High-speed precision choj hom machining chaw CBS650

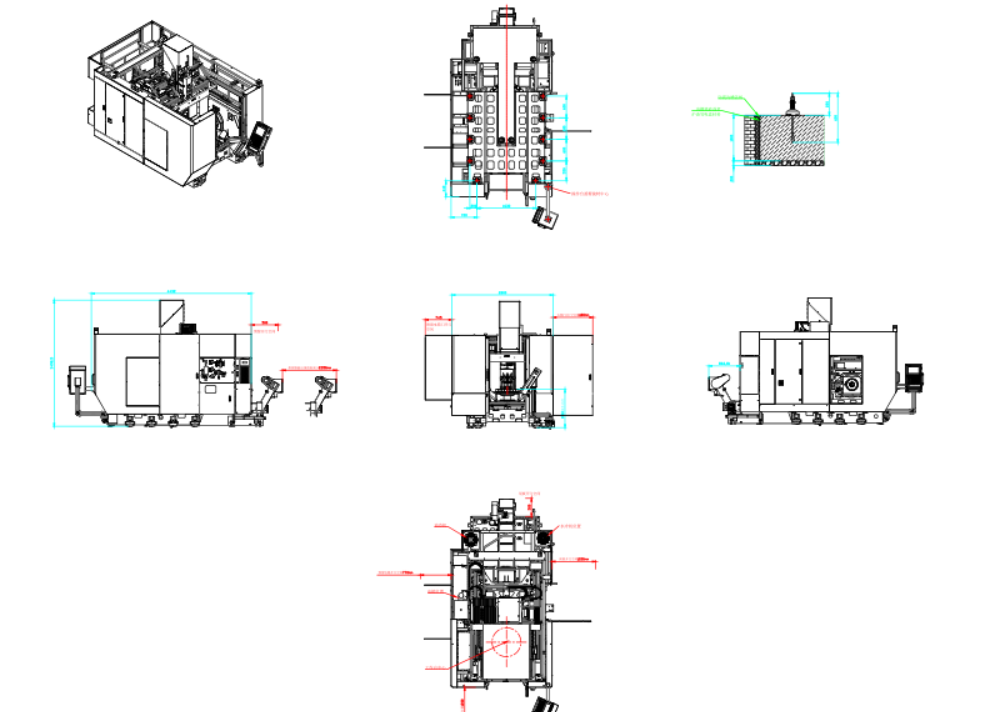

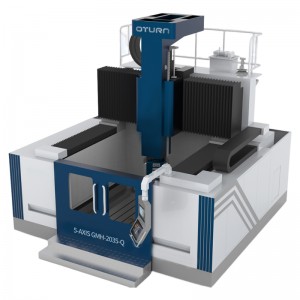

1.Machine Overview

CBS650 yog qhov kev kub ceev, kev ua haujlwm siab, siab precision choj hom 5-axis machining chaw nrog siab rigidity, siab precision thiab high efficiency. Lub tshuab tag nrho yog tsim los ntawm finite element tsom xam los muab qhov zoo tshaj plaws tag nrho kev ruaj ntseg kev ua tau zoo.

Peb axes nrawm nrawm 48 M / min, TT cov cuab yeej hloov lub sijhawm tsuas yog 4S, cov cuab yeej magazine tag nrho 24 teev cov cuab yeej hloov pauv yam tsis muaj lub tswb khiav lub tshuab thiab txhua lub tshuab sim ua qauv ntawm 3 zaug los ntawm cov khoom xeem, kom paub meej tias lub tshuab ua haujlwm tau zoo thiab nruam stability tom qab tawm hauv lub hoobkas. Nws yog haum rau txhua yam ntawm cov duab complex ntawm ob thiab peb seem concave thiab convex qauv uas yuav tsum tau 5-axis linkage rau thawj ua, thiab ntxiv, nws yog haum rau ob qho tib si me me thiab nruab nrab batch ntau hom ua ntau lawm, thiab kuj tuaj yeem nkag mus cov kab tsis siv neeg rau ntau lawm.

Qhov tseeb TNC640 system los ntawm HEIDENHAIN, nrog 15-nti loj LCD zaub, ntse ceeb toom zaub thiab kuaj tus kheej, ua rau lub tshuab siv tau yooj yim dua thiab tswj; ntau ntu kev nyeem ntawv ua ntej kev tswj hwm yog tshwj xeeb tshaj yog tsim rau kev ua haujlwm siab thiab muaj peev xwm loj, thiab txhawb nqa kev hloov pauv hauv network thiab USB kev pabcuam, uas pab txhawb kev xa mus sai thiab muaj txiaj ntsig ntawm cov kev pabcuam loj thiab kev ua haujlwm hauv online.

