Tsib-axis Vertical Machining Center CV Series

Nta

Tshuab taw qhia

Lub tsib-axis ntsug machining chaw CV series muaj cov yam ntxwv ntawm siab rigidity, siab precision thiab high efficiency machining. Lub kem txais ib qho kev tsim herringbone nrog rau qhov loj, uas tuaj yeem txhim kho qhov khoov thiab torsional zog ntawm kem; lub workbench txais yuav ib tug tsim nyog slider ncua thiab yog nto quenched, kom lub zog ntawm lub workbench yog uniform thiab hardness yog zoo dua; lub txaj txais lub trapezoidal cross-section, txo Qhov chaw ntawm lub ntiajteb txawj nqus txhim kho lub zog torsional; tag nrho lub tshuab siv finite caij tsom xam los tsim txhua yam khoom kom muaj kev ruaj ntseg zoo tshaj plaws.

Qhov ceev tshaj plaws peb-axis hloov pauv sai tshaj plaws tuaj yeem ncav cuag 48M / min, TT lub sijhawm hloov pauv tsuas yog 2.5S, cov cuab yeej magazine tau ntim tag nrho rau 24t. Nws yog qhov tsim nyog rau ntau yam 2D thiab 3D concave-convex qauv nrog cov duab nyuaj thiab cov kab noj hniav nyuaj thiab qhov chaw. Nws kuj yog tsim rau milling, drilling, expanding, tho txawv, Tapping thiab lwm yam txheej txheem yog ntau haum rau ob qho tib si me me thiab nruab nrab-qhov loj me batches ntawm ntau ntau yam ua thiab ntau lawm, thiab kuj yuav siv tau nyob rau hauv tsis siv neeg kab rau loj ntau lawm.

Lub dynamic graphic zaub ntawm cov cuab yeej khiav, ntse ceeb toom zaub, kuaj tus kheej thiab lwm yam dej num ua rau kev siv thiab tu lub tshuab cuab yeej yooj yim dua thiab ceev; Kev nyeem ntawv muaj peev xwm nce mus txog 3000 kab / thib ob, uas pab txhawb kev sib kis tau sai thiab muaj txiaj ntsig thiab ua haujlwm online ntawm cov kev pabcuam loj.

RTCP (Rotation Tool center Point) ntawm tsib-axis machining chaw yog lub cuab yeej taw tes taw tes tswj kev ua haujlwm. Tom qab tig rau RTCP muaj nuj nqi, tus maub los yuav hloov los ntawm kev tswj hwm lub ntsej muag kawg ntawm lub cuab yeej los tswj cov cuab yeej taw tes. Cov lus qhia hauv qab no tuaj yeem them nyiaj rau qhov linearity tshwm sim los ntawm cov rotary axis. Yuam kev los tiv thaiv Tool kev sib tsoo. Ntawm point A ntawm lub workpiece, qhov nruab nrab ntawm lub cuab yeej axis hloov ncaj qha los ntawm txoj kab rov tav mus rau txoj hauj lwm ntsug. Yog tias qhov kev ua yuam kev tsis raug kho, lub cuab yeej lub cuab yeej yuav sib txawv ntawm qhov point A lossis txawm tias nkag mus rau qhov chaw ua haujlwm, ua rau muaj kev sib tsoo loj. Vim tias qhov kev txav mus tas li ntawm lub viav vias axis thiab lub rotary axis ua rau muaj kev hloov pauv ntawm txoj haujlwm ntawm point A, cov cuab yeej tseem ceeb ntawm txoj haujlwm yuav tsum raug kho kom ntseeg tau tias cov cuab yeej taw qhia txoj hauj lwm sib koom ua ke yeej ib txwm tsis hloov pauv mus rau point A, zoo li yog. Lub cuab yeej taw tes yog txav nrog point A., qhov no yog lub ntsis ntawm lub cuab tam hauv qab no.

