Dab tsi yog CNC drilling thiab milling tshuab:

CNC drilling tshuabbelongs rau hlau txiav tshuab cov cuab yeej, nrog rau lub luag hauj lwm ntawm lub qhov ua, drilling, tapping, tho txawv thiab pab milling. Nws yog tsuas yog siv rau high-efficiency drilling ntawm tiaj daim hlau, flanges, discs, rings, thiab lwm yam workpieces uas nws thickness yog nyob rau hauv lub zoo ntau yam.

Drilling los ntawm qhov thiab qhov muag tsis pom qhov yuav pom tau ntawm ib qho khoom siv thiab cov khoom sib xyaw. Cov txheej txheem machining ntawm lub tshuab cuab yeej yog digitally tswj, thiab kev ua haujlwm yooj yim heev. Nws tuaj yeem paub automation, siab precision, ntau yam, thiab ntau lawm.

CNC drilling thiab milling tshuabkhoom siv

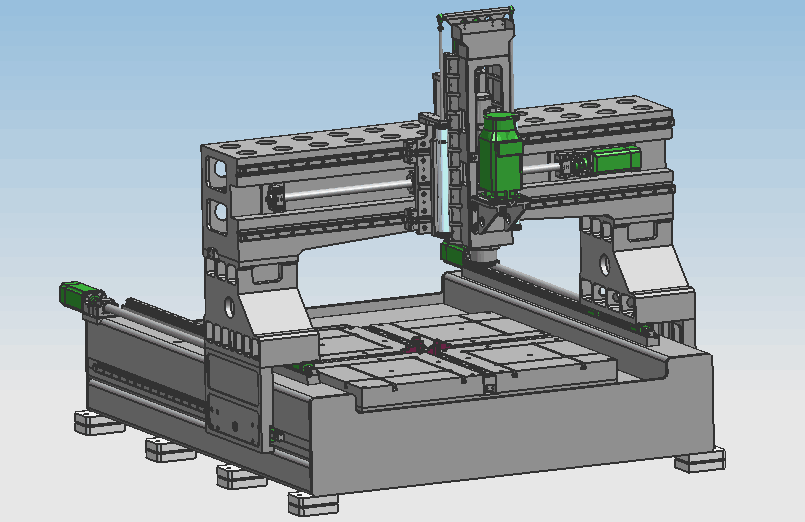

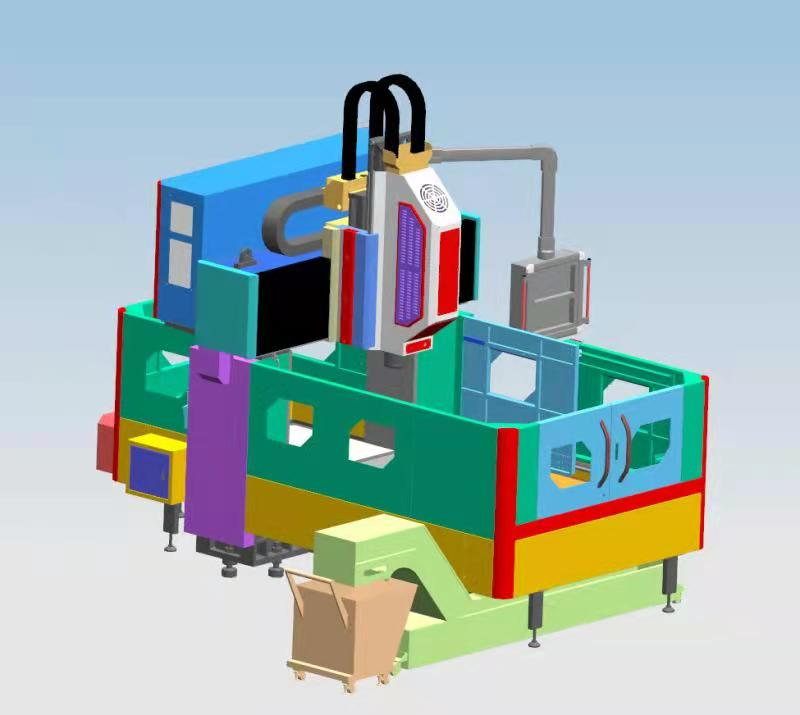

1. Lub txaj:

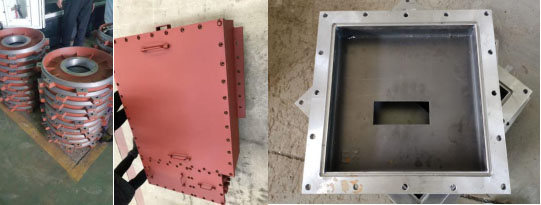

Lub txaj yog ib qho tseem ceeb ntawm cov txheej txheem, ua tiav los ntawm kev kho mob thib ob, nrog kev zoo dynamic thiab zoo li qub rigidity thiab tsis muaj deformation. Lub rooj ua haujlwm tau txais cov qauv casting, thiab muaj T-slot nrog qhov tsim nyog tiav ntawm lub dav hlau, uas yog siv los clamp lub workpiece. Lub kaw lus tsav siv AC servo lub cev muaj zog thiab precision pob ntsia hlau ob tog tsav ntawm ob sab kom lub gantry txav mus rau hauv X-axis kev taw qhia. Adjustable bolts yog faib rau hauv qab ntawm lub txaj, uas tuaj yeem kho tau yooj yim theem ntawm lub rooj ua haujlwm ntawm lub txaj.

2. Mobile hom gantry:

Lub gantry movable yog cam khwb cia thiab ua tiav los ntawm grey hlau (HT250), thiab ib khub ntawm dov linear qhia nrog ultra-siab muaj peev xwm yog ntsia rau pem hauv ntej ntawm lub gantry. Lub precision pob ntsia hlau khub thiab servo lub cev muaj zog ua rau lub taub hau hluav taws xob txav mus rau hauv Y-axis kev taw qhia, thiab lub tshuab hluav taws xob drilling tau nruab rau ntawm lub taub hau hluav taws xob. Qhov kev txav ntawm lub gantry yog pom tau los ntawm kev sib hloov ntawm lub pob ntsia hlau uas tau tsav los ntawm servo lub cev muaj zog los ntawm kev sib txuas ntawm qhov tseeb.

