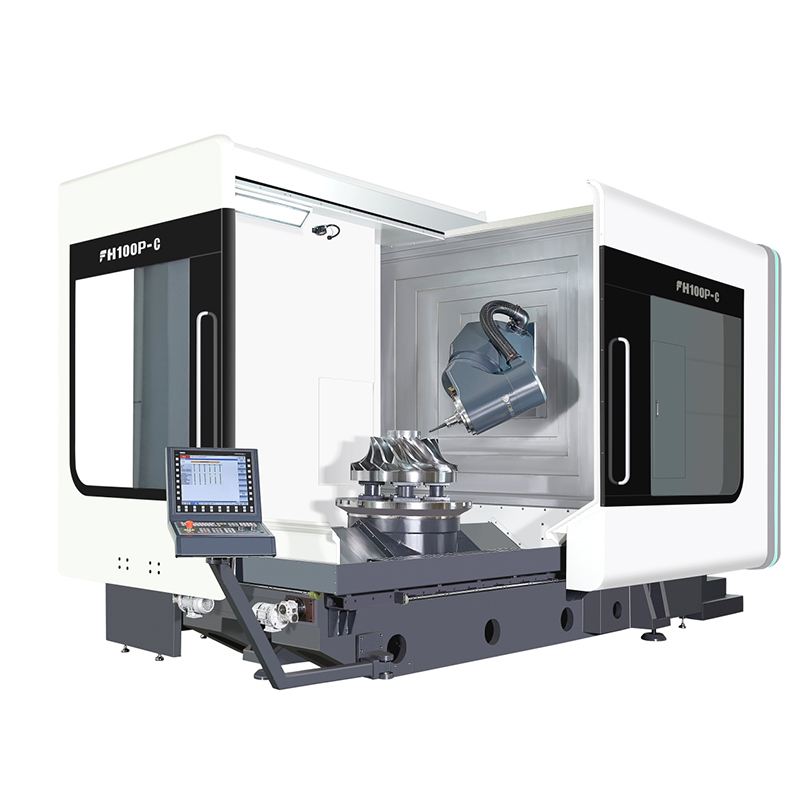

Tsib-axis Machining Center FH100P

Tsib-axisib txhijmachining chaw

XYZ linear axis hollow cua txias ntsia hlau tsav

B\C teb ncej DD ncaj tsav kis tau tus mob

Tag nrho kaw lub voj tsis muaj nqi ntsuas qhov system

Main configuration

| No | Yam khoom | Chav tsev | Qty |

| 1. | FH mainframe ntxhia casting | SET | 1 |

| 2. | Siemens ONE tswj qhov system | SET | 1 |

| 3. | Zaub: 21.5 nti kov zaub vaj huam sib luag | SET | 1 |

| 4. | FH tsib-axis multi-function viav vias taub hau (B-axis) | SET | 1 |

| 5. | FH-DGZX-28010/42B2 milling fais spindle (shielded tig muaj nuj nqi) | PC | 1 |

| 6. | X/Y/Z Axis Hollow Cooled Ball Screws | PC | 3 |

| 7. | Mill Direct Tsav Turntable (C-axis) | SET | 1 |

| 8. | B axis RCN8380 29-ntsis absolute encoder | PC | 1 |

| 9. | C axis RCN2580 28-ntsis kiag li encoder | PC | 1 |

| 10. | INA Cov Menyuam Linear Slides | SET | 7 |

| 11. | Spindle dej txias system | SET | 1 |

| 12. | Tshuab nplhaib hom tshuaj tsuag dej | SET | 1 |

| 13. | Tsib-axis taub hau crescent hom dej tsuag, crescent hom tshuab roj | SET | 1 |

| 14. | Pem hauv ntej thiab sab ua hauj lwm qhov rooj kev ruaj ntseg interlock system | SET | 1 |

