Tsib-axis ntsug machining chaw CBS series

Nta

1.Main kev ua tau zoo zoo

1.1.The X-axis txais kev tsav ncaj qha thev naus laus zis, Y-axis txais kev sib txuas ncaj qha tsav tshuab thiab kev tswj hwm synchronous, nrog lub zog siab, tsis tshua muaj suab nrov, teb ceev ceev, thiab kev ua haujlwm zoo heev. Peb-axis ntawm X / Y / Z tag nrho txais yuav high-precision linear grating tawm tswv yim, nrog siab positioning raug

1.2.Qhov siab-torque lub cev muaj zog tsav lub A-axis thiab C-axis tig, nrog xoom xaim saw, xoom rov qab, thiab zoo rigidity; lub high-precision lub kaum sab xis encoder ua tiav qhov chaw ua haujlwm

1.3.Lub spindle txais cov qauv hluav taws xob ceev ceev nrog kev kub ceev thiab tsis tshua muaj suab nrov.

2.High-rigidity choj qauv

2.1.Lub CBS series txais yuav ib tug choj qauv layout, thiab X / Y / Z ua tiav cov lus tsa suab, uas tsis cuam tshuam los ntawm qhov hnyav ntawm A / C axis.

2.2.Lub A / C axis ua haujlwm ntawm nws tus kheej, thiab qhov hnyav ntawm lub workpiece tsis cuam tshuam rau lwm qhov peb axis.

2.3.Cov qauv gantry thiab lub viav vias thiab cov lus teb txhawb nqa ntawm ob qho kawg tuaj yeem tswj xyuas cov txheej txheem siab rau lub sijhawm ntev.

3.Efficient tig muaj nuj nqi

4.High-speed thiab high-rigidity rotary rooj paub meej milling thiab xa cov khoom sib xyaw ua ke

Lub precision tsib-axis teb lub rooj ncaj qha tsav los ntawm lub cev muaj zog torque yog siv hauv CNC tshuab cuab yeej thiab tuaj yeem ua tsib-axis ib txhij ua. Nws muaj qhov zoo ntawm kev kub ceev, siab precision, stability thiab kev cia siab, thiab kev ua haujlwm yooj yim.

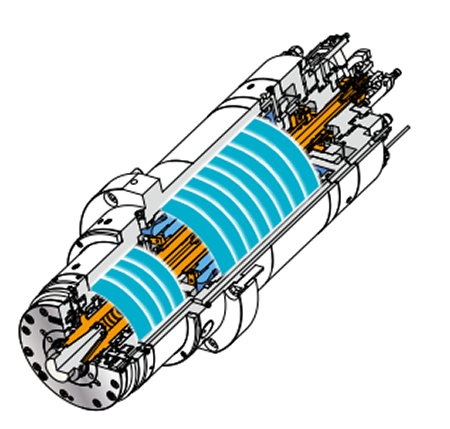

5.Txoj kev ua haujlwm siab precision machining spindles

Mastering technologies tseem ceeb thiab nws tus kheej tsim cov spindles

Oturn tau paub txog cov thev naus laus zis tseem ceeb thiab muaj peev xwm tsim, tsim khoom thiab sib sau cov spindles. Nrog rau 1000m2 qhov kub thiab txias rhiav thiab ib tug sophisticated modular ntau lawm qauv, Oturn spindles muaj cov yam ntxwv ntawm siab rigidity, siab ceev, siab zog, siab torque thiab siab ntseeg.

Tus kheej tsim HSKE40 / HSKA63 / HSKA100 built-in spindle yog saws. Nyob rau hauv qhov kev sib hloov spindle, qhov kev vibration thiab kev vibration raug tshem tawm kom ua tiav qhov tseeb ntawm kev kub ceev thiab kev ua haujlwm ntev. Lub spindle siv yuam kom txias kom txias lub cev muaj zog thiab pem hauv ntej thiab nram qab bearings.

6.Built-in lub cev muaj zog qauv

Los ntawm kev tshem tawm cov iav tsav, kev co thaum lub sij hawm kev sib hloov ceev tuaj yeem raug txo kom tsawg, yog li txhim kho qhov tseeb ntawm lub tshuab machined nto thiab txuas lub neej ntawm lub cuab yeej.

7.Spindle kub tswj

Los ntawm circulating cov kub-tswj txias txias roj, lub thermal displacement ntawm spindle tshwm sim los ntawm lub tshav kub generated los ntawm txhua yam yuav tsum suppressed, yog li tiv thaiv kev hloov ntawm machining raug.

