Ob chav ntxaiv CNC tshuab dhos 208 series

Khoom Configuration

Taw qhia

TurretDkos npePkev ua haujlwm

Kev sib xyaw ua ke zoo Y-axis qauv yog nruj heev, hnyav-lub luag haujlwm, thiab muaj kev ua tau zoo dua li kev cuam tshuam Y-axis.

· smoother thiab smoother dav hlau contour ua

· Yooj yim rau cov txheej txheem sib xyaw nkhaus thiab contours

Piv nrog rau "interpolation Y", "zoo Y" muaj qhov pom tseeb zoo hauv dav hlau milling. Qhov "zoo Y" Y-axis txav yog perpendicular rau X-axis thiab yog ib leeg-axis txav. Qhov "interpolation Y" Y-axis txav yog los cuam tshuam txoj kab ncaj nraim los ntawm kev txav ib txhij ntawm X-axis thiab Y-axis. Piv nrog rau "zoo Y" rau qhov flatness ntawm lub dav hlau milling, "zoo Y" axis ua yog pom tseeb ci thiab du.

Ncaj qhaDdejSynchronousEhluav taws xobSpindle

High rigidity, siab torque, ntau dua efficiency, zoo tiav, ntau meej indexing.

Tag nrho cov tshuab loj yog ua los ntawm cov hlau cam HT300 nrog lub zog nqus nqus nqus.

Cov yam ntxwv ntawm cov cuab yeej siv tshuab nrog ncaj-tsav hluav taws xob spindles

●Magnetic nplhaib incremental encoder (sine thiab cosine) qhov tseeb qhov tseeb: 20 arc vib nas this,

C-axis indexing raug: 40 arc vib nas this

● Ceev pib-nres cov lus teb ceev, txuag lub sijhawm siv lub tshuab thiab txhim kho cov peev txheej ntau lawm

● Kev txiav me me, txuag hluav taws xob thiab txuag hluav taws xob, kev tiv thaiv zoo dua ntawm cov cuab yeej siv tshuab thiab kev pab lub neej ntev

● Ua tau zoo tshem tawm cov ntxaiv kev vibration, zoo sib npaug, ua tiav zoo, thiab txhim kho qhov ua tiav ntawm workpieces

(Qhov zoo ntawm kev tig es tsis txhob sib tsoo, tawv tig zoo li, nto roughness Ra 0.2μm)

· Lub tshuab spindle yog nruab nrog lub tshuab ua kom txias kom tsis txhob muaj kev cuam tshuam ntawm thermal hloov thiab xyuas kom meej tias lub spindle tseem ua haujlwm ntawm qhov kub thiab txias.

(Lub qhov ntswg kawg qhov tseeb yog nyob rau hauv 0.002mm, kom ntseeg tau qhov tseeb ntau dua)

· rear-mounted ncaj-tsav synchronous spindle, yooj yim dua installation thiab txij nkawm

· A2-5: 7016AC-pem hauv ntej ob rear ob

· A2-6: pem hauv ntej NN3020+100BAR10S, rear NN3018

A2-8: pem hauv ntej NN3024 + BT022B * 2, rear NN3022

Hnyav-DutyCastIronBaseAnd Ccov omponents

Tag nrho cov castings yog optimized siv finite element tsom xam (FEA) kom txo tau distortion thiab lift-off shock absorption peev. Cov castings ntawm cov koob loj ntawm cov tshuab dhos yog ntxiv nrog cov tav los txhim kho rigidity thiab thermal stability. Compact thiab symmetrical headstock thiab tailstock castings ntxiv rigidity thiab xyuas kom meej qhov chaw siab thiab repeatability.