| 15. | Waterproof ua hauj lwm rau hauv teeb pom kev zoo | PCS | 2 |

| 16. | Chaw nres tsheb Hydraulic | SET | 1 |

| 17. | Centralized pub lubrication ntaus ntawv | SET | 1 |

| 18. | Kev ua haujlwm sab tu rab phom dej thiab phom cua | SET | 1 |

| 19. | Txiav kua system (CTS 25bar) | SET | 1 |

| 20. | Tag nrho cov ntaub ntawv tiv thaiv daim hlau | SET | 1 |

| 21. | Lub thawv ua haujlwm | SET | 1 |

| 22. | Hluav taws xob lub thawv cua txias | SET | 1 |

| 23. | Siemens electronic handwheel | PC | 1 |

| 24. | Ko taw-ua haujlwm spindle riam tso tawm hloov | PC | 1 |

| 25. | Tshuab tri-xim teeb | SET | 1 |

| 26. | 40PCS HSK-A100 cuab yeej magazine thiab servo tsis siv neeg lub cuab yeej hloov qhov system | SET | 1 |

| 27. | X / Y / Z peb-axis tus nqi grating scale | SET | 3 |

| 28. | Kauv Chip dov ntaus ntawv thiab rear Chip Conveyor + Chip tsheb | SET | 1 |

| 29. | Renishaw OMP60 infrared sojntsuam ntaus ntawv | SET | 1 |

| 30. | Renishaw NC4F230 laser cuab tam teeb tsa | SET | 1 |

| 31. | Foundation qib pads thiab foundation bolts | SET | 1 |

| 32. | Technical phau ntawv | SET | 1 |

Parameter

| Qauv | Chav tsev | FH100P |

| Mus ncig | ||

| X axis taug kev | mm | 1000 |

| Y axis taug kev | mm | 1150 |

| Z axis taug kev | mm | 1000 |

| Qhov deb ntawm qhov ntswg spindle mus rau lub rooj ua haujlwm | mm | 160-1160 ib |

