Tshiab zam tsim rau Tuam Tshoj Hoobkas kub muag Aluminium Machining Center rau Aluminium Profile

Peb vam khom raws li kev xav, kev hloov kho tshiab tsis tu ncua hauv txhua ntu, kev nce qib thev naus laus zis thiab tau kawg ntawm peb cov neeg ua haujlwm uas koom ncaj qha rau hauv peb txoj kev vam meej rau Kev Tsim Qauv Tshiab rau Tuam Tshoj Hoobkas Kub Muag Aluminium Machining Center for Aluminium Profile, Peb tos ntsoov muab koj nrog peb. cov khoom thaum nyob rau hauv ze ze rau lub sij hawm ntev, thiab koj yuav nrhiav tau peb cov lus hais yog tsis tshua muaj tseeb raws li zoo raws li high-zoo ntawm peb cov kev daws teeb meem yog incredibly zoo heev!

Peb vam khom raws li kev xav, kev hloov kho tshiab tsis tu ncua hauv txhua ntu, kev nce qib thev naus laus zis thiab tau kawg ntawm peb cov neeg ua haujlwm uas koom ncaj qha rau hauv peb txoj kev vam meej.Tuam Tshoj CNC Machining Center, Raws li ib txoj hauv kev siv cov peev txheej ntawm cov ntaub ntawv nthuav dav hauv kev lag luam thoob ntiaj teb, peb zoo siab tos txais cov kev cia siab los ntawm txhua qhov chaw ntawm lub vev xaib thiab offline. Txawm hais tias muaj cov khoom zoo uas peb muab, kev pabcuam kev sib tham zoo thiab txaus siab yog muab los ntawm peb pab pawg pabcuam tomqab muag. Cov npe khoom thiab cov ncauj lus kom ntxaws thiab lwm yam ntaub ntawv weil raug xa tuaj rau koj raws sijhawm rau cov lus nug. Yog li thov hu rau peb los ntawm kev xa email rau peb lossis hu rau peb thaum koj muaj lus nug txog peb lub koom haum. koj tseem tuaj yeem tau txais peb qhov chaw nyob cov ntaub ntawv los ntawm peb lub xaib thiab tuaj rau peb lub lag luam. Peb tau txais ib daim ntawv ntsuam xyuas ntawm peb cov khoom. Peb cia siab tias peb yuav sib koom ua ke ua tiav thiab tsim kom muaj kev sib raug zoo nrog peb cov phooj ywg nyob rau hauv qhov chaw ua lag luam no. Peb tab tom nrhiav rau pem hauv ntej rau koj cov lus nug.

Tshuab Nta

OTURN machining chaw yog ua los ntawm qhov zoo tshaj plaws zoo Mihanna cam khwb cia hlau lub cev thiab tag nrho rib txhawb, uas yog kaum npaug ntau poob siab-absorbing tshaj li qub hlau hlau. Cov castings nrog tav nyob rau sab hauv ntawm lub fuselage muaj siab torsion tsis kam thiab super shock resistance. Tsis tas li ntawd, qhov dav hauv qhov chaw tso cai rau tus neeg teb xov tooj hloov cov cuab yeej thiab cov khoom ua haujlwm tau yooj yim. Nrog rau cov qauv rigidity siab, nws tsim cov hneev taw me me, tab sis high-precision thiab multi-bacterial automatic machinery.

Ou Teng siv cov npe nrov ntawm kev ua haujlwm siab thiab kev ua haujlwm zoo ntawm cov kab swb. Nws cov txheej txheem thev naus laus zis zoo li kev tsim cov kabmob, nrog xoom tshem tawm thiab txhua yam kabmob kabmob. Lub linear swb muaj tsawg noj, siab precision, thiab ceev txav ceev, mus txog 48 meters ib feeb.

Lub tshuab yog nruab nrog high-brightness ua hauj lwm teeb, uas yog yooj yim rau tus neeg teb xov tooj thauj thiab unload workpieces thiab ua kev ntsuas. Lub teeb ua haujlwm muaj kev ua haujlwm ntawm plua plav, tsis muaj dej thiab tawg-pov thawj.

Cov cuab yeej ceev, yooj yim, txhim khu kev qha thiab lub neej ntev kev sib pauv khoom muab kev sib pauv cov cuab yeej du thiab txhim khu kev qha. Cov cuab yeej tshwj xeeb sib pauv khoom tsim, muaj peev xwm xaiv cov cuab yeej ntawm txhua txoj haujlwm, tuaj yeem ncav cuag sai los ntawm PLC software tswj.

Specification

| Yam khoom | Chav tsev | v850 ua | v 1160 | v 1370 | v1580 ua |

| Machining ntau yam | |||||

| X axis taug kev | mm | 800 | 1100 | 1300 | 1500 |

| Y axis taug kev | mm | 550 | 600 | 700 | 800 |

| Z axis taug kev | mm | 550 | 600 | 700 | 700 |

| Kev ncua deb ntawm lub qhov ntswg ntawm spindle mus rau lub rooj ua haujlwm | mm | 120-670 : kuv | 120-720 : kuv | 120-820 : kuv | |

| Kev ncua deb ntawm qhov chaw ntawm lub spindle mus rau qhov chaw khiav ntawm kab | mm | 595 ib | 650 | 750 | 865 ib |

| Lub rooj ua haujlwm | |||||

| Rooj loj | mm | 1000 × 550 | 1200 × 600 hli | 1400 × 700 hli | 1600 × 800 hli |