3. Tsiv zawv zawg eeb:

Qhov zawv zawg eeb yog qhov precision cam khwb cia hlau qauv. Cov zawv zawg zawv zawg yog nruab nrog ob lub ultra-siab load-bearing CNC qhia rail slides, ib txheej ntawm precision pob ntsia hlau khub thiab ib tug high-precision planetary reducer txuas nrog lub servo lub cev muaj zog tsav lub taub hau drilling zog txav mus rau Z-axis kev taw qhia tuaj yeem paub lub zog lub taub hau nrawm nrawm, ua haujlwm rau pem hauv ntej, nrawm rov qab, nres thiab lwm yam kev ua. Nws muaj cov haujlwm ntawm cov nti tsis siv neeg tawg, nti tshem tawm thiab nres.

4. Drilling hwj chim taub hau

Lub taub hau lub zog drilling siv lub zog servo spindle lub cev muaj zog, uas yog tsav los ntawm kev sib tsoo ntawm txoj siv sia kom txo tau lub zog kom tsav lub siab precision spindle. Lub spindle txais yuav pem hauv ntej plaub thiab lub rear ob rau kab ntawm Japanese angular hu bearings kom ua tau stepless hloov ceev. Lub ntxaiv yog nruab nrog lub tshuab pneumatic hloov pauv los ua lub cuab yeej Kev hloov pauv sai thiab yooj yim, thiab cov khoom noj yog tsav los ntawm servo lub cev muaj zog thiab lub pob ntsia hlau. X, Y, thiab Z axes tuaj yeem txuas thiab txais yuav ib lub voj voog kaw kom paub txog cov kab sib txuas thiab kev sib cuam tshuam.

LaumTshuab qhov zoo

1. Dej tawm ntawm qhov ntxaiv:

Nws txais yuav Taiwan lub Jianchun hom dej qhov hluav taws xob ntxaiv thiab lub zog loj servo spindle lub cev muaj zog los tsav cov ntxaiv los ntawm kev siv cov khoom siv synchronous deceleration kom torque. Nws tuaj yeem siv kev ua haujlwm siab U laum (kev xyaum ua nruj ua tsiv) thiab cov tub ntxhais laum me ntsis chaw ua dej.

2. Clamper

Lub X thiab Y axes tau nruab nrog cov khoom siv ua haujlwm siab siv ua ke nrog lub clamper thiab dov linear qhia khub. Siv lub hauv paus ntsiab lus ntawm cov kab nrib pleb, nws muaj lub luag haujlwm ntawm kev kho lub gantry, qhov chaw meej, tiv thaiv kev co thiab txhim kho rigidity. Cov qauv yog compact thiab muaj zog.

