High-speed Kab rov tav Machining Center CW Series

Configure

Nta

High-rigidity qauv enables high-precision ua

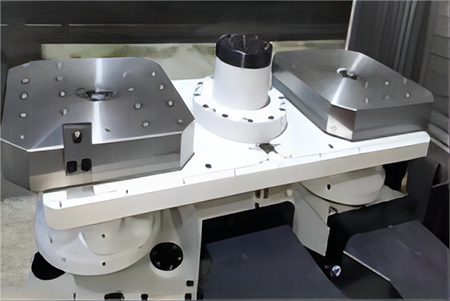

Coupling ntawm worktable: Kev sib txuas ntawm lub worktable lub cev thiab lub pallet yog nruj nreem kaw los ntawm 4-point cone nrog lub pallet clamping quab yuam ntawm 73.2KN. Lub coupling ntawm lub rooj indexing siv lub worktable clamping quab yuam ntawm 85.2KN los tswj kev ruaj khov ntawm kev txiav hnyav.

X-axis qaij tsim: Qhov sib txawv ntawm lub dav hlau qhov siab ntawm X-axis linear qhia ua kom muaj kev nruj nruj thiab ua tiav qhov chaw siab ceev thiab siab.

High-precision processing tsim

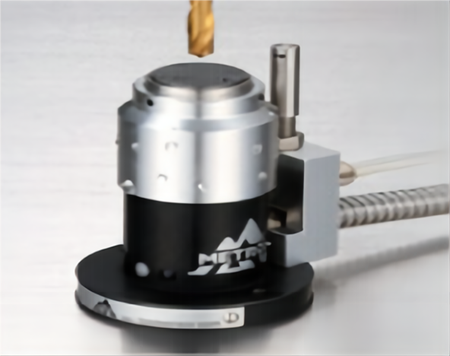

Built-in spindle / hluav taws xob spindle: Lub built-in spindle / motorized spindle ho txo kev vibration thaum lub sijhawm ua haujlwm siab, ua tiav qhov zoo tshaj plaws, thiab yog li txuas ntxiv lub neej ntawm cov cuab yeej.

Spindle kub tswj

Yuav kom ua tiav high-precision machining, coolant yog circulated los ntawm spindle bearings thiab spindle box kom txo thermal hloov nyob rau hauv spindle.

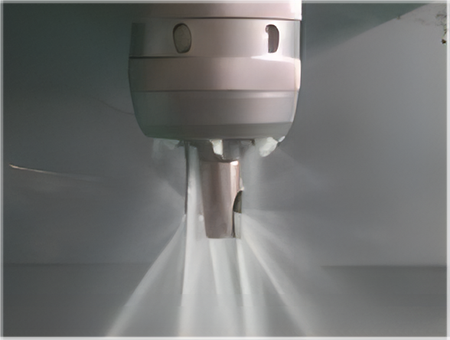

X, Y, Z axis pob screws nrog hollow txias: lub coolant, uas yog kub-tswj los ntawm lub txias chav tsev, circulates los ntawm lub axis ntawm lub pob ntsia hlau, yog li ua kom ruaj khov ua tiav ntawm kev ua haujlwm siab ceev nruam.

X, Y axis tiv thaiv npog: Cov ntawv ntau daim ntawv hlau tiv thaiv nrog txhuam yog hloov los ntawm accordion-style foldable guard. Qhov kev tsim compact no zoo tswj cov chips thiab txiav cov kua hauv thaj chaw machining.

Technical Specifications

| Yam khoom | Chav tsev | CWJ 4000 | CWJ 5000 | qw 6800 | qw 8800 | |

| Lub rooj ua haujlwm | Worktable (L × W) | mm | 400 × 400 hli | 500 × 500 | 630 × 630 hli | 800 × 800 hli |

|

| Tus naj npawb ntawmworktable | pcs | 2 | 2 | 2 | 2 |

|

| Max.Load ntawm worktable | kg | 300 | 500 | 1200 | 2000 |

|

| Max.workpiece loj ntawm worktable | mm | 0710 * 510 hli | 0800 * 1000 hli | 01100 * 1000 hli | 01450 * 1200 hli |

|

| Qhov siab ntawm worktable los ntawm av | mm | 1054 ib | 1165 ib | 1380 | 1400 |

|

| Tus nqi faib tsawg kawg nkaus | ° | 0.001 ib | 0.001 ib | 0.001 ib | 0.001 ib |

| Pub | X / Y / Z axis ceev txav | m/min | 60/60/60 ib | 60/60/60 ib | 60/60/60 ib | 60/60/60 ib |

|

| Txiav pub ceev | m/min | 1-10 | 1-10 | 1-10 | 1-10 |

| Mus ncig | X / Y / Z axis taug kev | mm | 500 × 450 × 400 hli | 800 × 800 × 800 hli | 1100 × 900 × 980 hli | 1500 × 1200 × 1325 hli |

|

| Kev ncua deb ntawm spindle center rau worktable | mm | 130-580 : kuv | 130-930 Nws | 150-1050 Nws | 100-1300 Nws |

| Spindle | Qhov deb ntawm spindle kawg mus rau worktable center | mm | 125-525 : kuv | 50-850 : kuv | 150-1130 Nws | 100-1425 : kuv |

|

| Spindle specifications (nruab txoj kab uas hla / kis hom) | mm | 170 / Built-in ib | 250 / Built-in | 300 / Built-in | 300 / Built-in |