Technical Specifications

| Yam khoom | Lub npe | Chav tsev | 208 MAS | 208 SIB |

| Mus ncig | Max. txaj rotation txoj kab uas hla | mm | Φ680 | Φ700 |

| Max. machining txoj kab uas hla | mm | Φ370 | Φ300 | |

| Max. rotation txoj kab uas hla ntawm cov cuab yeej tuav | mm | Φ300 | Φ300 | |

| Max. ua qhov ntev | mm | 420 | 400 | |

| Kev ncua deb ntawm ob lub chaw | mm | - | - | |

| Spindle Lub tog raj kheej Chuck | Spindle qhov ntswg | ASA | A2-6 | A2-6 |

| Hydraulic lub tog raj kheej / chuck | Ntiv | 8'' | 8'' | |

| Spindle los ntawm lub qhov taub | mm | Φ79/66 ib | Φ79/66 ib | |

| Max. pas nrig los ntawm lub qhov taub | mm | Φ65/52 ib | Φ65/52 ib | |

| Spindle Max. ceev | rpm ua | 4300 ib | 4300 ib | |

| Spindle lub cev muaj zog | kw | 18/22 | 18/22 | |

| Spindle motor torque | Nm | 91-227 : kuv | 91-227 : kuv | |

| Sub-Spindle Lub tog raj kheej Chuck | Sub-Spindle qhov ntswg | ASA | A2-5 | A2-5 |

| Sub-Hydraulic lub tog raj kheej / chuck | Ntiv | 6” | 6” | |

| Sub-Spindle los ntawm lub qhov taub | mm | Φ56 | Φ56 | |

| Sub-Max. pas nrig los ntawm lub qhov taub | mm | Φ46 | Φ46 | |

| Sub-Spindle Max. ceev | rpm ua | 5500 | 5500 | |

| Sub-Spindle lub cev muaj zog | kw | 17.5 Nws | 17.5 Nws | |

| X/ZN/SAxisFua edParameters | X lub cev muaj zog | kw | 2.5 | 2.5 |

| Y lub cev muaj zog | kw | - | 1.2 | |

| Z lub cev muaj zog | kw | 2.5 | 2.5 | |

| Slub cev muaj zog | Kw | 1.2 | 1.2 | |

| Xaxis taug kev | mm | 236 | 204 | |

| Yaxis taug kev | mm | - | 100±50 | |

| Zaxis taug kev | mm | 510 | 492 ib | |

| X / Z axis rail specifications | spec | 35 rub | 35 rub | |

| Y axis rail specifications | spec | 25 yob | 25 yob | |

| S axis taug kev | mm | 600 | 600 | |

| Xaxis ceev txav | mm / min | 20 | 20 | |

| Zaxis ceev txav | mm / min | 20 | 20 | |

| Yaxis ceev txav | mm / min | - | 8 | |

| Saxis ceev txav | mm / min | 24 | 24 | |

| Servo zog TurretParameters | Lub zog turret hom | / | BMT55 | BMT55 |

| Chaw nres tsheb cuab yeej | / | 12 T | 12 T | |

| M lub cev muaj zog | kw | 5.5 | 5.5 | |

| M axis lub cev muaj zog torque | Nm | 35 | 35 | |

| Lub cev muaj zog Max. ceev | rpm ua | 6000 | 6000 | |

| Outer diameter tool tuav specifications | mm | 25 * 25 | 25 * 25 | |

| Inner diameter tool tuav specifications | mm | Φ40 | Φ40 | |

| Cov cuab yeej nyob ib sab hloov lub sijhawm | sec | 0.15 | 0.15 | |

| Positioning raug | / | ± 2 " | ± 2 " | |

| Rov ua dua qhov tseeb | / | ± 1 " | ± 1 " | |

| TailstockParameters | Programmable hydraulic tailstock | / | - | - |

| Tailstock Max. taug kev | mm | - |

| |

| Lub tes tsho txoj kab uas hla | mm | - |

| |

| Lub tes tsho mus ncig | mm | - |

| |

| Lub tes tsho taper | / | - |

| |

| Qhov ntev | Tag nrho qhov ntev | m | 2800 * 2100 * 1800 hli | 2700 * 2400 *2000 |

