100% Thawj Hoobkas Tuam Tshoj CNC Khoom Ntoo Lathes. Khoom Ntoo Automatic Manual Lathes. Cylindrical Woodprocessing Ob-Spindle Tshuab dhos. Cnc woodworking tshuab dhos

Peb paub tias peb tsuas muaj kev vam meej yog tias peb tuaj yeem lav peb cov nqi sib tw ua ke thiab cov txiaj ntsig zoo tib lub sijhawm rau 100% Thawj Lub Hoobkas Tuam Tshoj CNC Khoom NtooTshuab dhoss. Khoom Ntoo Automatic Manual Lathes. Cylindrical Woodprocessing Ob-Spindle Tshuab dhos. Cncwoodworking Tshuab dhos, Rau cov neeg uas xav tau ib yam ntawm peb cov khoom los yog xav tham txog kev cai txiav txim, koj yuav tsum tuaj xav tias dawb hu rau peb. Peb tau saib ua ntej los tsim kom muaj kev sib raug zoo ntawm kev lag luam kev lag luam nrog cov neeg yuav khoom tshiab thoob plaws ntiaj teb nyob rau hauv ze rau lub peev xwm.

Peb paub tias peb tsuas yog vam meej yog tias peb tuaj yeem lav peb cov nqi sib tw ua ke thiab kev ua tau zoo zoo tib lub sijhawm rauTshuab dhos, Tag nrho cov khoom no yog tsim nyob rau hauv peb lub Hoobkas nyob hauv Suav teb. Yog li peb tuaj yeem lav peb qhov zoo thiab muaj txiaj ntsig. Hauv plaub lub xyoos no peb muag tsis yog peb cov khoom xwb tab sis kuj yog peb cov kev pabcuam rau cov neeg siv khoom thoob plaws ntiaj teb.

