Tsib-axis Gantry Machining Center GF Series

Nta

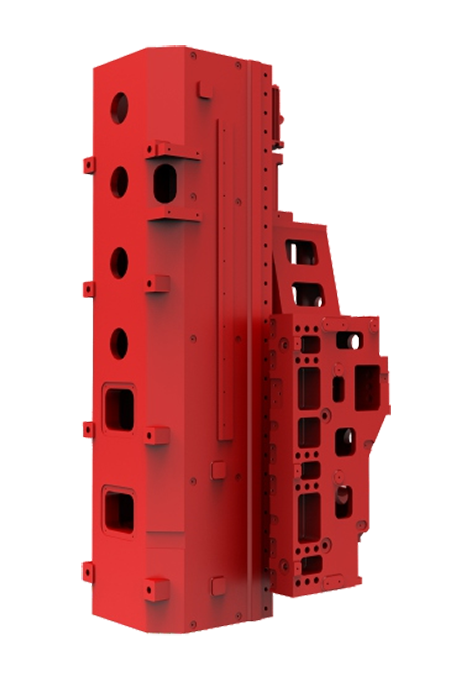

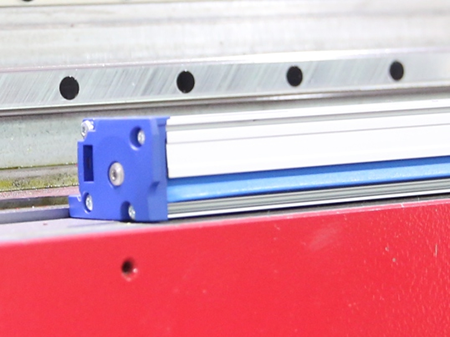

Tilted Tsim Ntawm X-axis

Lub mounting platform qhov siab ntawm qhov sib txawv X-axis linear qhia rails xyuas kom siab rigidity thiab realizes high-speed thiab high-precision positioning

Tshwj xeeb U-shapedSaddleDkos npe

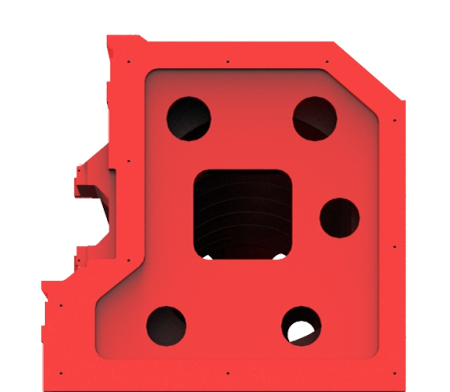

Lub taub hau yog tsim los nrog siab rigidity headstock, uas yog clamped los ntawm U-shaped eeb los ntawm kev qhia rails ntawm ob sab los xyuas kom meej lub siab rigidity ntawm Z-axis extension machining

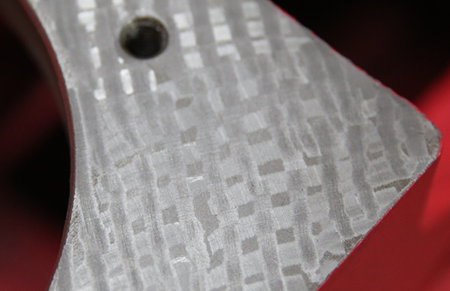

CovJtshuaj pleevSurfaceOf The WqhovMua mobSqauvIs Pkev txiav txim siabShoov

Nws thaj chaw tiv tauj yog ntau tshaj 90% los xyuas kom meej qhov tseeb geometric ntawm tag nrho lub tshuab

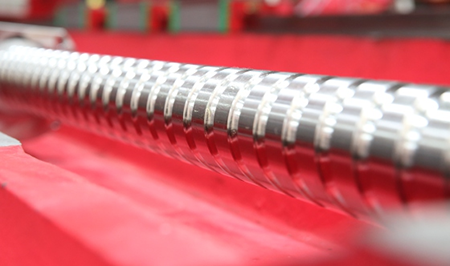

UltraSroojAraug

Cov ntsia hlau pas nrig adopts hom installation ntawmfixed ua ntej nro ntawm ob qho kawg thiab khawb ntawm cov pob qij txha los xyuas kom meej lub siab thiab ultra-ruaj khov precision ntawm lub tshuab cuab yeej nyob rau hauv loj mus ncig.

