GM5X-I 5-axis CNC sib tsoo tshuab

Main qauv daim duab ntawm lub tshuab

Daim ntawv thov Scope

Lub tshuab no tsim qhov kawg milling cutter thiab laum, tsim nyog rau kev ua cov ntaub ntawv nyuaj alloy thiab high-speed steel.

Tool manufacturing thiab regrinding cycles

Txheem kawg mills: grooving, thaub qab, rake sharpening, hauv qab ntug sharpening, digitization, regrinding.

1. Kev qhia tshwj xeeb

| № | Cov ntsiab lus | Kev xav tau | Tus lej | Chav tsev |

| 1.1 | Workpiece Dimensions | |||

| 1.1.1 | Clamping ntev | ≤ | 230 | mm |

| 1.1.2 | Clamping txoj kab uas hla | nruab nrab | 2-20 | mm |

| 1.1.3 | Sib tsoo ntev | ≤ | 150 | mm |

| 1.1.4 | Sib tsoo txoj kab uas hla | nruab nrab | 0.3-12 | mm |

| 1.2 | Sib tsoo spindle | |||

| 1.2.1 | Tsav hom | Muaj tseeb | tsav ncaj qha | - |

| 1.2.2 | Hwj chim | rated zog | 13.6 | kW |

| 1.2.3 | Txias | Muaj tseeb | Roj txias | - |

| 1.2.4 ib | Kev tswj ceev ntawm kev sib tsoo log | Muaj tseeb | Stepless-ceev | - |