Daim Ntawv Qhia Txog Kev Ua Haujlwm

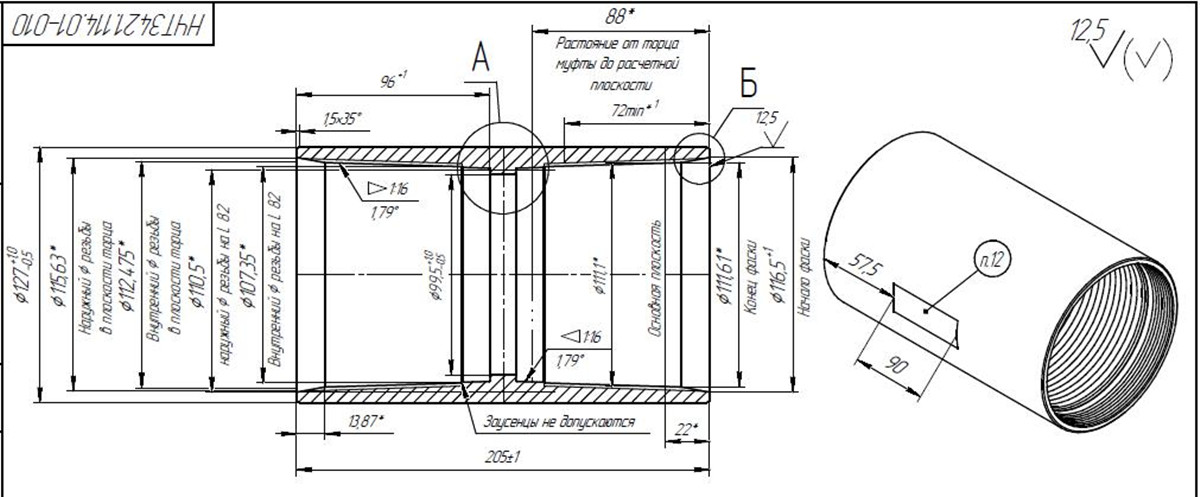

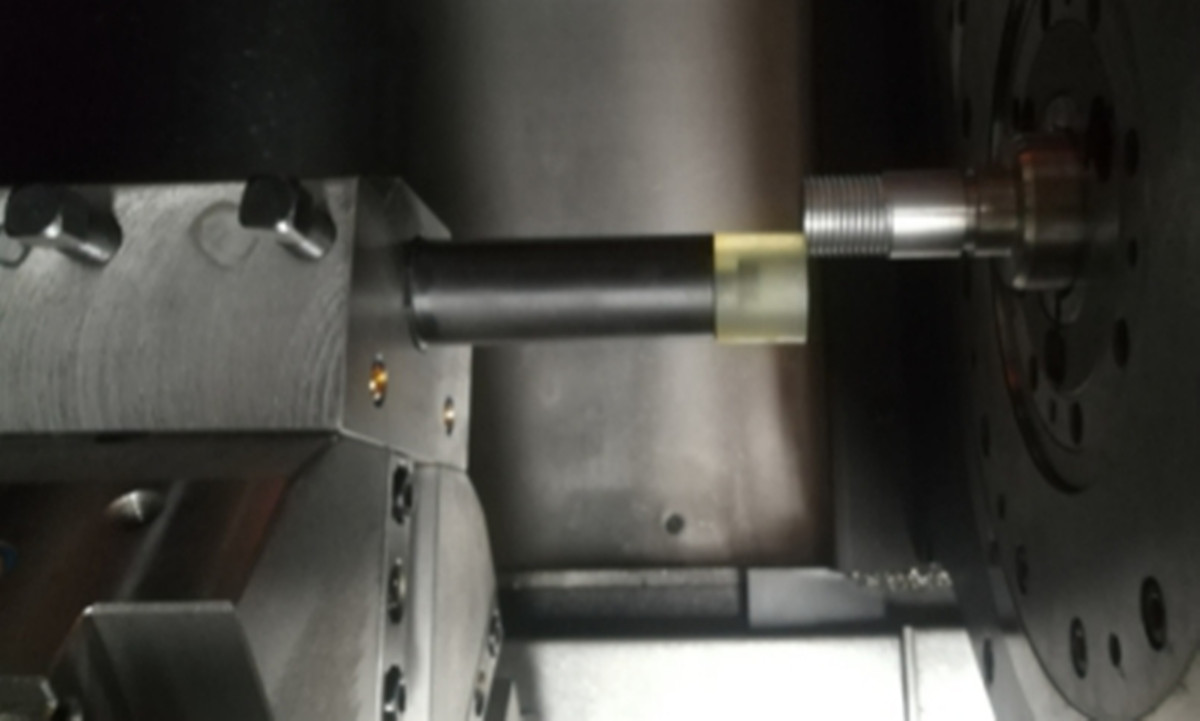

Raws li cov neeg siv khoom kos duab kos duab, Peb pom zoo rau SCK205S ob-kawg CNC tshuab dhos, uas clamps lub voj voog sab nraud ntawm kev sib txuas, thiab ua tiav ob qho tib si kawg thiab sab nraud chamfer, lub qhov thiab lub chamfer sab hauv, thiab cov xov sab hauv ( offset buckle) tib lub sijhawm.Ua API cov qauv.

| Tshooj No. | Max.sab nraud txoj kab uas hla (mm) | Ntev(mm) | Min. puab qhov (mm) | Ladder buckle (hauv) (API txuj) | Mark |

| Mуфта OТТМ 102-Д | ∮114 | 190 | ∮88.6 | 4 | |

| Mуфта IB 114-T | ∮127 | 205 | ∮99.5 | 4-1/2 | |

| 127 | ∮141.3 | 210 | ∮110 | 5 | |

| 140 | ∮153.7 | 218 | ∮130 | 5-1/2 | |

| 146 | ∮166 | 218 | ∮139.35 | 5-3/4 | |

| 168 | ∮187.7 | 225 | ∮151 | 6-5/8 | |

| 178 | ∮194.5 | 234 | ∮158 | 7 |

Tshuab Feature

1. Tshuab qauv thiab cov yam ntxwv

■ Lub tshuab no siv 450 inclined txaj layout, uas muaj zoo rigidity thiab yooj yim nti tshem tawm.

