E31 CNC Cylindrical Grinder Rau Cutter Cov Cuab Yeej

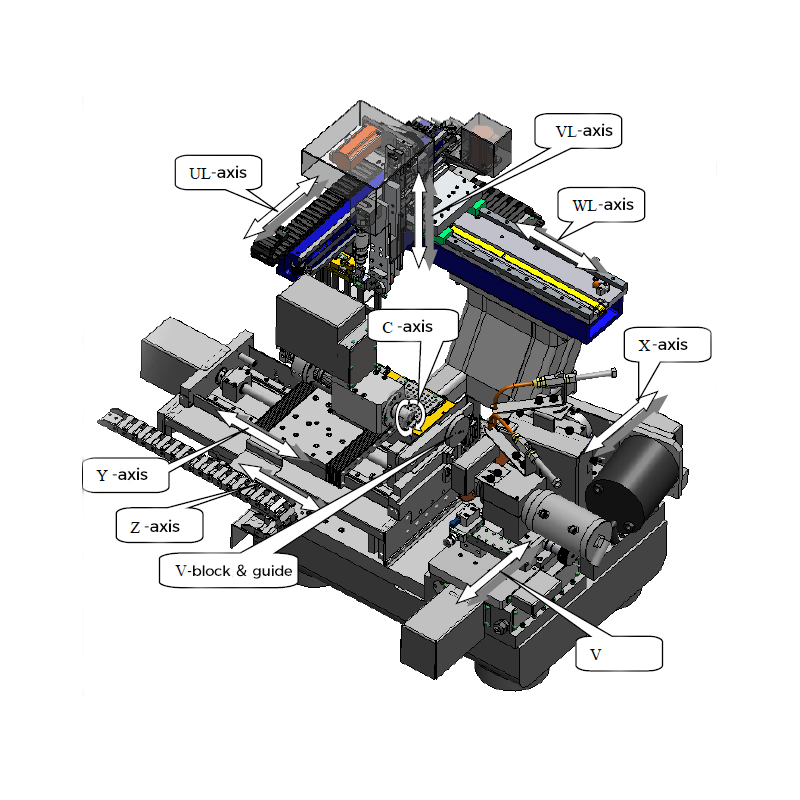

Main qauv daim duab ntawm lub tshuab

Daim ntawv thov Scope

1. Daim ntawv thov ntau yam: milling cutter, laum me ntsis, reamer thiab ntau yam kev ua haujlwm siab.

2. Kev ua ntau yam: txoj kab uas hla ntau yam ntawm cov khoom ua tiav: Φ3~Φ20mm, qhov ntev ntawm cov khoom tiav: 120mm (tsis siv neeg), 330mm (phau ntawv).

3. Cov yam ntxwv ua haujlwm: ib txhij sib tsoo ntawm cov nplua thiab ntxhib sib tsoo ob lub log, ib zaug ua thiab sib sau

Tshuab taw qhia

1. Lub txaj txaj:

2. Sheet hlau ntawm tag nrho lub tshuab: tag nrho lub tshuab muaj ib tug tag nrho cov txheej txheem, thiab lub ntsiab ncej yog cais los ntawm lub sab nrauv cover kom tsis txhob muaj kev co.

3. Tswj qhov system: NEWCON

4. Tsiv qhov chaw: X-axis, V-axis, Z-axis, Y-axis, WL-axis, UL-axis, VL-axis, qhia log mechanism, caj npab mechanism, hysteresis hloov kho mechanism