| 1.2.5 | Ceev | nruab nrab | 0-10000 | rpm ua |

| 1.2.6 | Tus naj npawb ntawm spindle sib tsoo taub hau | Muaj tseeb | 2 | pcs |

| 1.3 | Sib tsoo log | |||

| 1.3.1 | Txoj kab uas hla | ≤ | 150 | mm |

| 1.3.2 | Muaj pes tsawg tus sib tsoo log rau ib spindle | ≤ | 4 | pcs |

| 1.3.3 | Sib tsoo log spindle txoj kab uas hla | Muaj tseeb | 25 | mm |

| 1.3.4 | Program tswj coolant mov | Muaj tseeb | Yog lawm | - |

| 1.3.5 | Number of coolant nozzles | ≥ | 3 | pcs |

| 1.4 | Workpiece clamping system | |||

| 1.4.1 | Clamping system | Muaj tseeb | Hydraulic, tsis siv neeg | - |

| 1.4.2 | Clamping txoj hlua | Muaj tseeb | SCHAUBLIN W20 | - |

| 1.4.3 | Tsav hom | Muaj tseeb | tsav ncaj qha | - |

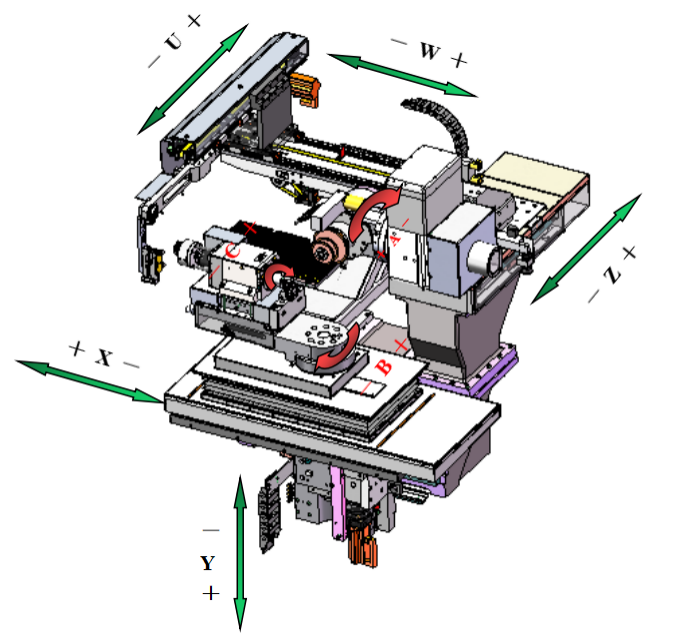

| 1.5 | Axis parameters | |||

| 1.5.1 | Hom | Muaj tseeb | kab tawm | - |

| 1.5.2 | X-axis taug kev | ≤ | 280 | mm |

| 1.5.3 | Z-axis taug kev | ≤ | 130 | mm |

| 1.5.4 ib | Y-axis taug kev | ≤ | 230 | mm |

| 1.5.5 | XYZ axis daws teeb meem | Muaj tseeb | 0.0001 | mm |

| 1.5.6 | XYZ axis ceev | ≤ | 10 | m/min |

| 1.5.7 ib | A-axis taug kev | ≤ | 360 | degree |

| 1.5.8 ib | A-axis daws teeb meem | Muaj tseeb | 0.0001 | degree |

| 1.5.9 ib | A-axis ceev | ≤ | 300 | rpm ua |

| 1.5.10 Nws | B-axis taug kev | ± | 210 | qib |

| 1.5.11 | B-axis ceev | ≤ | 12 | rpm ua |

| 1.6 | Loading thiab unloading system | |||

| 1.6.1 | Loading thiab unloading system | Muaj tseeb | Truss hom robotic caj npab | - |

| 1.6.2 | Tus naj npawb ntawm cov tais | Muaj tseeb | 2 | pcs |

| 1.6.3 | Automatic loading thiab unloading workpiece txoj kab uas hla | Nruab nrab | 2-12 | mm |

| 1.6.4 ib | Tsis siv neeg loading thiab unloading workpiece ntev | ≤ | 40-200 | mm |

| 1.6.5 ib | Muaj pes tsawg tus workpieces | ≤ | 300 | pcs |

| 1.6.6 | Software | Muaj tseeb | Yog lawm | - |

| 1.7 | Lwm yam khoom | |||

| 1.7.1 ib | Muaj peev xwm txheeb xyuas cov khoom ua haujlwm ntawm cov cuab yeej siv tshuab | Muaj tseeb | Yog lawm | - |

| 1.7.2 ib | Centralized tsis siv neeg lubrication system | Muaj tseeb | Yog lawm |

|

| 1.7.3 ib | Tricolor teeb liab teeb | Muaj tseeb | Yog lawm | - |

| 1.8 | xaiv tau | |||

| 1.8.1 ib | Cov khoom siv sib cais roj av | Muaj tseeb | xaiv tau | - |

| 1.9 | Tswj | |||

| 1.9.1 ib | Tswj qhov system | Muaj tseeb | NUCN-IM8+ | - |

| 1.9.2 ib | Kev ua haujlwm vaj huam sib luag | Muaj tseeb | Kov npo | - |

| 1.9.3 ib | Digital tswj axis | Muaj tseeb | Yog lawm | - |

| 1.9.4 ib | Xim zaub | Muaj tseeb | Yog lawm | - |

| 1.9.5 ib | Zaub Loj | Muaj tseeb | 19 | nti |

| 1.10 | Cov cuab yeej sib tsoo software module | |||

| 1.10.1 ib | Yooj yim milling cutters | Muaj tseeb | Yog lawm | - |

| 1.10.2 ib | Tej yam yooj yim xyaum | Muaj tseeb | Yog lawm | - |

| 1.10.3 ib | Tshawb xyuas tsis siv neeg nrhiav hom | Muaj tseeb | Yog lawm | - |

| 1.11 | Cov khoom siv hluav taws xob tsis zoo | |||

| 1.11.1 | Qhov hluav taws xob | Muaj tseeb | 380 ± 10% | V |

| 1.11.2 | Ntau zaus | Muaj tseeb | 50 ± 10% | Hz |

| 1.11.3 | Hwj chim | ≤ | 25 | KW |

| 1.12 | Qhov ntev | |||

| 1.12.1 | Ntev | ≤ | 2000 | mm |

| 1.12.2 | Dav | ≤ | 2 800 | mm |

| 1.12.3 | Qhov siab | ≤ | 2 200 | mm |

| 1.12.4 ib | Zoo | ≤ | 4 750 | kg |

2. Daim ntawv teev npe kev teeb tsa

| № | Cov ntsiab lus | Qauv | Hom | Tus lej | ||

| 2.1 | Tshuab cuab tam | |||||

| 2.1.1 | X-axis configuration | |||||

| 2.1.1.1 ib | - Screw pas nrig | Customized | NSK | 1 pcs | ||

| 2.1.1.2 | - Rail | 1 × MR25-A2-760-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2 pcs | ||

