CNC Ob chav spindle tig Center 150MS Series

Khoom Configuration

Qhia

1. Txais kev tsav ncaj qha synchronous hluav taws xob spindle ntaus ntawv: magnetic nplhaib incremental encoder (sine thiab cosine) qhov tseeb qhov tseeb: 20 arc vib nas this, C-axis indexing raug: 40 arc vib nas this. ① Ua tau zoo tshem tawm ntxaiv kev co, thiab qhov qhov ntswg deflection qhov tseeb yog nyob rau hauv 0.002MM. Txhim kho qhov ua tiav ntawm qhov chaw ua haujlwm, ② txais yuav lub rotor rear-mounted, uas ua rau kev txhim kho thiab kev txij nkawm sai dua, ③ lub spindle lub cev muaj zog yog nruab nrog lub tshuab cua txias los tiv thaiv kev cuam tshuam ntawm thermal hloov thiab ua kom lub zog ua haujlwm tsis tu ncua ntawm spindle. Lub tshuab spindle tau dhau los ua qhov ntsuas qhov sib npaug nruj. Nws txoj kev tuav tau zoo, kev nruj nruj thiab kev ua haujlwm siab ua kom lub tshuab tag nrho tsis yog ua kom tiav xwb, tab sis kuj ua cov machining ntxhib thiab hnyav txiav rau cov neeg siv. Nws yog tshwj xeeb tshaj yog haum rau huab hwm coj ntau lawm ntawm complex duab thiab siab smoothness. khoom.

2. High rigidity integrated tsim servo lub zog turret. Nws pab lub servo turret qhov ceev thiab raug lub cuab yeej hloov kev ua tau zoo, thiab thaum ua ke nrog lub zog milling ntawm lub siab ceev fais fab axis, nws ua tiav zoo heev tig thiab milling ua ke ua ke muaj peev xwm. Cov cuab yeej tuav tau nruab nrog lub siab-rigidity BMT installation interface, thiab lub zog xa hluav taws xob yog tsav los ntawm servo spindle motor.

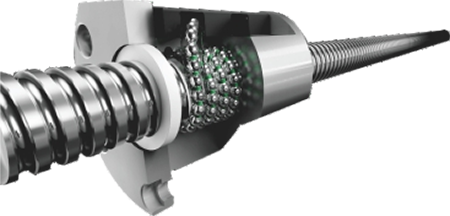

3. Cov cuab yeej siv lub tshuab yog nruab nrog cov kab qhia kev sib tw thiab precision hauv av pob ntsia hlau los xyuas kom meej qhov zoo tshaj plaws thiab kav ntev. Txhua axis txais kev hloov pauv ncaj qha axis qauv thiab ob txoj kev thauj tog rau nkoj ua ntej relay, uas tuaj yeem txo cov thermal hloov pauv thiab ua kom muaj txiaj ntsig zoo. Lub high-rigidity, loj-loj, hnyav-duty linear slide rails tswj tsis tu ncua qhov tseeb thaum lub tshuab raug cuam tshuam, thiab qhov kev hloov pauv yog du thiab tsis tshua muaj suab nrov, uas tuaj yeem ua rau lub neej ua haujlwm ntev.

4. Lub tshuab no muab cov neeg siv ua tiav hydraulic thiab lubrication system, siv cov twj hydraulic zoo, hydraulic li qub thiab lwm yam khoom kom txo tau qhov tsis ua hauj lwm zoo. Lub tshuab hydraulic thiab lubrication yog tsim los kom yooj yim thiab txhim khu kev qha. Lub tshuab cuab yeej txais cov khoom siv nruab nrab ntawm qhov tsis siv neeg lubrication.

5. Nws txais Taiwan teb lub tog raj kheej thiab xaiv tsis siv neeg nti tshem tawm cov cuab yeej. Cov kev xaiv tau muab faib ua kab hauv qab thiab sab kab, uas tuaj yeem txo qis kev siv zog ntawm tus neeg teb xov tooj thiab ua tiav kev nyab xeeb thiab ua haujlwm tau zoo. Cov khoom siv ua haujlwm saum toj no tuaj yeem tsim txhua yam los tswj, thiab tsim nrog cov roj-dej sib cais thiab hlau txiav cov khoom siv lim. Nyob rau tib lub sijhawm, ntau yam tshwj xeeb fixtures tuaj yeem tsim thiab ntsia raws li cov kev cai tshwj xeeb ntawm cov neeg siv.