| Max load ntawm workbench | kg | 500 | 800 | ||

| T-qhov | mm | 5 x18x90 | 5 x 18 x 100 | 7 x 22 x 110 | 7 x 22 x 100 |

| Spindle | |||||

| Spindle ceev | rpm ua | 8000 | 6000 | ||

| Spindle torque | Nm | 35/47, 7 | 47/70 ib | 140/190 ib | |

| Spindle taper | BT-40 | BT-50 | |||

| Spindle zog | KW | 7.5 | 11 | 15 | |

| Lwm yam | |||||

| Qhov ntev | mm | 2600x2500x2700 | 3200x2700x3000 | 4180x3050x3187 | 4580x3050x3187 |

| Tshuab hnyav | T | 5 | 6.5 | 10 | 15.5 ib |

Nthuav dav Configuration

Muab ob npaug rau kauv nti tshem tawm

Muab ob npaug rau kauv nti tshem tawm cov cuab yeej, xuas nrig ntaus rau lub kauv nti tshem tawm tshuab ntawm ob sab ntawm lub tshuab, tuaj yeem yooj yim xa cov txheej txheem hlau mus rau sab nraud ntawm lub tshuab sai, txo cov khib nyiab ntawm lub sijhawm tsis ua haujlwm vim kev tshem tawm cov hlau chips. .

Txhua lub tshuab siv laser ntsuas, txiav kev xeem, kev ua haujlwm ntev-hauv kev sim thiab kev tshuaj xyuas nruj raws li VDI 3441 tus qauv, kom txhua lub axis muaj qhov rov ua tau zoo thiab qhov chaw raug, ua kom lub tshuab raug.

Lub voj voog ntsuas ntsuas Renishaw yog siv los kho qhov roundness thiab geometric raug ntawm lub tshuab, yog li xyuas thiab xyuas kom meej qhov tseeb ntawm qhov chaw peb sab.

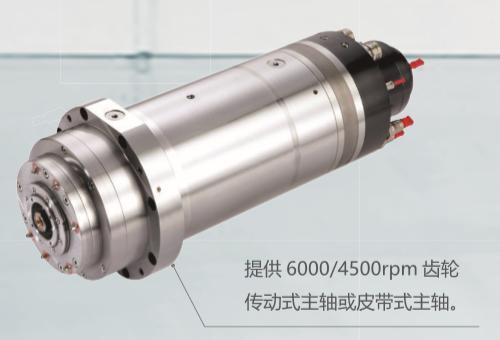

Lub tes tsho-hom spindle tsim muab 6000/4500rpm iav-tsav spindle los yog siv-hom spindle, thiab luv-nosed spindle bearing tau txais txiaj ntsig zoo los ntawm lub tes tsho thiab lub taub hau casting, yog li nws tuaj yeem txhim kho qhov rigidity ntawm spindle. Lub tshuab spindle tuaj yeem tso saib qhov siab tshaj plaws hlau txiav tus nqi. Nrog rau spindle txias system, qhov kub nce ntawm cov kabmob tuaj yeem txo kom ntev lub neej ntawm spindle.

Workpiece

Peb vam khom raws li kev xav, kev hloov kho tshiab tsis tu ncua hauv txhua ntu, kev nce qib thev naus laus zis thiab tau kawg ntawm peb cov neeg ua haujlwm uas koom ncaj qha rau hauv peb txoj kev vam meej rau Kev Tsim Qauv Tshiab rau Tuam Tshoj Hoobkas Kub Muag Aluminium Machining Center for Aluminium Profile, Peb tos ntsoov muab koj nrog peb. cov khoom thaum nyob rau hauv ze ze rau lub sij hawm ntev, thiab koj yuav nrhiav tau peb cov lus hais yog tsis tshua muaj tseeb raws li zoo raws li high-zoo ntawm peb cov kev daws teeb meem yog incredibly zoo heev!

Peb vam khom raws li kev xav, kev hloov kho tshiab tsis tu ncua hauv txhua ntu, kev nce qib thev naus laus zis thiab tau kawg ntawm peb cov neeg ua haujlwm uas koom ncaj qha rau hauv peb txoj kev vam meej rau Kev Tsim Qauv Tshiab rau Tuam Tshoj Hoobkas Kub Muag Aluminium Machining Center for Aluminium Profile, Peb tos ntsoov muab koj nrog peb. cov khoom thaum nyob rau hauv ze ze rau lub sij hawm ntev, thiab koj yuav nrhiav tau peb cov lus hais yog tsis tshua muaj tseeb raws li zoo raws li high-zoo ntawm peb cov kev daws teeb meem yog incredibly zoo heev!

Tshiab zam tsim rauTuam Tshoj CNC Machining Centerr, Qhov rai Tshuab, Raws li ib txoj hauv kev siv cov peev txheej ntawm cov ntaub ntawv nthuav dav hauv kev lag luam thoob ntiaj teb, peb txais tos cov kev cia siab los ntawm txhua qhov chaw ntawm lub vev xaib thiab offline. Txawm hais tias muaj cov khoom zoo uas peb muab, kev pabcuam kev sib tham zoo thiab txaus siab yog muab los ntawm peb pab pawg pabcuam tomqab muag. Cov npe khoom thiab cov ncauj lus kom ntxaws thiab lwm yam ntaub ntawv weil raug xa tuaj rau koj raws sijhawm rau cov lus nug. Yog li thov hu rau peb los ntawm kev xa email rau peb lossis hu rau peb thaum koj muaj lus nug txog peb lub koom haum. koj tseem tuaj yeem tau txais peb qhov chaw nyob cov ntaub ntawv los ntawm peb lub xaib thiab tuaj rau peb lub lag luam. Peb tau txais ib daim ntawv ntsuam xyuas ntawm peb cov khoom. Peb cia siab tias peb yuav sib koom ua ke ua tiav thiab tsim kom muaj kev sib raug zoo nrog peb cov phooj ywg nyob rau hauv qhov chaw ua lag luam no. Peb tab tom nrhiav rau pem hauv ntej rau koj cov lus nug.