| Kab rov tav milling taub hau | mm | 30-1030 Nws |

| Pub / ceev txav ceev | m/min | 40 |

| Pub zog | KN | 10 |

| Rotary rooj (C axis) | ||

| Lub rooj ua haujlwm loj | mm | Ø 1100 |

| Max.table load (mills) | kg | 4000 |

| Milling worktable max ceev | rpm ua | 100 |

| Yam tsawg kawg nkaus lub kaum sab xis | ° | 0.001 ib |

| Rated torque | Nm | 1630 |

| Qhov siab tshaj plaws torque | Nm | 2630 ib |

| CNC viav vias milling taub hau (B axis) | ||

| Lub viav vias ntau yam (0 = Vertical / 180 = Qib) | ° | -15 ~ 180 |

| Ceev ceev thiab pub mis ceev | rpm ua | 50 |

| Yam tsawg kawg nkaus lub kaum sab xis | ° | 0.001 ib |

| Rated torque | Nm | 1050 |

| Qhov siab tshaj plaws torque | Nm | 2130 ib |

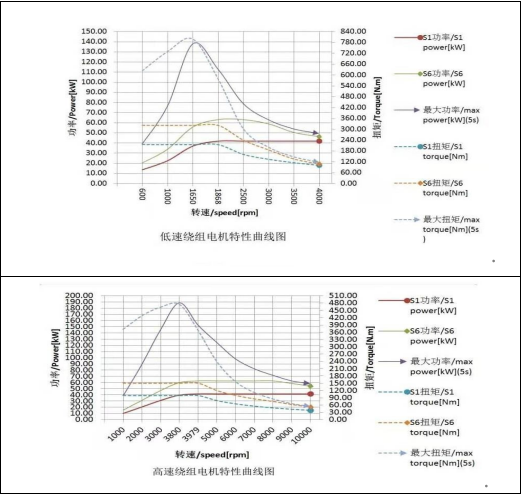

| Spindle (milling thiab tig) | ||

| Spindle ceev | rpm ua | 10000 |

| Spindle zog | Kw | 42/58 ib |

| Spindle torque | Nm | 215/350 ib |

| Spindle taper |

| TSI 100 |

| Tool magazine | ||

| Tool interface |

| TSI 100 |

| Cov cuab yeej magazine muaj peev xwm | PCS | 40 |

| Max.tool diameter/ntev/heev |

| Ø 135/300/12 |

| Tool hloov (Tool to tool) | S | 4 |

| Kev ntsuas ntsuas | ||

| Infrared sojntsuam | Rensishaw OMP60 | |

| Cov cuab yeej kuaj xyuas cov cuab yeej hauv thaj chaw ua haujlwm |

| Rensishaw NC4F230 |

| Txoj hauj lwm raug (ISO230-2 thiab VDI3441) | ||

| X / Y / Z qhov tseeb | mm | 0.006 ib |

| X / Y / Z Rov ua qhov tseeb qhov tseeb | mm | 0.004 ib |

| B/C positioning raug |

| 8" |

| B/C Rov ua qhov tseeb qhov tseeb |

| 4" |

Main Tshuab Specifications | Optimum Rigid Structural Configuration

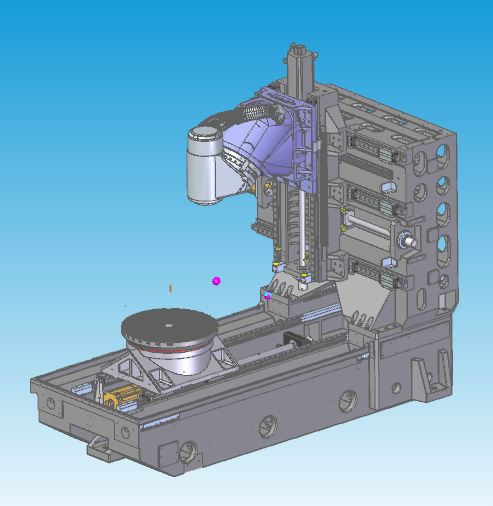

Tsim nta | Qhov zoo tshaj plaws Mechanical Wire Casting Analysis Design

◆ Lub txaj tau txais cov qauv ntxhia tshiab, thiab cov khoom txav txav tau txais Meehanite qib high-qib cam khwb cia hlau

◆ Tempering thiab natural aging kho kom tshem tawm cov kev ntxhov siab sab hauv

◆ Cov txheej txheem ntuj zaus vibration tshem tawm cov khoom siv kev ntxhov siab

◆ Kev tsim ntawm cheeb tsam loj thiab siab-rigidity kem ntawm tag nrho cov phab ntsa tuaj yeem txhim kho qhov rigidity thiab zoo li qub thiab dynamic precision

◆ Peb-axis hollow txias ntsia hlau tsav

Hluav taws xob spindle

Tsim nta

◆ Kev tshawb fawb ywj pheej thiab kev tsim kho thiab tsim khoom raws li cov yam ntxwv ntawm peb lub tshuab.

◆ Lub qhov taper ntawm HSK-A100 yog saws nyob rau hauv tus qauv FH100P.

◆ Lub tshuab cua txias sab nraud yog siv los ua kom txias txias, uas zoo lav rau daim ntawv thov hluav taws xob ntxaiv.

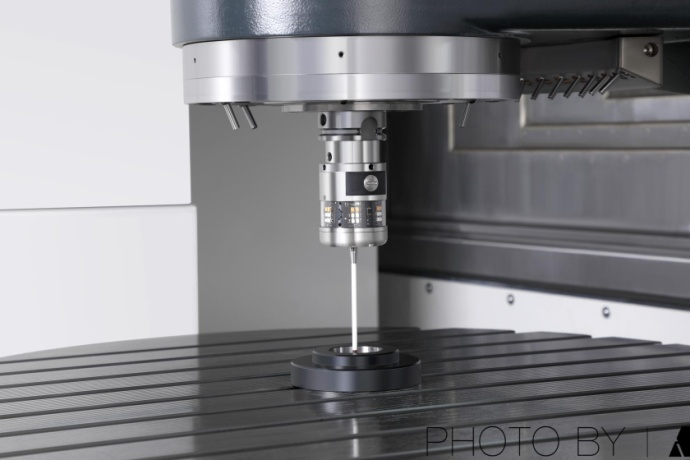

CNC viav vias milling taub hau (B axis)