8.Leading lub ntiaj teb no nyob rau hauv linear motors

Linear motors

8.1.Equipped nrog linear tsav tsav, tsis muaj txhua yam kev sib cuag thaum lub sij hawm txav, tsis muaj mechanical poob, tsis muaj backlash kis tau tus mob, thiab ceev teb ceev.

8.2.Absolute optical scale rau tag nrho kaw-voj tswj.

Tsis muaj grating tus pas ntsuas, nanometer-theem nrhiav kom raug, kev daws teeb meem txog 0.05μm, kom ua tiav tag nrho kaw-voj tswj.

9.Excellent ergonomic tsim

Raws li ergonomic tsim, nws yog ib qho yooj yim rau cov tswv siv thiab txhim kho kev ua haujlwm thiab kev tswj xyuas.

9.1.Kev nkag tau zoo heev

Txhawm rau txhim kho qhov kev ua tau zoo ntawm kev nkag mus rau qhov chaw ua haujlwm, lub hau npog hauv qab ntawm lub qhov rooj ua haujlwm tau thim rov qab mus rau sab ntawm lub rooj zaum ua haujlwm kom muaj chaw ua haujlwm txaus.

9.2.Qhov rai loj rau kev soj ntsuam yooj yim ntawm kev ua haujlwm

Lub qhov rais loj ua rau nws yooj yim los soj ntsuam cov txheej txheem ua haujlwm ntawm lub workpiece. Tshwj xeeb, nquag pom zoo ntawm kev txiav thiab kev hloov pauv hauv kev ua haujlwm thaum lub sijhawm ua haujlwm hloov kho kuj tuaj yeem ua tiav yooj yim, txhim kho kev ua haujlwm.

9.3.Centralized configuration ntawm tu units

Txhawm rau txhim kho qhov kev ua tau zoo ntawm kev nkag mus rau qhov chaw ua haujlwm, lub hau npog hauv qab ntawm lub qhov rooj ua haujlwm tau thim rov qab mus rau sab ntawm lub rooj zaum ua haujlwm kom muaj chaw ua haujlwm txaus.

9.4.Wide lub qhov rooj rau kev nkag tau yooj yim los ntawm crane

Thaum ua haujlwm xws li hloov chaw ua haujlwm, kev ua haujlwm ntawm cov neeg ua haujlwm tuaj yeem raug txo, thiab tib lub sijhawm, muaj qhov chaw ua haujlwm txaus thaum siv lub crane.

9.5.Nyob zoo thiab tus phooj ywg ua haujlwm vaj huam sib luag

Lub vaj huam sib luag ua haujlwm rotatable uas ua raws li qhov siab ntawm tib neeg lub cev tso cai rau tus neeg teb xov tooj ua haujlwm thiab ua haujlwm lub tshuab ua haujlwm zoo.

Technical Specifications

| Yam khoom | CBS 200 | CBS 200 C | CBS 300 | CBS 300 C | CBS400 | CBS 400 C | |

| Mus ncig | X / Y / Z axis taug kev | 300 * 350 * 250 hli | 300 * 350 * 250 hli | 460 * 390 * 400 hli | |||

| Kev ncua deb ntawm lub ntsej muag spindle mus rau qhov chaw ua haujlwm | 130-380 : kuv | 130-380 : kuv | 155-555 : kuv | ||||

| Spindle | Spindle taper | E40 | E40 | E40 | |||

| Max. spindle ceev | 30000 | 30000 | 30000 | ||||

| Spindle lub cev muaj zog (nruam / S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| Spindle lub cev muaj zog torque (nruam / S325%) | 11.5/13.8 Nws | 11.5/13.8 Nws | 11.5/13.8 Nws | ||||

| Pub |

Ceev ceev ntawm X / Y / Z axis (m / min)

| 48/48/48 ib | 48/48/48 ib | 30/30/30 ib | |||

| Txiav pub (mm / min) | 1-24 000 Nws | 1-24 000 Nws | 1-12000 Nws | ||||

| Rotary rooj | Rotary rooj diam | 200 | 300 | 400 | |||

| Tso cai load hnyav | 30 | 20 | 40 | 25 | 250 | 100 | |

| A-axis tilting lub kaum sab xis | ± 110 ° | ± 110 ° | ± 110 ° | ||||

| C-axis tig | 360 ° | 360 ° | 360 ° | ||||

| A-axis ntsuas / max.speed | 47/70 ib | 47/70 ib | 30/60 ib | ||||

| A-axis Rated/max.torque | 782/1540 ib | 782/1540 ib | 940/2000 ib | ||||

| C-axis ntsuas / max.speed | 200/250 | 1500/2000 ib | 200/250 | 1500/2000 ib | 100/150 | 800/1500 | |