■ Lub headstock integrates peb yam ntawm lub ntsiab ncej, lub fixture, thiab lub tog raj kheej clamping. Cov qauv yog compact thiab txhim khu kev qha, thiab lub fixture yog hydraulically clamped.

Yuav kom ua tau raws li cov kev xav tau ntawm kev ua haujlwm

ntawm 4 "-7" couplings, kev daws teeb meem:

Qhov siab tshaj plaws clamping txoj kab uas hla: φ200mm,

Lub taub hau dav yog 190mm.

■ Lub clamp yog hom collet, thiab lub puab tsaig hloov kho yog ntsia rau ntawm elastic chuck nrog ib txoj kab uas hla ntawm 2 hli. Cov khoom ua haujlwm raug hloov. Thaum hloov txoj kab uas hla clamping, tsuas yog hloov lub puab tsaig tuaj yeem hloov tau.

■ Raws li cov khoom ua tiav, yuav tsum muaj ntau yam cuab yeej tho txawv. Txhawm rau kom tsis txhob cuam tshuam cov cuab yeej, lub turret yog customized. Lub rotary txoj kab uas hla ntawm lub taub hau cutter yog loj. Txhawm rau ua kom lub turret nruj dua, qhov nruab nrab ntawm lub turret raug xaiv los ua 125 hli.

Tswv yim: Xaiv ib tug ntxhib thiab zoo tho txawv cutter rau machining kawg lub ntsej muag, chamfer thiab puab lub qhov;

1 eccentric buckle xov cutter rau xov ua.

■ Lub tshuab cuab yeej yog nruab nrog ob-channel tswj qhov system. Ob lub cuab yeej tuav tau tuaj yeem txuas nrog lub ntxaiv tib lub sijhawm lossis cais ua kom tiav cov txheej txheem ib txhij lossis ua ntu zus ntawm ob qhov kawg ntawm ntu.

■ Axial positioning ntawm workpieces siv positioning posts mounted rau lub taub hau cutter.

■ Yuav kom ua tiav qhov deflection buckle ntawm ob qho kawg ntawm kev sib txuas tib lub sijhawm, txo cov lej ntawm kev hla tsawg.

Lub zog lub cev muaj zog nyob rau hauv cov ntaub ntawv no yog 18.5 / 22kW dav cheeb tsam servo lub cev muaj zog.

Specification

| Yam khoom | Lub npe | Chav tsev | Specification | Mark | |

| Txheej txheem Ntau yam | Max. viav vias saum txaj | mm | Φ550 | ||

| Max. viav vias hla tus swb | Φ350 | ||||

| Max.clamping txoj kab uas hla | Φ200 | ||||

| Ua ntev | Ncej 1000; Tube: 190-400 | ||||

| Spindle ceev | r / min | 1200 | |||

| Headstock | Headstock dav | mm | 190 | ||

| Spindle clamping specifications | Φ114-195 (4 nti-7 nti) | ||||

| Spindle bore | φ200 | ||||

| Spindle center rau hauv av qhov siab | 1150 | ||||

| Pub | Mus ncig | X1/X2 | 150/150 | ||

| Z1/Z2 | 480/600 ib | ||||

| Ua haujlwm tom ntej | X/Z | mm/r | 0.001-6 | ||

| Ceev ceev rau pem hauv ntej | X/Z | m/min | 16 | ||

| Tool | Tsav txoj kev | Rotary servo, xauv hydraulic |

| ||

| muaj peev xwm | chaw nres tsheb | Txoj kab uas hla ntawm tho txawv bar |

| ||

| Cov cuab yeej sab nraud square loj | mm | Txoj kab uas hla ntawm tho txawv bar | |||

| Txoj kab uas hla ntawm tho txawv bar | Φ50 | ||||

| Tshuab loj | mm | 4900 × 1850 × 1900 hli | |||

| Tshuab hnyav | Net nyhav | Kg | 6700 ib | ||

| Qhov hnyav tag nrho | 7700 ib | ||||

Main configurations

(●: txheem; ★: yeem)