| 2.1.2 | Y-axis configuration | |||||

| 2.1.2.1 | - Screw pas nrig | Customized | NSK | 1 pcs | ||

| 2.1.2.2 | - Rail | 1 × MR35-C2-600-20-20-G2-V2+ MRK | SCHNEEBERGER | 2 pcs | ||

| 2.1.3 | Z-axis configuration | |||||

| 2.1.3.1 | - Screw pas nrig | Customized | NSK | 1 pcs | ||

| 2.1.3.2 | - Rail | 1 × MR25-A2-850-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2 pcs | ||

| 2.1.4 | A-axis configuration | |||||

| 2.1.4.1 | - Lub kaum sab xis encoder | ECN 113 | HEIDENHAIN | 1 pcs | ||

| 2.1.4.2 | - Direct tsav lub cev muaj zog | MSP-1000-2-002-158 | HIWIN | 1 pcs | ||

| 2.1.5 | B-axis tigtable | Customized | GuTian | 1 pcs | ||

| 2.1.6 | Permanent magnet ob lub taub hau hluav taws xob spindle | Rated zog 7.1KW | Chuangyun | 1 pcs | ||

| 2.1.7 | Peb axis truss manipulator | - | Chuangyun | 1 pcs | ||

| 2.1.8 ib | Tais | 148-NP-D4 | Chuangyun | 2 pcs | ||

| 2.1.9 | Tais | 148-NP-D6 | Chuangyun | 2 pcs | ||

| 2.1.10 Nws | Tais | 148-NP-D8 | Chuangyun | 2 pcs | ||

| 2.1.11 | Clamping puab tsaig | D0.5-3.2/D3.0-7.0/D7-13 | Chuangyun | 1set ib | ||

| 2.1.12 | High precision V-block | (3-5) | Chuangyun | 1 pcs | ||

| 2.1.13 | High precision V-block | (5-7) | Chuangyun | 1 pcs | ||

| 2.1.14 ib | High precision V-block | (6-12) | Chuangyun | 1 pcs | ||

| 2.1.15 Nws | Collet | D4W20 (80-00004) | SCHAUBLIN | 1 pcs | ||

| 2.1.16 | Kev sojntsuam | TS 150 | HEIDENHAIN | 1 pcs | ||

| 2.1.17 Nws | Sib tsoo log pas nrig (ntev) | 119 × ∅31.75 × ∅96mm | Chuangyun | 1 pcs | ||

| 2.1.18 | Sib tsoo log pas nrig (luv luv) | 87 × ∅31.75 × ∅96mm | Chuangyun | 1 pcs | ||

| 2.1.19 Nws | Cua txias | - | YUS | 1 pcs | ||

| 2.1.20 Nws | Tricolor teeb liab teeb | DC 24 V | Schneider | 1 pcs | ||

| 2.1.21 | Flowmeter | SIB 5000 | IFM | 1 pcs | ||

| 2.1.22 | Tsav lub zog tshwj xeeb | 15 KW | NEWCOM | 1 pcs | ||

| 2.1.23 | Electromagnetic valve pawg | M4GE280R-CX-E20D-5-3 | CKD | 1set ib | ||

| 2.1.24 ib | X, Y, Z-axis tsis siv neeg lubrication system | - | Taiwan | 1set ib | ||