|

| Spindle taper qhov | mm | BT40 | BT40 | BT50 | BT50 |

|

| Max.spindlespeb | r / min | 15000 | 15000 | 8000 | 8000 |

|

| Spindlemotorptus tswv | kW | 11/15 | 15/18.5 Nws | 18.5/30 Nws | 18.5/30 Nws |

|

| Spindlemotortorque | Nm | 32/53.4 | 95.5/250 | 305/623 | 305/623 |

| Cov cuab yeej | Toolmagazineckev paub | T | 23 | 50 | 40 | 40 |

|

| Max.tool uadiameter/length | mm | 110/250 ib | 150/500 | 250/500 | 250/500 |

|

| Max.tool uawyim | kg | 8 | 8 | 20 | 25 |

| Peb axis | X-axisguide uarua ail (rail Dav / Tus naj npawb ntawm Sliders) | mm | 35/2 | 45/2 | 55/2 | 55/6 |

|

| Y-axisguide uarua ail (rail Dav / Tus naj npawb ntawm Sliders) |

| 35/2 | 35/2 | 55/2 | 55/2 |

|

| Z-axisguide uarua ail (rail Dav / Tus naj npawb ntawm Sliders) |

| 35/2 | 45/2 | 55/4 | 65/4 ib |

|

| X-axis ntsia hlau | / | 2 R40 × 20 | 2 R40 × 20 | 2 R50 × 20 | 2 R50 × 20 |

|

| Y-axis ntsia hlau | / | 2 R40 × 20 | 2 R40 × 20 | 2 R50 × 20 | 2 R50 × 20 |

|

| Z-axis ntsia hlau | / | 2 R36 × 20 | 2 R40 × 20 | 2 R50 × 20 | 2 R50 × 20 |

| Qhov tseeb | Qhov chawaraug | mm | ± 0.005/300 | |||

|

| Rov ua duapkev sib thamaraug | mm | ± 0.003/300 | |||

| Lwm yam | Kev xav tau huab cua | kg/cm² | ≥6 | |||

|

| Gas ntws | L / min | ≥200 | |||

|

| Tshuabwyim (comprehensive) | T | 6 | 11.2 | 20 | 30 |

|

| Tshuab loj (L × W × H) | mm | 1680 * 5510 * 2870 | 2785 * 5845 * 3040 hli | 3300 * 6798 * 3400 hli | 4230 × 8447 × 3440 hli |

Configuration Taw Qhia

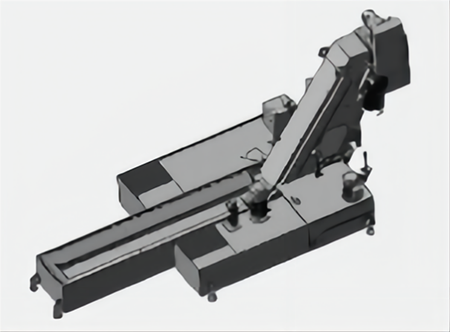

Muab ob npaug rau txauv worktable

Pem hauv ntej tsis siv neeg qhov rooj

Chaw nres tsheb Hydraulic

Toolsetter

(Tool breakage detection system)

Chain nti conveyor

Spindle CTS

(CTS siab 15 Bar)

Cov txheej txheem txheej txheem

Siv Machinery, Aerospace Kev Lag Luam, Automotive Kev Lag Luam

Tshiab zog roj teeb vaj tsev

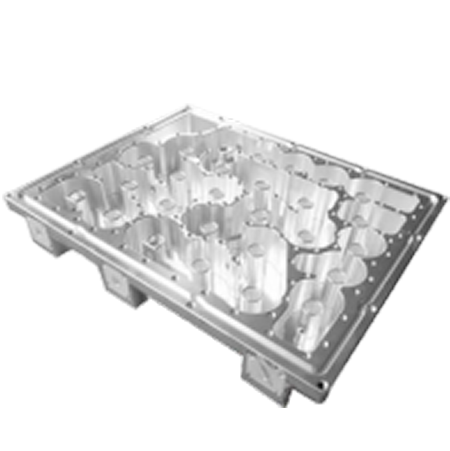

Groove Phaj

Transmission bearings

Splitter Plhaub

Kev sib txuas lus kab noj hniav

Clutch vaj tse

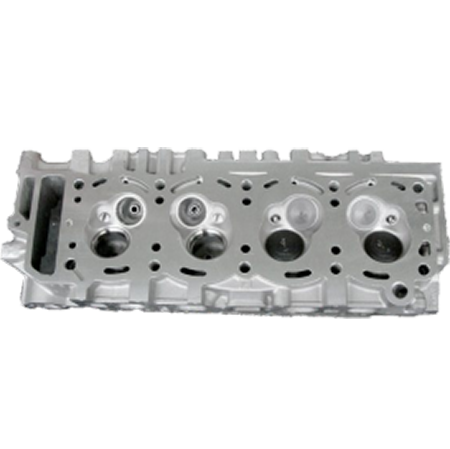

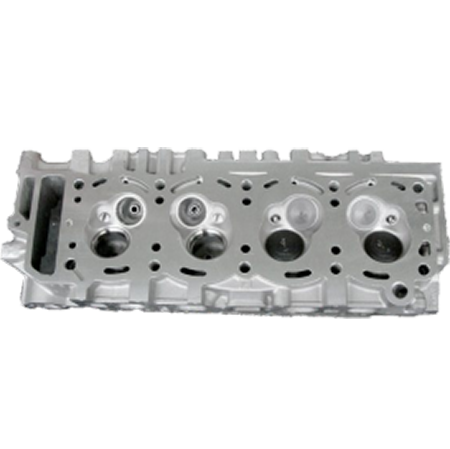

Lub tog raj kheej taub hau

Lub tog raj kheej taub hau