2.Main parameter

| Yam khoom | Chav tsev | specification | |

| Taug kev | X / Y / Z axis taug kev | mm | 800 × 900 × 560 hli |

| Qhov deb ntawm spindle kawg rau lub rooj saum npoo | mm | 110-670 : kuv | |

| Qhov siab tshaj plaws ntawm qhov chaw spindle mus rau lub rooj saum npoo ntawm 90 ° ntawm A-axis | mm | 560 | |

| Max machining ntau yam | mm | φ800 * 560 | |

| C-axis tigtable

| Txoj kab uas hla ntawm disc nto | mm | Φ650 |

| Turntable T-slot / phau ntawv qhia qhov dav dav | mm | 14H7/25H7 Nws | |

| Tso cai load | kg | 350 | |

| Peb-axis pub | X / Y / Z-axis hloov pauv sai | m/min | 48/48/48 ib |

| Txiav pub ceev | hli/min | 0-12000 Nws | |

| spindle | Spindle specifications (mounting txoj kab uas hla / kis txoj kev) | mm | 170 / sab hauv zais cia |

| Spindle taper bore | mm | A63 | |

| Qhov siab tshaj plaws spindle ceev | r / min | 18 000 | |

| Spindle lub cev muaj zog (nruam / S3 15%) | kW | 22/26 | |

| Spindle lub cev muaj zog torque (nruam / S3 15%) | Nm | 56.8/70 | |

| Cov cuab yeej Magzine | Cov cuab yeej magazine muaj peev xwm |

| 30 T |

| Cov cuab yeej pauv sijhawm (TT) | s | 4 | |

| Max. cuab tam diam | mm | 80/120 | |

| Max. cuab tam ntev | Mm | 300 | |

| Max. twj luj | kg | 8 | |

| Qhia Rail | X-axis kev taw qhia (qhov loj / tus lej ntawm cov swb) | mm | 452 ib |

| Y-axis kev taw qhia (qhov loj / tus lej ntawm cov swb) | 45/2 | ||

| Z-axis kev taw qhia (qhov loj me / tus lej ntawm cov swb) | 35/2 | ||

|

Peb Axes | X linear motor thrust (nruam / siab tshaj) | N | 3866/10438 ib |

| Y linear motor thrust (nruam / siab tshaj) | N | 3866/10438 ib | |

| Z-axis ntsia hlau | N | 2R40 * 20 (ob lub xov) | |

|

Tsib axis | C-axis ntsuas / siab tshaj plaws | rpm ua | 50/90 ib |

| C axis ntsuas / siab tshaj plaws txiav torque | Nm | 964/1690 ib | |

| A-axis positioning/repetition raug | arc-sec | 10/6 | |

| C-axis positioning/repetition raug | arc-sec | 8/4 | |

| Peb axis raug

| Positioning raug | mm | 0.005/300 |

| Rov ua dua qhov tseeb | mm | 0.003/300 | |

| Lubrication System

| Lubrication unit muaj peev xwm | L | 0.7 ua |

| Hom Lubrication |

| Roj lubrication | |

| Txiav kua | Dej tank peev xwm | L | 300 |

| Txiav twj tso kua mis parameter |

| 0.32Mpa × 16L / min | |

| lwm tus | Huab cua xav tau | kg/c ㎡ | ≥6 |

| Cua qhov chaw ntws tus nqi | mm3/min | ≥0.5 | |

| Fais fab mov muaj peev xwm | KVA | 45 | |

| Tshuab hnyav (combined) | t | 17 | |

| Qhov Loj (L × W × H) | mm | 2760 × 5470 × 3500 hli | |

3.Standard configuration

| 序号 | Lub npe |

| 1 | Siemens 840D system |

| 2 | Simultaneous tapping muaj nuj nqi |

| 3 | X / Y / Z / A / C tag nrho kaw lub voj kaw lus |

| 4 | X / Y / C axis ncaj qha tsav lub cev muaj zog tswj |

| 5 | X / Y / C axial kub tswj qhov system |

| 6 | Spindle kub tswj qhov system |

| 7 | Spindle overload tiv thaiv |

| 8 | Tag nrho cov ntaub ntawv hlau |

| 9 | Kev ruaj ntseg qhov rooj xauv qhov system |

| 10 | Tsis siv neeg qhov rooj ntawm lub cuab yeej magazine |

| 11 | Tsis siv neeg roj lubrication system |

| 12 | LED ua haujlwm teeb pom kev zoo |

| 13 | Mechanical tool setting thiab tool setting device (Medron) |

| 14 | Lifting nti conveyor system |

| 15 | Machining tshuab tshuab |

| 16 | Peripheral spraying system |

| 17 | Coolant system |

| 18 | Standard tool thiab toolbox |