Tsim nta

◆ Ua-nyob rau hauv DD lub cev muaj zog xoom kis tau tus mob tsis muaj backlash tsim

◆ Cov yam ntxwv ceev ceev

◆ Qhov luv tshaj plaws ntawm qhov ntsuas qhov ntswg ntawm qhov ntxaiv thiab cov qauv kev txhawb nqa taw qhia paub txog qhov siab tshaj plaws ntawm kev txiav.

◆ Loj YRT bearings nce rigidity

◆ Nruab nrog HEIDENHAIN RCN8380 series qhov ntsuas qhov ntsuas qhov ntsuas qhov tseeb, tag nrho cov voj kaw kaw kom ntseeg tau qhov raug zoo tshaj plaws

◆ B-axis txias system tsim los txo cov cua sov hloov

Rotary rooj (C axis)

Tsim nta

◆ Ua-nyob rau hauv DD lub cev muaj zog xoom kis tau tus mob tsis muaj backlash tsim

◆ High acceleration thiab deceleration teb yam ntxwv

◆ Loj YRT bearings nce rigidity

◆ Loj rated tsav torque, qhov chaw thiab ua nrog lub rooj positioning thiab clamping ntaus ntawv

◆ Ua tau raws li ob qhov kev xav tau ntawm kev milling, txo cov khoom ua haujlwm thiab txhim kho cov khoom raug

◆ Nruab nrog HEIDENHAIN high-precision teb encoder ntsuas qhov system, tag nrho kaw-voj tswj kom ntseeg tau qhov raug zoo tshaj plaws

◆ Lub tshuab cua txias tsim los txo cov cua sov hloov

Tus tswj

Kev xaiv nta

◆ Xaiv tus tswj tuav tswj NCU730.3B rau tsib-axis txuas (saib cov lus ua haujlwm kom paub meej txog kev teeb tsa ntawm lub kaw lus)

◆ Nrog RTCP muaj nuj nqi

◆ Xaiv Siemens S120 tsav tsheb nrog 3 lub sij hawm dhau lub peev xwm thiab 1FT series lub cev muaj zog nrog cov yam ntxwv siab