| Tsis muaj. | Lub npe | Specification | Qty. | Hom | Keeb kwm | Mark |

| 1 | Tswj qhov system | FANUC 0i-TF | 1 Teeb | FANUC | Beijing | ★ |

| 2 | AC servo lub cev muaj zog | X axis/Z axis: 11 Nm | ||||

| 3 | Servo lub cev muaj zog | 18.5/22 kW, 307 Nm | ||||

| 4 | Spindle bearing | 1 Teeb | FAG | Lub teb chaws Yelemees | ● | |

| 5 | Servo tool tuav | Qauv: AK36125A-8 | 2sets | YTUM | Yantai | ● |

| 6 | Tool tais accessories | Cov cuab yeej tho txawv Φ50; Cov cuab yeej sab nraud □32 × 32 | 2sets | YTUM | Yantai | ★ |

| 7 | Elastic chuck | Nrog 2 specifications (raws li cov neeg siv khoom xav tau) | 1 Teeb | Tus kheej tsim | Yinchuang | ★ |

| 8 | Kho claw | Nrog 2 specifications (raws li cov neeg siv khoom xav tau) | 1 Teeb | Tus kheej tsim | Yinchuang | ★ |

| 9 | Pob ntsia hlau | X: 4008 Z: 4010 | 2sets | Hiwin | Taiwan | ● |

| 10 | Rolling qhia | 2sets | Hiwin | Taiwan | ● | |

| 11 | Ntsia hlau bearing | 2sets | NSK | Nyiv | ● | |

| 12 | Centralized lubrication | 1 Teeb | TTMN | Yongjia | ● | |

| 13 | Lub twj tso kua mis txias | 1 Teeb | Hauv tsev | Tuam Tshoj | ● | |

| 14 | Hydraulic system | 1 Teeb | YCCY | Yinchuang | ● | |

| 15 | Cov khoom siv hluav taws xob | ABB, Omron, thiab lwm yam. | 1 Teeb | Kev sib koom tes | Tuam Tshoj | ● |

| 16 | Tsis siv neeg nti tshem tawm | 1 Teeb | Yufeng | Yantai | ● | |

| 17 | Peb-xim teeb | 1 Teeb | Hauv tsev | Tuam Tshoj | ● | |

| 18 | Random ntaub ntawv | 1 Teeb | Tus kheej tsim | Yinchuang | ● | |

| 19 | Random txuas | 1 Teeb | Tus kheej tsim | Yinchuang | ● |

Peb paub tias peb tsuas muaj kev vam meej yog tias peb tuaj yeem lav peb cov nqi sib tw ua ke thiab cov txiaj ntsig zoo tib lub sijhawm rau 100% Thawj Lub Hoobkas Tuam Tshoj CNC Khoom Ntoo Lathes. Khoom Ntoo Automatic Manual Lathes. Cylindrical Woodprocessing Ob-Spindle Tshuab dhos. Cncwoodworking Tshuab dhos, Rau cov neeg uas xav tau ib yam ntawm peb cov khoom los yog xav tham txog kev cai txiav txim, koj yuav tsum tuaj xav tias dawb hu rau peb. Peb tau saib ua ntej los tsim kom muaj kev sib raug zoo ntawm kev lag luam kev lag luam nrog cov neeg yuav khoom tshiab thoob plaws ntiaj teb nyob rau hauv ze rau lub peev xwm.

100% Thawj Hoobkas Tuam Tshoj Cylindrical Woodprocessing Ob-Spindle Lathes, CNC Khoom Ntoo Lathes, Tag nrho cov khoom no yog tsim nyob rau hauv peb lub Hoobkas nyob hauv Suav teb. Yog li peb tuaj yeem lav peb qhov zoo thiab muaj txiaj ntsig. Hauv plaub lub xyoos no peb muag tsis yog peb cov khoom xwb tab sis kuj yog peb cov kev pabcuam rau cov neeg siv khoom thoob plaws ntiaj teb.