| C-axis ntsuas / max.torque | 92/218 ib | 15/30 ib | 92/218 ib | 15/30 ib | 185/318 ib | 42/60 ib | |

| A-axis positioning raug/repeatability | 10/6 | 10/6 | 10/6 | ||||

| C-axis positioning raug/repeatability | 8/4 | 8/4 | 8/4 | ||||

| ATC | Cov cuab yeej magazine muaj peev xwm | 16 | 16 | 26 | |||

| Tool max. txoj kab uas hla/ ntev | 80/200 | 80/200 | 80/200 | ||||

| Max.tool luj | 3 | 3 | 3 | ||||

| Tool hloov lub sij hawm (lub cuab tam rau cuab tam) | 4 | 4 | 4 | ||||

| Peb- axis | X-axis qhia (linear qhia dav / tus lej sliders) | 30/2 | 30/2 | 35/2 | |||

| X-axis qhia (linear qhia dav / tus lej sliders) | 35 / 2 + 30 / 2 | 35 / 2 + 30 / 2 | 45/2 | ||||

| Z-axis qhia (linear qhia dav / tus lej sliders) | 25/2 | 25/2 | 35/2 | ||||

| X-axis linear lub cev muaj zog (nruam / max.) | 1097/2750 ib | 1097/2750 ib | φ40 × 10 (ntsia hlau) | ||||

| Y-axis linear lub cev muaj zog (nruam / max.) | 3250/8250 | 3250/8250 |

| ||||

| Z-axis linear lub cev muaj zog (nruam / max.) | 1033/1511 ib | 1033/1511 ib |

| ||||

| Qhov tseeb | Positioning raug | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Rov ua dua | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Lub zog | Fais fab mov muaj peev xwm | 25 | 30 | 25 | 30 | 30 | 35 |

| Cua siab | ≥0.6Mpa ≥400L / min | ≥0.6Mpa ≥400L / min | ≥0.6Mpa ≥400L / min | ||||

| Tshuab loj | Tshuab loj | 1920 * 3030 * 2360 hli | 1920 * 3030 * 2360 hli | 2000 * 2910 * 2850 | |||

| Tshuab loj (xws li nti conveyor thiab lwm yam khoom siv peripheral) | 3580 * 3030 * 2360 hli | 3580 * 3030 * 2360 hli | 3360 * 2910 * 2850 | ||||

| Qhov hnyav | 4.8 t ib | 4.8 t ib | 5T | ||||

| Yam khoom | CBS 500 | CBS 500 C | SWB 650 | CBS 650 C | CBS 800 | CBS 800 C | |

| Mus ncig | X / Y / Z axis taug kev | 500 * 600 * 450 hli | 650 * 800 * 560 hli | 800 * 910 * 560 | |||

| Kev ncua deb ntawm lub ntsej muag spindle mus rau qhov chaw ua haujlwm | 130-580 : kuv | 110-670 : kuv | 100-660 : kuv | ||||

| Spindle | Spindle taper | A63 | A63 | A63 | |||

| Max. spindle ceev | 20000 | 20000 | 20000 | ||||

| Spindle lub cev muaj zog (nruam / S325%) | 30/34 ib | 30/34 ib | 30/34 ib | ||||

| Spindle lub cev muaj zog torque (nruam / S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Pub | Ceev ceev ntawm X / Y / Z axis (m / min)

| 48/48/48 ib | 48/48/48 ib | 48/48/48 ib | |||

| Txiav pub (mm / min) | 1-24 000 Nws | 1-24 000 Nws | 1-24 000 Nws | ||||

| Rotary rooj | Rotary rooj diam | 500 | 650 | 800 | |||

| Tso cai load hnyav | 600 | 240 | 800 | 400 | 1000 | 400 | |

| A-axis tilting lub kaum sab xis | ± 110 ° | ± 110 ° | ± 110 ° | ||||

| C-axis tig | 360 ° | 360 ° | 360 ° | ||||

| A-axis ntsuas / max.speed | 60/80 ib | 40/8 C | 40/80 ib | ||||

| A-axis Rated/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| C-axis ntsuas / max.speed | 80/120 | 600/1000 | 50/80 ib | 450/800 Nws | 50/80 ib | 450/800 Nws | |

