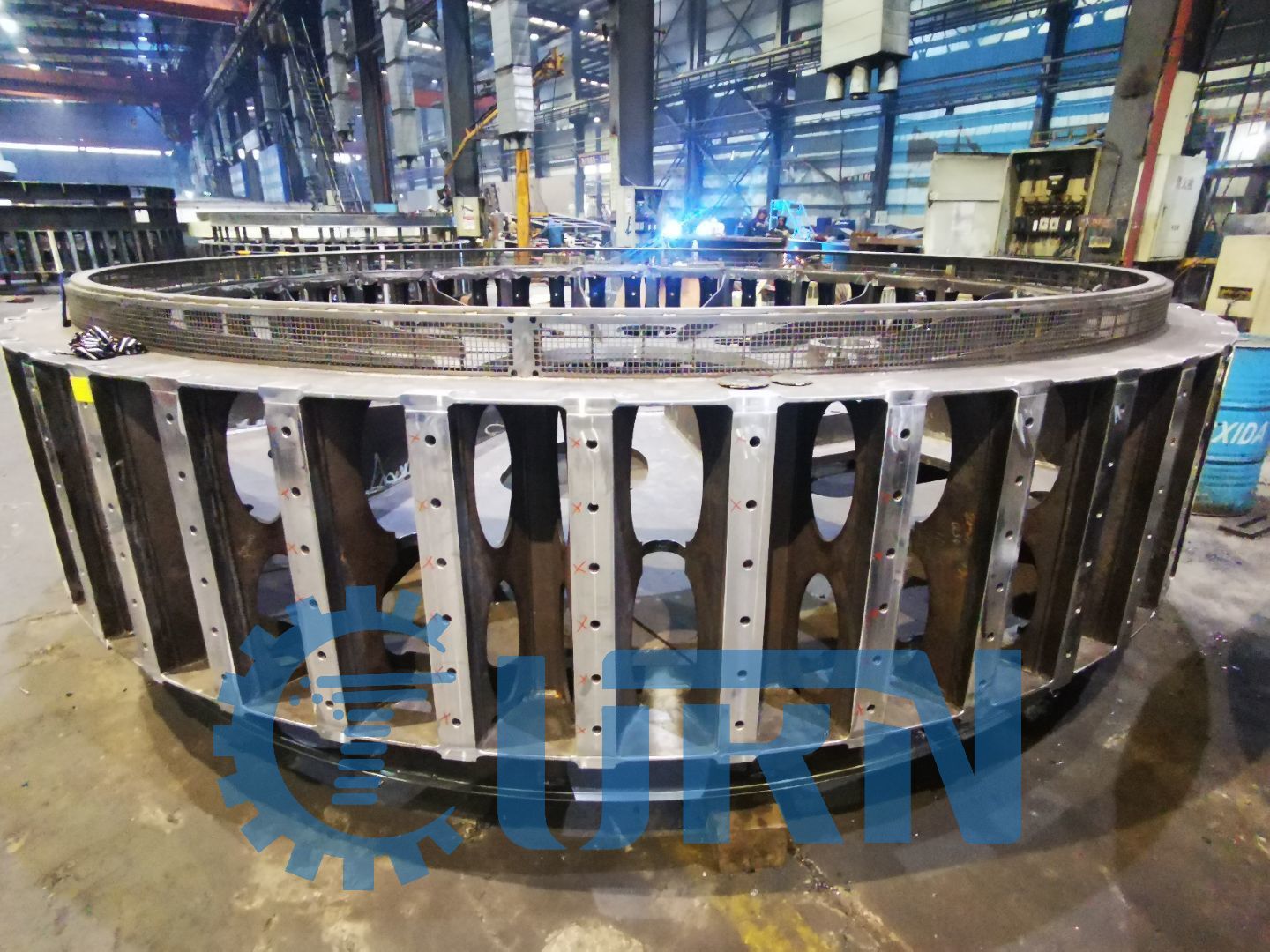

Tsis tas li ntawd, cov cuab yeej tsim hluav taws xob tsim kev lag luam xav tau cov cuab yeej loj hauv pem teb tho txawv thiab milling tshuab, hnyav CNC gantry tho txawv thiab milling tshuab, CNC lathes loj, tshwj xeeb milling tshuab rau cov hniav hauv paus grooves thiab hniav CNC machining tshuab;lub zog kis tau tus mob thiab hloov khoom siv kev lag luam kev lag luam yuav tsum tau CNC lathes, machining chaw,CNC tho txawv tshuab, lwm..

Post lub sij hawm: May-26-2022