5. Workpiece spindle: Chuangyun tus kheej ua spindle

6. Sib tsoo spindle: Xiamen Tungsten Tsav

7. Lubrication ntawm tag nrho lub tshuab: roj txiv mis yog tseg rau txhua axis thiab lubricated tsis tu ncua

8. Electronic control unit:

9. Txoj kev pub mis: peb-axis manipulator pub

Technical specifications

| tswj txoj kev | Sab nraud nyees khawm, kov npo | |

| Cov txheej txheem pom | Kov npo, ceeb toom teeb | |

| txoj kev ua kom txias | Roj txias | |

| hloov txoj kev | Hydraulic, pneumatic, servo lub cev muaj zog | |

| fais fab mov | AC 3 × 380V, 50Hz | |

| Lub zog tag nrho | 25 KW | |

| Qhov ntev | 2152 × 1838 × 2614 hli | |

| hnyav tag nrho | 3 050kg | |

| Txias roj siab | 0.6 ~ 0.8MPa | |

| barometric siab | Tag nrho txoj kev siab: 5 ~ 6Bar | |

| Chuck cua siab: 2 ~ 3 Bar | ||

| Kev taw qhia lub log cua siab: 2 ~ 2.5Bar | ||

| Gripper cua txoj kev siab: 1.5 ~ 4Bar | ||

| Caj npab cua siab: 5 ~ 6Bar | ||

| Optical nplai tu huab cua siab: 0.6 ~ 0.7Bar | ||

| Manipulator parameters | ||

| UL axis | Mus ncig | 450 hli |

| Rov ua dua | 0.02 hli | |

| Kev khiav hauj lwm ceev tshaj plaws | 15000mm / min | |

| VL axis | Mus ncig | 100 hli |

| Rov ua dua | 0.02 hli | |

| Kev khiav hauj lwm ceev tshaj plaws | 15000mm / min | |

| WL axis | Mus ncig | 5 40mm |

| Rov ua dua | 0.02 hli | |

| Kev khiav hauj lwm ceev tshaj plaws | 15000mm / min | |

| Kev ua axis parameter | ||

| Z axis | Mus ncig | 100 hli |

| Yam tsawg kawg nkaus daws qhov tseeb | 0.0001 hli | |

| Y axis | Mus ncig | 350 hli |

| Yam tsawg kawg nkaus daws qhov tseeb | 0.0001 hli | |

| X axis | Mus ncig | 35mm ib |

| Yam tsawg kawg nkaus daws qhov tseeb | 0.0001 hli | |

| V axis | Mus ncig | 35mm ib |

| Yam tsawg kawg nkaus daws qhov tseeb | 0.0001 hli | |

| Kev taw qhia log | Kev sib hloov qhov tseeb: | ≤0.010 hli |

| Lub taub hau ua haujlwm (C axis) | Lub cev muaj zog | 1,57 kwv |

| Rotating ceev | ≤2000rpm | |

| Runout raug | ≤0.002 hli | |

| yam tsawg kawg nkaus daws teeb meem | 0.0001° | |

| Rough sib tsoo log spindle | Lub cev muaj zog | 8.5 kWm |

| Rotating ceev | ≤ 5000rpm | |

| Runout raug | ≤0.002 hli | |

| dynamic tshuav nyiaj li cas | ≤G0.4 | |

| Fine sib tsoo log spindle | Lub cev muaj zog | 1.4 KW TSI |

| Rotating ceev | ≤ 7950 rpm | |

| Runout raug | ≤0.002 hli | |

| dynamic tshuav nyiaj li cas | ≤G0.4 | |

| Sib tsoo parameter |

|

|

| Chuck qauv | W 20 | |

| Coarse sib tsoo log txoj kab uas hla | Ø 250 mm | |

| Fine sib tsoo log txoj kab uas hla | Ø 150 mm | |

| Workpiece Shank Txoj kab uas hla | Ø3-Ø12mm (tsis siv neeg) / Ø3-Ø20mm (manual) | |

| Workpiece Sib Tsoo Ntau | Ø 0.08 - Ø 20 mm | |

| workpiece ntev | 120mm (tsis siv neeg) / 350mm (phau ntawv) | |

| Qhov siab tshaj plaws ua qhov ntev ntawm lub workpiece | 330 hli | |

| Processing txheej kab uas hla runout | ≤0.003 hli | |

| Ntev machining raug | ± 0.1 hli | |

| Lub kaum sab xis machining raug | ≤0.3° | |

| Lub ntsej muag raug | ≤Ra0.4 (kev sib tsoo tiav) | |

Standard configuration daim ntawv teev

| 10 | CNC system | NEWC0 N | 1 |

| 20 | servo lub cev muaj zog | NEWC0 N | 8 |

| 30 | server Driver | NEWC0 N | 4 |

| 40 | Kev ua haujlwm vaj huam sib luag / tes log | NEWC0 N | 1 |

| 50 | High precision ua haujlwm lub taub hau module | GESAC | 1 |

| 60 | High precision fais spindle (1.4KW) | GESAC | 1 |

| 70 | High precision lub cev muaj zog (7.1KW) | GESAC | 1 |

| 80 | High Precision Mechanical Spindle | GESAC | 1 |

| 90 | Precision rail | Schneeberger | 10 |

| 100 | Precision Hla Cov Menyuam Linear Txoj Kev | Schneeberger | 4 |

| 110 | Precision Pob Ntsia Hlau | NSK | 4 |

| 120 | Kev ua haujlwm thiab kev ua haujlwm simulation software (tus qauv sib txawv, kheej kheej, thiab lwm yam) | GESAC | 1 |

| 130 | Inverter | GESAC | 1 |

| 140 | Inverter | GESAC | 1 |

| 150 | kov npo | 19 ELO | 1 |

| 160 | Tshuab cuab tam kev ruaj ntseg qhov rooj xauv khoom | Jinzhong | 1 |

| 170 | sensor | Baumer | 3 |

| 180 | flow sensor | Yifumen | 1 |

| 190 | Cov khoom siv hluav taws xob | Schneider | 1 |

| 200 | Pneumatic Cheebtsam | CKD | 1 |

| 210 | Hlau thiab Cable | ComCab | 1 |

| 220 | Rack cua txias | GESAC | 1 |

| 230 | Precision siab log Ø92x8 | GESAC | 1 |

| 240 | Precision siab log Ø92x15 | GESAC | 1 |

| 250 | Chuck W20 D4 | GESAC | 1 |

| 260 | Standard tais D4 | GESAC | 3 |

| 260 | High-precision txuam V-block (3-6) * 10 | GESAC | 1 |

| 280 | High precision sib tsoo log flange (ceev hloov hom) | GESAC | 2 |

| 290 | Tag nrho cov txheej txheem manipulator ntiv tes | GESAC | 1 |

Tshuab yam ntxwv

8 CNC axes, 5 CNC axes yog siv rau hauv qhov chaw ua haujlwm, uas tuaj yeem paub tsis siv neeg thauj khoom thiab tshem tawm, batch unmanned ntau lawm

Machining raug thiab efficiency ntawm cov cuab yeej siv tshuab

1. Lub radial runout ntawm lub workpiece yog nyob rau hauv 0.003mm;

2. Qhov tseeb ntawm qhov loj 2.0 yog tswj tsis pub dhau ± 0.005mm;

3. Lub roundness ntawm lub workpiece yog nyob rau hauv 0.003mm;

4. Nto roughness