Technical Specifications

| Iyam Model | Lub npe | Chav tsev | 150 MASY- II | 150 MASY- III | 150 MAS-II | 150 MAS-III |

| Mus ncig | Max. txaj rotation txoj kab uas hla | mm | Ф380 ib | Ф380 ib | Ф380 ib | Ф380 ib |

| Max. ua txoj kab uas hla | mm | Ф100 | Ф100 | Ф100 | Ф100 | |

| Max. ua txoj kab uas hla ntawm lub cuab yeej tuav | mm | Ф160 ib | Ф160 ib | Ф160 ib | Ф160 ib | |

| Max. ua qhov ntev | mm | 150 | 150 | 150 | 150 | |

| Spindle Lub tog raj kheej Chuck | Spindle qhov ntswg | / | A2-5 | A2-5 | A2-5 | A2-5 |

| Max.ceev ntawm spindle | mm | 5500 | 5500 | 5500 | 5500 | |

| Spindle hydraulic lub tog raj kheej / colletHydraulic Lub tog raj kheej / Chuck | rpm ua | 6" | 6" | 6" | 6" | |

| Spindle qhov diameter Spindle qhov diameter | kw | f56 ua | f56 ua | f56 ua | f56 ua | |

| Max.bar qhov taub ntawm spindle Bar txoj kab uas hla | Nm | Ф45 ib | Ф45 ib | Ф45 ib | Ф45 ib | |

| Spindle lub cev muaj zog | / | 17.5 Nws | 17.5 Nws | 17.5 Nws | 17.5 Nws | |

| Spindle lub cev muaj zog |

| 62-125 : kuv | 62-125 : kuv | 62-125 : kuv | 62-125 : kuv | |

| Sub spindle Chuck | Sub-spindle qhov ntswg | / | A2-4 | A2-4 | A2-4 | A2-4 |

| Max.ceev ntawm sub-spindle | mm | 6000 | 6000 | 6000 | 6000 | |

| Sub-spindle hydraulic lub tog raj kheej / collet H | rpm ua | 5" | 5" | 5" | 5" | |

| Sub-spindle los ntawm lub qhov taub | Nm | Ф46 | Ф46 | Ф46 | Ф46 | |

| Max.bar qhov txoj kab uas hla ntawm sub-spindle | kw | Ф32 | Ф32 | Ф32 | Ф32 | |

| Direct tsav hluav taws xob spindle zog | / | 11 | 11 | 11 | 11 | |

| Spindle direct tsav lub cev muaj zog torque |

| 27-66 : kuv | 27-66 : kuv | 27-66 : kuv | 27-66 : kuv | |

| X1/Z1/Y/X2/Z2 axis pub parameter | X1 / Z1 / Y lub cev muaj zog | kw | 1.8/1.2/1.2 | 1.8/1.2/1.2 | 1.8/1.2 | 1.8/1.2 |

| X2 / Z2 lub cev muaj zog | mm | 1.2 / 1.2 | 1.2 / 1.2 | 1.2 / 1.2 | 1.2 / 1.2 | |

| X1 / Z1 axis taug kev | mm | 135/370 ib | 135/370 ib | 135/370 ib | 135/370 ib | |

| X2 / Z2 axis taug kev | hli/min | 215/400 ib | 215/400 ib | 215/400 ib | 215/400 ib | |

| X / Z / / Y / S axis nrawm nrawm | mm | 30/30/6/30 ib | 30/30/6/30 ib | 30/30/30 ib | 30/30/30 ib | |

| X1 / Z1 swb rail hom | mm | Cov menyuam35/35 ib | Cov menyuam35/35 ib | Cov menyuam35/35 ib | Cov menyuam35/35 ib | |

| X2 / Z2 swb rail hom | mm | Cov menyuam30/30 ib | Cov menyuam30/30 ib | Cov menyuam30/30 ib | Cov menyuam30/30 ib | |

| Servo tsav Cutter qhov ntsuas | Turret hom | pcs | BMT45-12T | BMT45-12T | BMT45-12T | BMT45-12T |

| Lub zog turret | Kw/Nm | 2.2/26 Nm | 2.2/26 Nm | 2.2/26 Nm | 2.2/26 Nm | |

| Y axis taug kev | mm | 80(± 40) | 80(± 40) |

| 6000 ES 20 | |

| Max.ceev ntawm tsav lub cuab yeej tuav | rpm ua | 6000 ES 20 | 6000 ES 20 | 6000 ES 20 | 20 x 20 | |

| Sab nraum txoj kab uas hla cuab tam tuav specifications | mm | 20 x 20 | 20 x 20 | 20 x 20 | Ф32 ib | |

| Inner diameter tool tuav specifications | mm | Ф32 ib | Ф32 ib | Ф32 ib | 0.15 | |

| Cov cuab yeej nyob ib sab hloov lub sijhawm | sec | 0.15 | 0.15 | 0.15 | BMT40-8T | |

| Servo zog Turret parameters | Lub zog turret hom | / | NC8 T | BMT40-8T | NC8 T | 2.2/26 Nm |

| Outer diameter tool tuav specifications | mm | 25 x 25 | 20 x 20 | 25 x 25 | 6000 ES 20 | |