Kev koom ua keGantryAnd Base

Kem beam integrated tsim, txhim kho lub rigidity ntawm lub tshuab thiab ua stability.

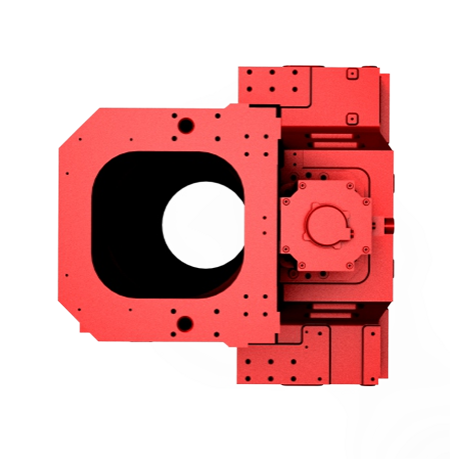

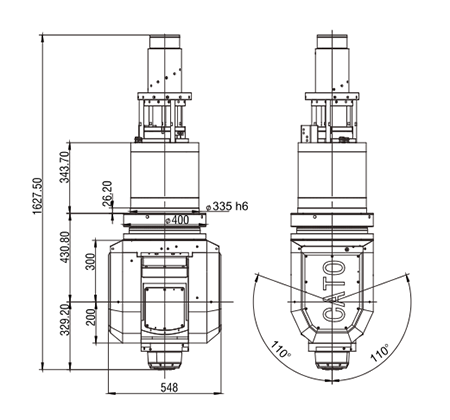

F1 Fork Hom Synchronous Ob-axis Milling Lub Taub Hau

Lub symmetrical cross qauv muaj ntau dua cov qauv rigidity thiab kev vibration suppression dua tib theem qauv.

Lub B / C axis siv lub cev muaj zog tsav ncaj qha thiab cov lus teb hydraulic nres, uas muaj qhov siab dua, xoom rov qab thiab xoom hnav.

Cov dej-txias Circuit Court tsim thiab cov ntxaiv yog nruab nrog lub qhov hluav taws xob hauv nruab nrab raws li tus qauv, uas tuaj yeem cuam tshuam qhov kub thiab txias hloov pauv thiab xyuas kom meej dua.

Okev xav Kev teeb tsa

Kev Tshawb Fawb Txog Kev Tshawb Fawb Hauv Phau Tsom Faj

Cov cuab yeej tshawb nrhiav tau nruab rau hauv cov cuab yeej tsev qiv ntawv, thiab cov txheej txheem tshawb nrhiav thiab cov txheej txheem ua tiav ib txhij, tsis muaj kev cuam tshuam rau kev ua tiav.

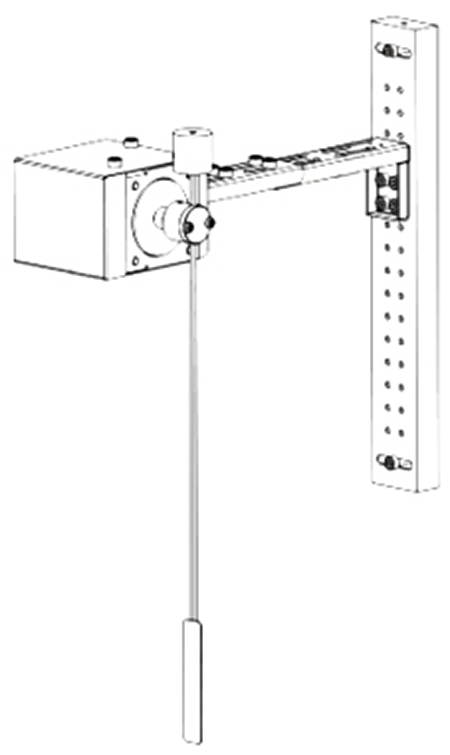

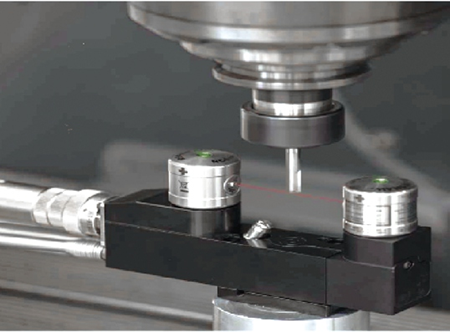

Axialxaiv tau Ntsuas

Lub teeb liab ntsuas cov zis yog cov mem tes digital, uas muaj cov yam ntxwv ntawm kev tshawb pom loj, kev tshawb pom qhov tseeb thiab cov lus teb ceev ceev.