| Tshuab hnyav approx. | kg | 5900 ib | 5300 ib | |

| Lwm yam | Txiav kua tank ntim | L | 150 | 150 |

| Txias dej twj tso kua mis zog | kw | 0.75 ib | 0.75 ib | |

| Hydraulic unit box ntim | L | 40 | 40 | |

| Hydraulic roj twj tso kua mis lub cev muaj zog | kw | 1.5 | 1.5 | |

| Lubricating roj tank ntim | L | 2 | 2 | |

| Tsis siv neeg lubrication twj tso kua mis lub cev muaj zog | kw | 50 | 50 |

Configuration Taw Qhia

Yooj yim duaTo Use And MorePmuaj nuj nqis

● Kev tsim kho kom zoo dua qub

● Nruab nrog kuv HMI

● Nruab nrog FANUC qhov tseeb CNC thiab servo tshuab

●Standardized nrog tus kheej muaj nuj nqi

●Expanded nco muaj peev xwm

Yooj yimOf Use

Tiv thaiv kom tsis txhob muaj lub tshuab downtime los ntawm kev tiv thaiv kev saib xyuas

● nplua nuj ua txhaum kev twv ua ntej ua haujlwm

Yooj yim nrhiav qhov chaw txhaum thiab txo lub sijhawm rov qab los

● Kev kuaj mob / kev saib xyuas ua haujlwm

Kev ua haujlwm siab

Luv luvCycleTyam

● High-efficiency processing technology

Ua tiav kev ua haujlwm zoo

Surface fine processing technology

● Kev kuaj mob / tu muaj nuj nqi

SiabOkev ua txhaumRnoj

Ib txwm txhawb nqa ntau yam haujlwm ntawm qhov chaw ua haujlwm

●FANUC

Tus kheejScreenIs EasierTo Use

● Txheem tus kheej muaj nuj nqi

Initiatives nyob rau hauv lub teb ntawm IoT

● Kev txhawb nqa rau ntau yam kev sib txuas hauv chaw

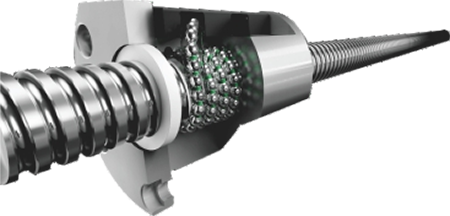

THKBtag nrhoSneeg coob

· C3 qib, siv high-precision pob ntsia hlau, nrog txiv ntseej pre-loading thiab ntsia hlau pre-tensioning kev kho mob ua ntej tshem tawm backlash thiab kub nce elongation, qhia zoo heev positioning thiab repeatability raug.

· Servo lub cev muaj zog tsav ncaj qha los txo qhov yuam kev rov qab.

THKRollerLinearGuide ua

· P qib ultra-siab rigidity SRG precision qib, linear qhia xoom clearance, arc txiav, bevel txiav, nto zoo nkauj kuj zoo ib yam. Haum rau kev ua haujlwm siab ceev, zoo heev txo cov tsav tsheb horsepower xav tau rau cov cuab yeej siv tshuab.

· Rolling es tsis txhob zawv zawg, kev sib txhuam me me, cov lus teb rhiab heev, qhov tseeb ntawm qhov chaw siab. Nws muaj peev xwm dais lub load nyob rau hauv lub tsiv mus nyob rau tib lub sij hawm, thiab txoj kev sib cuag nto yog tseem nyob rau hauv multi-point sib cuag thaum lub sij hawm load, thiab txiav rigidity yuav tsis raug txo.

· Yooj yim sib sau ua ke, muaj zog sib hloov, thiab yooj yim lubrication qauv; tus nqi hnav tsawg heev thiab kev pabcuam lub neej ntev.

SKFBpob ntseg /Oib ilingMua mob

· Tsis siv neeg lubricator ua tau raws li qhov xav tau ntawm ntau daim ntawv thov, haum rau ntau yam kev ua haujlwm, cov khoom siv txhim khu kev qha, siv tau yooj yim.

· Ua tau raws li cov kev xav tau ntawm cov kabmob lubrication nyob rau hauv qhov kub thiab txias, muaj zog vibration thiab txaus ntshai ib puag ncig.

Txhua lub lubrication point siv lub volumetric proportional distributor los tswj lub lubrication tus nqi, thiab lub tshuab tuaj yeem tswj tau los ntawm PLC kom muab cov roj kom raug.