Zoo tshaj-muag Tuam Tshoj Precision CNC Yeeb Nkab Threading Tshuab dhos tshuab

Peb tsom ntsoov rau yuav tsum tau sib sau ua ke thiab txhim kho qhov zoo thiab kho cov khoom tam sim no, nyob rau hauv lub sijhawm tas li tsim cov khoom tshiab kom tau raws li cov neeg siv khoom tshwj xeeb 'yuav tsum tau muag zoo tshaj plaws Tuam Tshoj Precision CNC Yeeb Nkab Threading Tshuab dhos tshuab, Peb tsom rau kev tsim tus kheej hom thiab hauv ua ke nrog ntau yam kev paub dhau los thiab cov khoom siv thawj-chav kawm. Peb cov khoom koj tsim nyog muaj.

Peb tsom ntsoov rau yuav tsum sib sau ua ke thiab txhim kho qhov zoo thiab kho cov khoom tam sim no, nyob rau hauv lub sijhawm tas li tsim cov khoom tshiab kom tau raws li cov neeg siv khoom tshwj xeeb 'xav tau rauTuam Tshoj CNC Roj Lub Tebchaws Tshuab dhos, CNC Roj yeeb nkab tshuab dhos, Peb zoo siab tos txais koj tuaj xyuas peb lub tuam txhab thiab lub Hoobkas. Nws kuj yog ib qho yooj yim mus xyuas peb lub vev xaib. Peb pab neeg muag khoom yuav muab kev pabcuam zoo tshaj rau koj. Yog tias koj xav paub ntau ntxiv, thov hu rau peb ntawm E-mail lossis xov tooj. Peb vam thiab cia siab tias yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam mus sij hawm ntev nrog koj los ntawm lub sijhawm no, raws li kev sib luag, kev sib raug zoo los ntawm tam sim no mus rau yav tom ntej.

Tshuab Nta

1. Qhov no cov pa yeeb nkab threading tshuab dhos yog ib tug tshiab tsim.

2. Lub txaj yog ib qho tshwj xeeb ntawm peb-txheej phab ntsa qauv, thiab cov phab ntsa tom qab yog teem nrog txoj kab nqes 12 °. Cov lus qhia rail dav ntawm lub txaj yog 550mm. Nws yog super-suab quenched thiab precision grounded los xyuas kom meej qhov tseeb thiab kev pab lub neej ntawm lub tshuab.

3. Tag nrho cov iav kem hom spindle chav tsev, headstock lub thawv yog tag nrho cov qauv casting, es tsis yog lub lev heightening thaiv.

4. Daim ntawv thov ntawm quenching precision sib tsoo iav thiab cov bearings zoo ua kom lub tshuab suab nrov zoo.

5. Lub taub hau tseem ceeb txais lub zog sab nraud ntawm cov cua txias lubrication system, uas tsis tsuas yog txo qhov kub ntawm lub ntsiab ncej, tab sis kuj ua kom lub taub hau lub thawv huv si thiab lubricated.

6. Cov kev taw qhia kev tsheb nqaj hlau txuas nrog YT txoj siv tawv los txhim kho cov kev taw qhia kev ua kom zoo thiab qhov tseeb ntawm cov cuab yeej siv tshuab, thiab txhim kho kev pab cuam lub neej ntawm lub tshuab cuab yeej.

7. Lub ntsiab tsav iav yog tsim los ntawm Shenyang Machine Tool Group los xyuas kom meej tias lub suab nrov ntawm lub tshuab cuab yeej zoo.

Cov cuab yeej siv tshuab no yog siv dav hauv kev ua cov hydraulic kheej kheej, qhov ntev ncej thiab ntau yam.

Specification

| Yam khoom | Chav tsev | qw 1320 | qw 1323 |

| Max.tig txoj kab uas hla ntawm lub tshuab lub cev | mm | 630 | 630 |

| Max.workpiece ntev | mm | 1500 | 1500 |

| Max.tig txoj kab uas hla ntawm Tool tuav | mm | 350 | 350 |

| dav ntawm txaj | mm | 550 | 550 |

| Spindle bore | mm | 205 | 230 |

| Peb lub puab tsaig chuck | mm | 205 | 230 |

| Chuck specification |

| Φ500 phau ntawv peb lub puab tsaig chuck | Φ500 phau ntawv peb lub puab tsaig chuck |

| Spindle ceev | r / min | 18-450 Nws | 18-450 Nws |

| Main lub cev muaj zog | kw | 11 | 11 |

| Machining xov | Metric xov | 550 | 550 |

|

| 1-15 hli | 205 | 230 |

| 21 Hom | 1-15 hli | 205 | 230 |

| 21 Hom |

| Φ500 phau ntawv peb lub puab tsaig chuck | Φ500 phau ntawv peb lub puab tsaig chuck |