| Inner diameter tool tuav specifications | mm | Ф32 | Ф32 ib | Ф32 | 20 x 20 | |

| Cov cuab yeej nyob ib sab hloov lub sijhawm | sec | 0.15 | 0.15 | 0.15 | Ф25 | |

| Qhov ntev | Thaj chaw nyob Approx. | mm | 2.2 x 2.1 x 1.7 | 2.2 x 2.1 x 1.7 | 2.2 x 2.1 x 1.7 | 0.15 |

| Tshuab hnyav Approx. | kg | 3500 | 3500 | 3200 | 2.2 x 2.1 x 1.7 | |

| Lwm yam | Txiav kua tank ntim | L | 180 | 180 | 180 | 3500 |

| Hydraulic unit box ntim | L | 40 | 40 | 40 | 180 | |

| Hydraulic roj twj tso kua mis lub cev muaj zog | kw | 1.5 | 1.5 | 1.5 | 40 | |

| Lubricating roj tank ntim | L | 2 | 2 | 2 | 1.5 | |

| Tsis siv neeg lubrication twj tso kua mis lub cev muaj zog | W | 50 | 50 | 50 | 2 | |

| Txias dej twj tso kua mis zog | W | 750 | 750 | 750 | 50 |

Configuration Nta

Yooj yim duaTo Use And MorePmuaj nuj nqis

● Kev tsim kho kom zoo dua qub

● Nruab nrog kuv HMI

● Nruab nrog FANUC qhov tseeb CNC thiab servo tshuab

●Standardized nrog tus kheej muaj nuj nqi

●Expanded nco muaj peev xwm

Yooj yimOf Use

Tiv thaiv kom tsis txhob muaj lub tshuab downtime los ntawm kev tiv thaiv kev saib xyuas

● nplua nuj ua txhaum kev twv ua ntej ua haujlwm

Yooj yim nrhiav qhov chaw txhaum thiab txo lub sijhawm rov qab los

● Kev kuaj mob / kev saib xyuas ua haujlwm

Kev ua haujlwm siab

Luv luvCycleTyam

● High-efficiency processing technology

Ua tiav kev ua haujlwm zoo

Surface fine processing technology

● Kev kuaj mob / tu muaj nuj nqi

SiabOkev ua txhaumRnoj

Ib txwm txhawb nqa ntau yam haujlwm ntawm qhov chaw ua haujlwm

●FANUC

Tus kheejScreenIs EasierTo Use

● Txheem tus kheej muaj nuj nqi

Initiatives nyob rau hauv lub teb ntawm IoT

● Kev txhawb nqa rau ntau yam kev sib txuas hauv chaw

THKBtag nrhoSneeg coob

· C3 qib, siv high-precision pob ntsia hlau, nrog txiv ntseej pre-loading thiab ntsia hlau pre-tensioning kev kho mob ua ntej tshem tawm backlash thiab kub nce elongation, qhia zoo heev positioning thiab repeatability raug.

· Servo lub cev muaj zog tsav ncaj qha los txo qhov yuam kev rov qab.

THKRollerLinearGuide ua

· P qib ultra-siab rigidity SRG precision qib, linear qhia xoom clearance, arc txiav, bevel txiav, nto zoo nkauj kuj zoo ib yam. Haum rau kev ua haujlwm siab ceev, zoo heev txo cov tsav tsheb horsepower xav tau rau cov cuab yeej siv tshuab.

· Rolling es tsis txhob zawv zawg, kev sib txhuam me me, cov lus teb rhiab heev, qhov tseeb ntawm qhov chaw siab. Nws muaj peev xwm dais lub load nyob rau hauv lub tsiv mus nyob rau tib lub sij hawm, thiab txoj kev sib cuag nto yog tseem nyob rau hauv multi-point sib cuag thaum lub sij hawm load, thiab txiav rigidity yuav tsis raug txo.

· Yooj yim sib sau ua ke, muaj zog sib hloov, thiab yooj yim lubrication qauv; tus nqi hnav tsawg heev thiab kev pabcuam lub neej ntev.

SKFBpob ntseg /Oib ilingMua mob

· Tsis siv neeg lubricator ua tau raws li qhov xav tau ntawm ntau daim ntawv thov, haum rau ntau yam kev ua haujlwm, cov khoom siv txhim khu kev qha, siv tau yooj yim.

· Ua tau raws li cov kev xav tau ntawm cov kabmob lubrication nyob rau hauv qhov kub thiab txias, muaj zog vibration thiab txaus ntshai ib puag ncig.

Txhua lub lubrication point siv lub volumetric proportional distributor los tswj lub lubrication tus nqi, thiab lub tshuab tuaj yeem tswj tau los ntawm PLC kom muab cov roj kom raug.