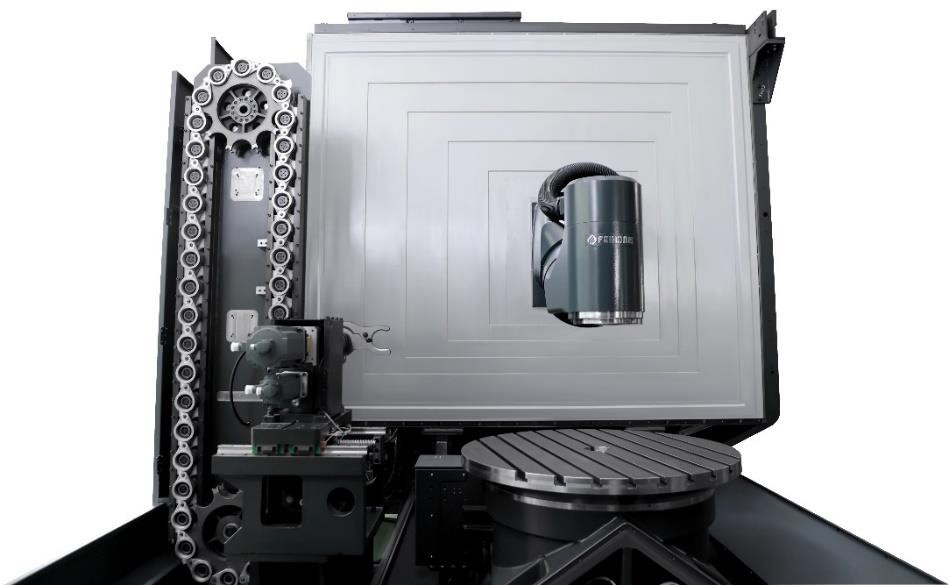

ATC qhov system

Tsim nta

◆ Kev ywj pheej tsim thiab tsim khoom.

◆ Cov cuab yeej xaiv thiab cov cuab yeej hloov pauv siv servo lub cev muaj zog los tswj lub davhlau ya nyob twg, uas ruaj khov thiab raug.

◆ Ua ke nrog cov cuab yeej tswj kev ua haujlwm ntawm Siemens ONE, kev tswj cov cuab yeej siv tau zoo dua.

Liftable cuab tam setter

Tsim nta

◆ Nruab nrog Ransishaw NC4F230 tsis tiv tauj laser cuab tam rau siab dua

◆ Tsis siv neeg cov cuab yeej teeb tsa ntawm lub tshuab, tsis siv neeg hloov tshiab ntawm cov cuab yeej them nyiaj

◆ Cov cuab yeej teeb tsa tuaj yeem raug tsa thiab txo kom txuag tau qhov chaw ntawm qhov chaw ua haujlwm

◆ Tag nrho cov ntaub ntawv hlau tsim tiv thaiv lub cuab yeej setter los ntawm dej thiab hlau filings thaum ua

Infrared sojntsuam

Tsim nta

◆ Nruab nrog Ransishaw OMP60 optical kov sojntsuam

◆ On-machine workpiece alignment thiab loj soj ntsuam, txo cov phau ntawv soj ntsuam yuam kev, txhim kho cov khoom raug thiab ua efficiency

◆ 90% kev txuag nyiaj hauv lub sijhawm pab hauv tshuab

Sab nrauv

Lub npog tsim ntawm FH series tsib-axis milling-tig compound machining chaw ua raws li cov qauv kev nyab xeeb CE. Tag nrho cov ntawv siv ntom ntom hlau tiv thaiv tus neeg teb xov tooj los ntawm kev ua yuam kev los ntawm kev ua yuam kev thaum kev siv cov kua hluav taws xob siab los tiv thaiv cov tshuab hluav taws xob siab los ntawm lub tshuab. Tsuas yog Ntxiv rau daim ntawv ceeb toom, lub qhov rooj ua haujlwm kuj tseem muaj qhov hloov pauv kev nyab xeeb los tiv thaiv kev sib tsoo thaum lub sijhawm ua haujlwm lossis kev saib xyuas. Thiab muaj lub qhov rais peep loj, uas yooj yim rau tus neeg teb xov tooj kom nkag siab txog kev ua haujlwm thiab kev ua haujlwm ntawm lub tshuab.

huv

Siv lub npog npog telescopic thiab cov ntawv hlau tiv thaiv los tiv thaiv cov chips tsim thaum lub sijhawm ua haujlwm, tsis txhob txiav splashes thiab ua rau muaj kev puas tsuaj rau lwm cov txheej txheem.

Teeb pom kev zoo

Qhov chaw ua haujlwm yog nruab nrog ob lub teeb ci LED, thiab lub teeb pom kev zoo ntawm cov teeb pom kev zoo yog khaws cia siab tshaj 800LUX, muab qhov chaw ua haujlwm zoo rau tus neeg teb xov tooj.

Kev khiav hauj lwm

Sab kev ua haujlwm yog nruab nrog lub qhov rooj zawv zawg sib cais, uas muab qhov chaw qhib loj, uas yooj yim rau cov khoom ua haujlwm kom dawb thiab tshem tawm ntawm peb cov lus qhia siv crane.