| C-axis ntsuas / max.torque | 355/685 ib | 160/240 ib | 964/1690 ib | 450/900 ib | 964/1690 ib | 450/900 ib | |

| A-axis positioning raug/repeatability | 10/6 | 10/6 | 10/6 | ||||

| C-axis positioning raug/repeatability | 8/4 | 8/4 | 8/4 | ||||

| ATC | Cov cuab yeej magazine muaj peev xwm | 25 | 30 | 30 | |||

| Tool max. txoj kab uas hla/ ntev | 80/300 ib | 80/300 ib | 80/300 ib | ||||

| Max.tool luj | 8 | 8 | 8 | ||||

| Tool hloov lub sij hawm (lub cuab tam rau cuab tam) | 4 | 4 | 4 | ||||

| Peb- axis | X-axis qhia (linear qhia dav / tus lej sliders) | 35/2 | 45/2 | 45/2 | |||

| X-axis qhia (linear qhia dav / tus lej sliders) | 45/2 | 45/2 | 45/2 | ||||

| Z-axis qhia (linear qhia dav / tus lej sliders) | 35/2 | 35/2 | 35/2 | ||||

| X-axis linear lub cev muaj zog (nruam / max.) | 2167/5500 ib | 3250/8250 | 3250/8250 | ||||

| Y-axis linear lub cev muaj zog (nruam / max.) |

|

|

| ||||

| Z-axis linear lub cev muaj zog (nruam / max.) | 2 R40 * 20 (ntsia hlau) | 2 R40 * 20 (ntsia hlau) | 2 R40 * 20 (ntsia hlau) | ||||

| Qhov tseeb | Positioning raug | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Rov ua dua | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Lub zog | Fais fab mov muaj peev xwm | 40 | 45 | 55 | 70 | 55 | 70 |

| Cua siab | ≥0.6Mpa ≥400L / min | ≥0.6Mpa ≥400L / min | ≥0.6Mpa ≥400L / min | ||||

| Tshuab loj | Tshuab loj | 2230 * 3403 * 3070 hli | 2800 * 5081 * 3500 | 2800 * 5081 * 3500 | |||

| Tshuab loj (xws li nti conveyor thiab lwm yam khoom siv peripheral) | 2230 * 5540 * 3070 hli | 2800 * 7205 * 3500 hli | 2800 * 7205 * 3500 hli | ||||

| Qhov hnyav | 11 T | 15 T | 15.5 t ib | ||||

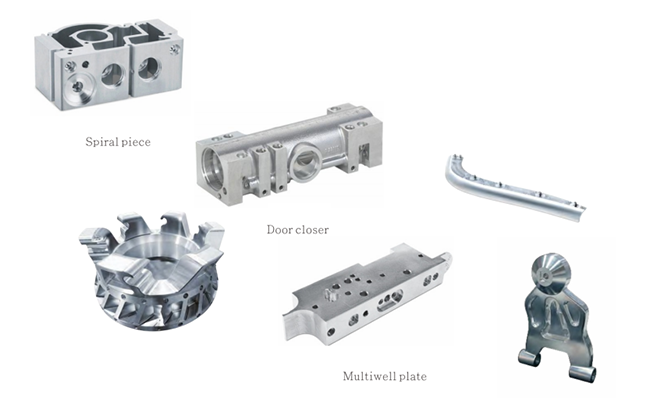

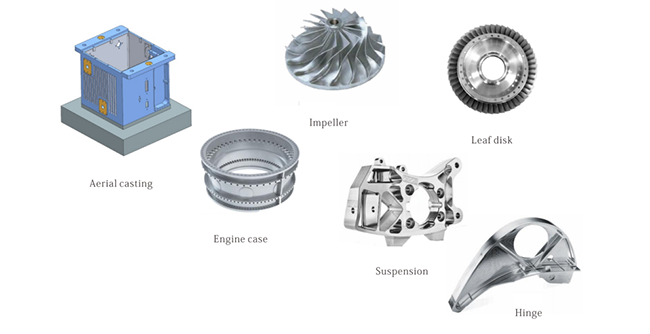

Cov txheej txheem txheej txheem

1.Automotive kev lag luam

2.Aerospace

3.Kev tsim kho tshuab