Online Detection System

Rtxhawb kev teeb tsa lub cuab yeej thiab lub sijhawm ua haujlwm sib dhos, thiab txuag 90% lub sijhawm pabcuam.

Reduce cov khoom pov tseg tshwm sim los ntawm kev ua haujlwm tsis raug ntawm cov cuab yeej teeb tsa thiab cov khoom ua haujlwm, thiab txhim kho cov txiaj ntsig.

Laser Tool Setting Instrument

Kev tshawb pom sai thiab raug ntawm cov cuab yeej loj kom ntseeg tau tias siv tau ntev yam tsis hnav

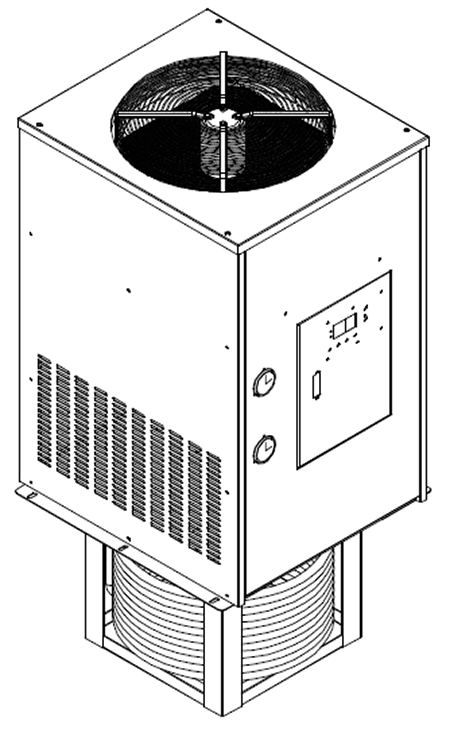

Txiav Cov Cua Txias Txias

Lub thermal hloov ntawm fifixture thiab workpiece tshwm sim los ntawm qhov kub thiab txias ntawm kev txiav flufluid yuav cuam tshuam rau qhov tseeb machining.

Lub kaw lus tuaj yeem ua kom qhov kub nce siab ntawm cov kua dej hauv 3-5 ℃

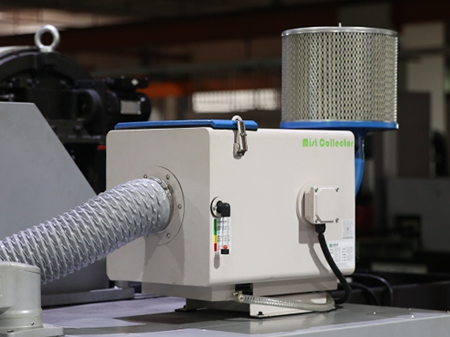

Roj Mist Gathering System

High puri cation tus nqi, ruaj khov ua haujlwm, ntsiag to suab oor.Effectively ltter cov dej-soluble huab cua thiab roj pos huab cua nyob rau hauv lub rhiav thiab purify huab cua heev.

Technical Specifications

| Qhov project | GF2020-5X | GF3020-5X | GF4020-5X | |

| Mus ncig | X / Y / Z axis taug kev | 2000 × 2000 × 800mm | 3000 × 2000 × 800mm | 4000 × 3000 × 1000mm |

| Spindle qhov ntswg rau lub rooj center | 90-890 hli | 80-880 hli | -100-900 hli | |

| Rooj | Rooj loj | 2000 × 1100 hli | 3000 × 1200 hli | 4000 × 2000mm |

| Max. rooj load | 2000 Kg | 2500 kg | 20000 kg | |

| Spindle | Spindle taper | HSK-A63 | HSK-A63 | HSK-A100 |

| Max. spindle ceev | 18 000rmp | 18 000rmp | 8 000rmp | |

| Spindle lub cev muaj zog | 30/33.5KW 1 | 30/33.5KW 1 | 70/75 KW TSI | |

| Spindle motor torque | 72/85 Nm | 72/85 Nm | 350/450 Nm | |

| Pub tus nqi | Ceev ceev ntawm X / Y / Z axis | 36.30.30 Nws | 30/30/30 ib | 15/15/10 |