Qhov kev ua haujlwm no muaj 0 ~ 9 qib, qib 9 yog qhov siab tshaj plaws, thaum lub 1st - 8th theem them nyiaj rov qab servo yuam kev, thiab muab txoj kev ua kom zoo smoothness.

High-speed thiab High-precision Peb-dimensional ua

Lub siab ceev spindle, 3D arc machining tswj tau ua ntej nyeem 2000blocks thiab kho txoj kev du rau high-speed thiab high-precision machining.

High Rigidity Structure

Txhim kho daim ntawv ntawm cov qauv thiab ua kom zoo tshaj qhov kev faib tawm los txhim kho lub tshuab rigidity. Cov duab ntawm cov cuab yeej siv tshuab thiab kem thiab kev faib ua kom zoo tshaj plaws yog cov qauv tsim nyog tshaj plaws los ntawm CAE tsom xam. Ntau yam kev txhim kho kev ntsuas uas pom tsis pom sab nraud yog xav txog qhov muaj peev xwm txiav ruaj khov uas lub spindle ceev tsis tuaj yeem pom.

Technical Specifications

| Yam khoom | chav tsev | CV 200 | SIB 300 | CV 500 | |

| Mus ncig

| X / Y / Z axis taug kev | mm | 500 × 400 × 330 hli | 700 * 600 * 500 hli | 700 × 600 × 500 hli |

| Kev ncua deb ntawm spindle kawg lub ntsej muag mus rau worktable nto | mm | 100-430 Nws | 150-650 Nws | 130-630 Nws | |

| Kev ncua deb ntawm spindle center mus rau kem qhia rail nto | mm | 412 | 628 ib | 628 ib | |

| Qhov siab tshaj plaws nyob nruab nrab ntawm A-axis 90 ° spindle center thiab C-axis disk nto | mm | 235 | 360 | 310 | |

| 3 axis pub

| X / Y / Z axis hloov pauv sai | m/min | 48/48/48 ib | 48/48/48 ib | 36/36/36 ib |

| Txiav pub tus nqi | hli/min | 1-24 000 Nws | 1-24 000 Nws | 1-24 000 Nws | |

| Spindle

| Spindle specifications (nruab txoj kab uas hla / kis hom) | mm | 95/ ib | 140/ Direct | 140/ Direct |

| Spindle taper | mm | BT30 | BT40 | BT40 | |

| Spindle ceev | r / min | 12000 | 12000 | 12000 | |

| Spindle lub cev muaj zog (nruam / S3 25%) | kW | 8.2/12 | 15/22.5 Nws | 15/22.5 Nws | |

| Spindle Tsav Torque (Nruam / S3 25%) | Nm | 26/38 ib | 47.8/71.7 | 47.8/71.7 | |

| Tool magazine

| Cov ntawv xov xwm muaj peev xwm | T | 21 T | 24 T | 24 T |

| Lub sijhawm hloov cuab yeej (TT) | s | 2.5 | 4 | 4 | |

| Max.Tool txoj kab uas hla (tag nrho cov cuab yeej / cov cuab yeej khoob) | mm | 80 | 70/120 ib | 70/120 ib | |

| Max.Tool length | mm | 250 | 300 | 300 | |

| Max. Tool hnyav | kg | 3 | 8 | 8 | |

| Qhia

| X-axis phau ntawv qhia (loj/ntaus sliders) | mm | 30/2 | 35/2 khob | 45/2 khob |