| 2.2 | CNC system configuration | |||||

| 2.2.1 | BOXPC | IMPC00S/P1 | Newcon | 1 pcs | ||

| 2.2.2 | Lub zog lim | TSI 024A | NUM | 1 pcs | ||

| 2.2.3 | Lub zog lim | AGOFIL001S | NUM | 1 pcs | ||

| 2.2.4 | Kev tiv thaiv | AGORES008 | NUM | 1 pcs | ||

| 2.2.5 | System main power supply | MDLL3015N00AN0I | NUM | 1 pcs | ||

| 2.2.6 | Servo tsav tsheb | MDLUX021B1CAN0I | NUM | 4pcs ib | ||

| 2.2.7 | B-axis servo lub cev muaj zog | ZLS1002-H60-D3M1-NNSB-D16E40 | NUM | 1 pcs | ||

| 2.2.8 | A-axis lub cev muaj zog | MSP-1000-2-002-158 | NUM | 1 pcs | ||

| 2.2.9 | Y-axis servo lub cev muaj zog | ZLS1454-H30-DCM1-SNSB-D24E50 | NUM | 1 pcs | ||

| 2.2.10 | X / Z-axis servo lub cev muaj zog | ZLS1153-H30-D3M1-NNSB-D19E40 | NUM | 2 pcs | ||

| 2.2.11 | U / W axis servo tsav tsheb | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM | 2 pcs | ||

| 2.2.12 | V-axis servo lub cev muaj zog | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM | 1 pcs | ||

| 2.2.13 | Coupler | EX-1100 Nws | Newcon | 1 pcs | ||

| 2.2.14 ib | Tswv yim | EX-210 H | Newcon | 2 pcs | ||

| 2.2.15 | Tso zis | EX-310 H | Newcon | 2 pcs | ||

| 2.2.16 | Analog input module | TIAB SA - 4054 | Newcon | 1 pcs | ||

| 2.2.17 | Terminator | EX-TRE01 | Newcon | 1 pcs | ||

| 2.2.18 | Kev ua haujlwm vaj huam sib luag | PIB 4106/H | Newcon | 1 pcs | ||

| 2.2.19 | NCK | IM8+ | Newcon | 1 pcs | ||

| 2.2.20 Nws | NCK | TIAB SA 100006 | Newcon | 1 pcs | ||

| 2.2.21 | NCK | TIAB SA 100008 | Newcon | 1 pcs | ||

| 2.2.22 | NCK | TIAB SA 100012 | Newcon | 1 pcs | ||

| 2.2.23 | NCK | PIB 100586 | Newcon | 1 pcs | ||

| 2.2.24 ib | NCK | TIAB SA 100373 | Newcon | 1 pcs | ||

| 2.2.25 Nws | NCK | TIAB SA 100375 | Newcon | 1 pcs | ||

| 2.2.26 | NCK | TIAB SA 100335 | Newcon | 1 pcs | ||

| 2.2.27 ib | NCK | TIAB SA 100519 | Newcon | 1 pcs | ||

| 2.2.28 | NCK | TIAB SA 100392 | Newcon | 1 pcs | ||

| 2.2.29 ib | NCK | TIAB SA 100331 | Newcon | 1 pcs | ||

| 2.2.30 Nws | NCK | TIAB SA 100535 | Newcon | 1 pcs | ||

| 2.2.31 Nws | NCK | TIAB SA 100520 | Newcon | 1 pcs | ||

| 2.2.32 Nws | NCK | TIAB SA 100560 | Newcon | 1 pcs | ||

| 2.3 | Standard configuration ntawm cov cuab yeej sib tsoo software | |||||

| 2.3.1 | Yooj yim milling cutter | Chuangyun tus kheej tsim | 1 pcs | |||

| 2.3.2 | Yooj yim xyaum | Chuangyun tus kheej tsim | 1 pcs | |||

| 2.3.3 | 3D kev sib tsoo xyuas nrog 3D tshuab simulation | Chuangyun tus kheej tsim | 1 pcs | |||

| 2.3.4 | 3D cuab yeej simulation | Chuangyun tus kheej tsim | 1 pcs | |||

| 2.3.5 | Tshawb nrhiav tsis siv neeg | Chuangyun tus kheej tsim | 1 pcs | |||