| Txiav pub | 1-12000 Nws | 1-12000 Nws | 1-10000 | |

| ATC | Tus naj npawb ntawm cov cuab yeej | 24 T | 24 T | 24 T |

| Cov cuab yeej siv ntev tshaj plaws | 400 hli | 400 hli | 400 hli | |

| Qhov siab tshaj plaws lub cuab tam txoj kab uas hla | 120 hli | 120 hli | 250 hli | |

| Qhov siab tshaj plaws qhov hnyav | 8kg ua | 8kg ua | 15kg ua | |

| Tool changetime (tool to tool) | 4.5 S | 4.5 S | 5S | |

| Peb axis | X-axis qhia | 45/4 Roller | 45/5 Roller | 45/4 Roller |

| Y-axis qhia | 55/2 Roller | 55/2 Roller | 65 Roller | |

| Z-axis qhia | 55/3 Cov | 55/3 Cov | 65 Roller | |

| X-axis ntsia hlau | φ50 × 16 | φ63 × 16 | φ80 × 20 | |

| Y-axis ntsia hlau | φ50 × 16 | φ50 × 16 | φ63 × 16 | |

| Z-axis ntsia hlau | φ50 × 12 | φ50 × 12 | φ63 × 16 | |

| Precision | Positioning precision | ± 0.005/300 hli | ± 0.005/300 hli | ± 0.005/300 hli |

| Repeating positioning precision | ± 0.003 / 300 hli ± 0.003 / 300mm | ± 0.003 / 300 hli | ||

| Hwj chim | Lub zog xav tau | Peb theem 380V ± 10%, 50Hz ± 1% Peb-theem 380V ± 10%, 50Hz ± 1% | Peb-theem 380V ± 10%, 50Hz ± 1% | |

| Cua siab | ≥6kg/c ≥6kg/c | ≥6kg / c | ||

| Cua flowrate | ≥0.5mm³ / min ≥0.5mm³ / min | ≥0.5mm³ / min | ||

| Tshuab loj | Tshuab hnyav | 20 T 22 T | 50 t ib | |

Cov txheej txheem txheej txheem

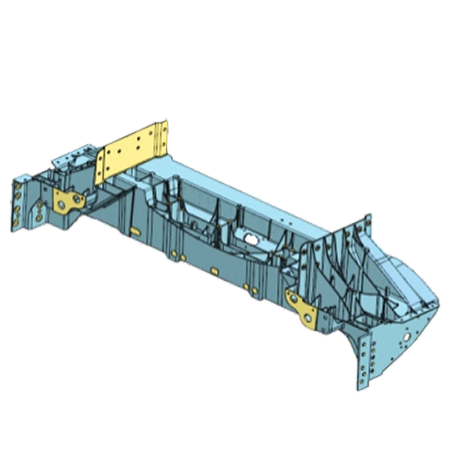

1.TshebMua

SiabProcessingEfficiency

Ib zaug clamping ntawm workpiece, 5-axis ib txhij tswj

Vertical, kab rov tav thiab ntau lub kaum sab xis ua tiav tuaj yeem ua tiav synchronously

SiabMaterialRemovalRnoj

Kev kub ceev, siab zog spindle

High rigidity thiab siab dynamic yam ntxwv ntawm tag nrho cov tshuab qauv

SiabCsivFua edRnoj

XYZ axis kev kub ceev tsav

High rigidity thiab siab dynamic yam ntxwv ntawm tag nrho cov tshuab qauv

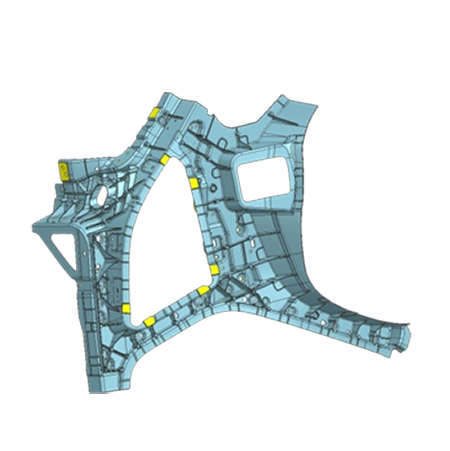

2.AerospaceStsimPkos duab

Zoo heevSurfaceProcessingQuality

Tsib-axis simultaneous txiav daim ntawv thov

High-precision ua muaj peev xwm

Zoo heevShortenProcessingAnd PolishingTyam

Linear tsav tsav

X/Y/Z axis high-speed tsav

SiabPkev txiav txim siab

High-speed, high-power spindle

High rigidity thiab siab stability ntawm tag nrho cov tshuab qauv