| Y-axis phau ntawv qhia (qhov ntev / qhov ntau ntawm sliders) |

| 30/2 | 35/2 khob | 45/2 khob | |

| Z-axis phau ntawv qhia (qhov ntev / qhov ntau ntawm sliders) |

| 30/2 | 35/2 khob | 45/2 khob | |

|

Ntsia hlau

| X-axis ntsia hlau |

| Φ28 × 16 | Φ40 × 16 | Φ40 × 16 |

| Y-axis ntsia hlau |

| Φ28 × 16 | Φ40 × 16 | Φ40 × 16 | |

| Z axis ntsia hlau |

| Φ32 × 16 | Φ40 × 16 | Φ40 × 16 | |

| Qhov tseeb

| Positioning raug | mm | ± 0.005/300 | ± 0.005/300 | ± 0.005/300 |

| Rov ua dua | mm | ± 0.003/300 | ± 0.003/300 | ± 0.003/300 | |

| 5 axis

| Turntable tsav txoj kev |

| Moter ncaj qha | Roller cam | roller cam |

| Turntable txoj kab uas hla | mm | Φ200 | Φ300 * 250 | φ500 * 400 | |

| Tso cai load hnyav ntawm turntable (nyob rau hauv kab rov tav / inclined) | kg | 40/20 | 100/70 | 200 | |

| A / C-axis max. ceev | rpm ua | 100/230 ib | 60/60 ib | 60/60 ib | |

| A-axis positioning/repeatability | arc-sec | 10/6 | 15/10 | 15/10 | |

| C-axis positioning/repeatability | arc-sec | 8/4 | 15/10 | 15/10 | |

| Lubrication

| Lubrication unit muaj peev xwm | L | 1.8 | 1.8 | 1.8 |

| Roj separator hom |

| volumetric | Roj lubrication | volumetric | |

| Lwm tus

| Huab cua xav tau | kg/c ㎡ | ≥6 | ≥6 | ≥6 |

| Cua qhov chaw ntws | mm3/min | ≥0.2 | ≥0.4 | ≥0.4 | |

| roj teeb muaj peev xwm | KVA | 10 | 22.5 ib | 26 | |

| Tshuab Luj (Comprehensive) | t | 2.9 | 7 | 8 | |

| Mechanical Dimensions (L × W × H) | mm | 1554 × 2346 × 2768 | 2248 * 2884 * 2860 | 2610 × 2884 × 3303 | |

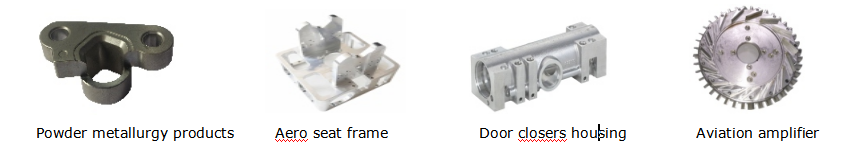

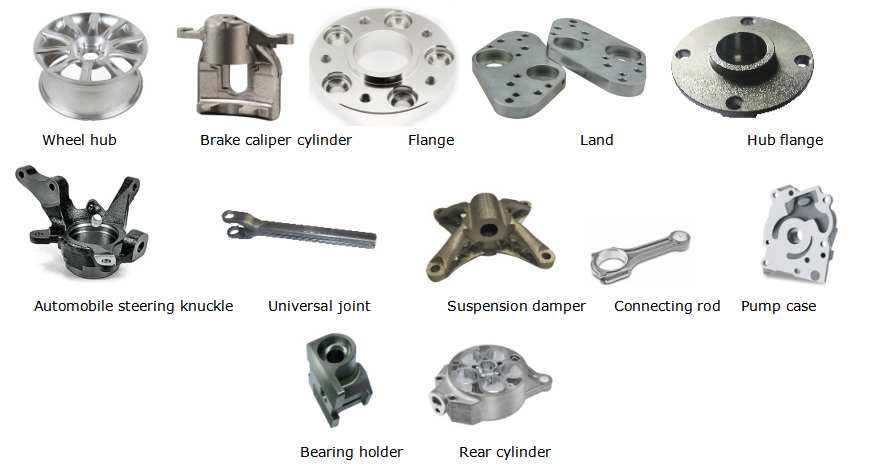

Ua piv txwv

1.Automotive kev lag luam

2.Precision fixture

3. Tub rog kev lag luam