|

| Ntiv tes | 1-14 TSI | 18-450 Nws |

| 26 Hom | 1-14 TSI | 11 | 11 |

| 26 Hom | Metric xov |

|

|

| Maximum longitudinal mus txawv tebchaws ntawm lub eeb | mm | 1250 | 1250 |

| Spindle center rau Tool installation datum | mm | 32 | 32 |

| Tool seem loj | mm | 32 × 32 | 32 × 32 |

| Tailstock tes tsho diam | mm | 100 | 100 |

| Tailstock tes tsho mus ncig | mm | 250 | 250 |

| Taper ntawm tailstock taper qhov | Mohs | 5 | 5 |

| Lateral displacement ntawm tailstock | mm | ± 15 | ± 15 |

| Tshuab hnyav | Kg | 4 500 | 4 500 |

| Tshuab loj | mm | 3300x1450x1500 | 3300x1450x1500 |

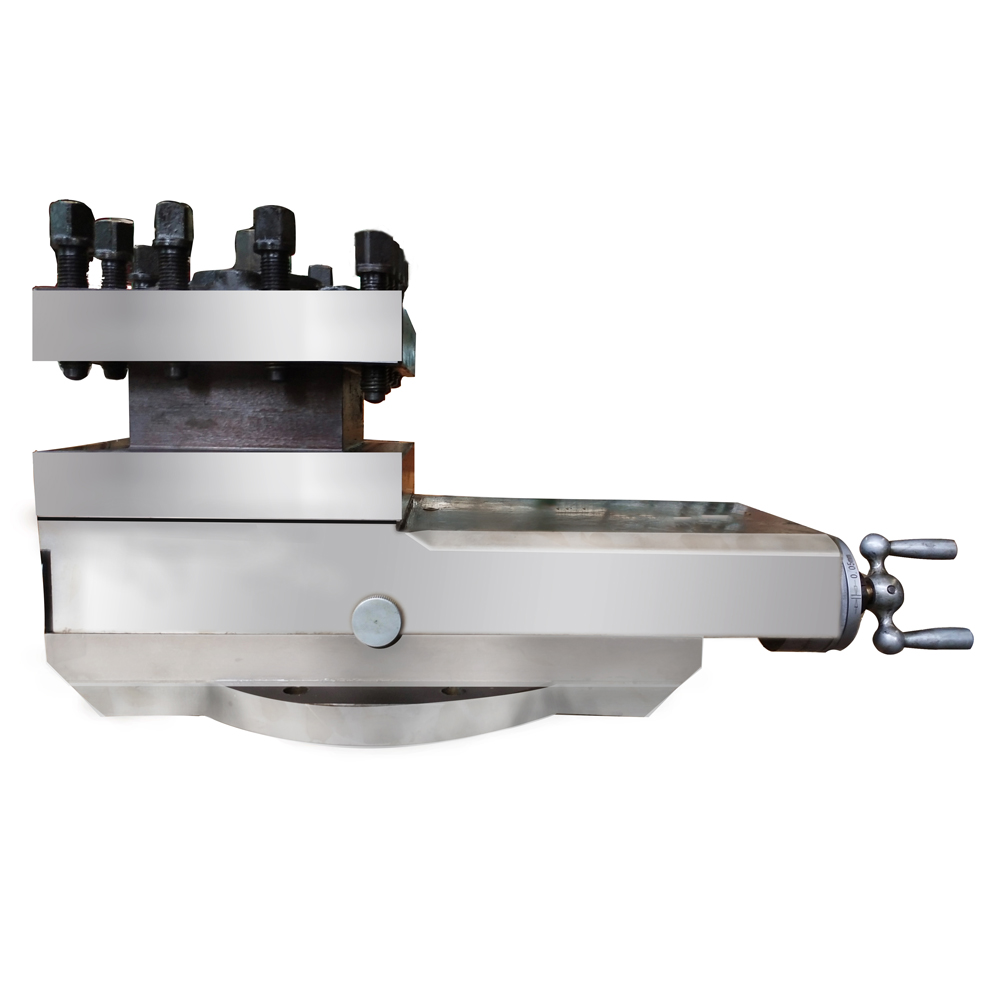

Cov duab ntxaws

Peb tsom ntsoov rau yuav tsum tau sib sau ua ke thiab txhim kho qhov zoo thiab kho cov khoom tam sim no, nyob rau hauv lub sijhawm tas li tsim cov khoom tshiab kom tau raws li cov neeg siv khoom tshwj xeeb 'yuav tsum tau muag zoo tshaj plaws Tuam Tshoj Precision CNC Yeeb Nkab Threading Tshuab dhos tshuab, Peb tsom rau kev tsim tus kheej hom thiab hauv ua ke nrog ntau yam kev paub dhau los thiab cov khoom siv thawj-chav kawm. Peb cov khoom koj tsim nyog muaj.

Peb tsom ntsoov rau yuav tsum tau sib sau ua ke thiab txhim kho qhov zoo thiab kho cov khoom tam sim no, nyob rau hauv lub sijhawm tas li tsim cov khoom tshiab kom tau raws li cov neeg siv khoom tshwj xeeb 'yuav tsum tau muag zoo tshaj plaws Tuam Tshoj Precision CNC Yeeb Nkab Threading Tshuab dhos tshuab, Peb tsom rau kev tsim tus kheej hom thiab hauv ua ke nrog ntau yam kev paub dhau los thiab cov khoom siv thawj-chav kawm. Peb cov khoom koj tsim nyog muaj.

Qhov zoo tshaj plaws-muag Tuam Tshoj CNC Roj Lub Tebchaws Tshuab dhos, CNC Roj yeeb nkab tshuab dhos, Peb txais tos koj tuaj xyuas peb lub tuam txhab thiab lub Hoobkas. Nws kuj yog ib qho yooj yim mus xyuas peb lub vev xaib. Peb pab neeg muag khoom yuav muab kev pabcuam zoo tshaj rau koj. Yog tias koj xav paub ntau ntxiv, thov hu rau peb ntawm E-mail lossis xov tooj. Peb vam thiab cia siab tias yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam mus sij hawm ntev nrog koj los ntawm lub sijhawm no, raws li kev sib luag, kev sib raug zoo los ntawm tam sim no mus rau yav tom ntej.