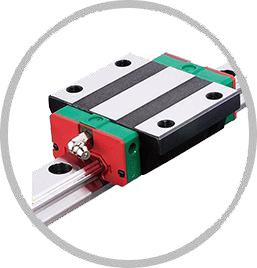

3. Cov ntawv qhia kab thiab pob ntsia hlau

Nws txais yuav Taiwan's Shangyin hom kab qhia kev tsheb nqaj hlau thiab TBI hom pob ntsia hlau. Cov kev taw qhia rails ntawm ob sab ntawm lub tshuab txaj yog ntsia vertically thiab parallel, thiab lub zog yog txawm, kom ruaj khov machining thiab khiav ntawm lub tshuab.

4. Lub zog lub taub hau sib npaug lub tog raj kheej

Muaj ob lub tog raj kheej sib npaug saum lub taub hau fais fab kom sib npaug qhov hnyav ntawm lub taub hau tshuab. Thaum lub sij hawm ua, lub taub hau tshuab yog ruaj khov, qhov smoothness ntawm lub qhov yog zoo dua, thiab hnav ntawm Z-axis ntsia hlau yog txo.

5. nti tshem tawm qhov system

Muaj cov saw phaj nti conveyor nyob tom qab ntawm lub tshuab cuab yeej. Siv nrog rab phom dej siab kom nrawm nrawm cov ntaub ntawv hlau rau hauv cov nti conveyor, uas xa cov ntaub ntawv hlau, txuag lub sij hawm rau kev ntxuav ntawm cov ntaub ntawv hlau thiab txo kev ua haujlwm. Lub nti conveyor yog nruab nrog lub tswb ntsuas hluav taws xob, uas tau txais lub tswb thaum cov kua txiav tsis txaus.

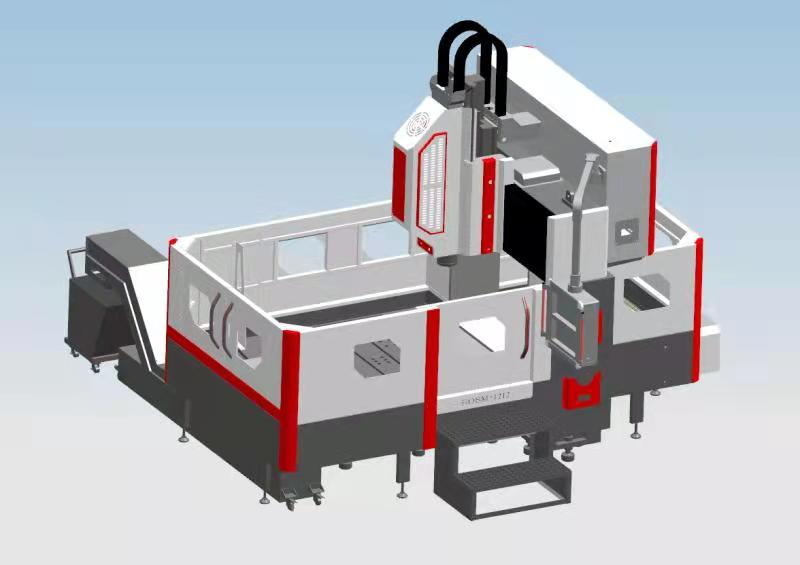

Qauv kev pom zoo

BOSM1600 * 1600 Nws tus kheej-centering CNC drilling thiab milling tshuab

BOSM1600 * 1600 hom kev kub ceevgantry CNC drilling thiab millingtshuabmuaj kev ua haujlwm zoo stroke ntawm 1600 * 1600, uas yog cov cuab yeej siv tau zoo. Lub tshuab muaj plaub lub puab tsaig-lub puab tsaig qhov chaw ua haujlwm, uas ua rau nws yooj yim dua thiab nrawm dua rau clamp lub nplhaib workpieces. Qhov siab tshaj plaws drilling yog 50, Nws tuaj yeem siv cov dej kub ceev hauv qhov hluav taws xob drilling, milling dav hlau, milling grooves, thiab lwm yam. Cov cuab yeej tuaj yeem nruab nrog lub cuab yeej magazine kom paub ntau yam txheej txheem hauv ib qho clamping.

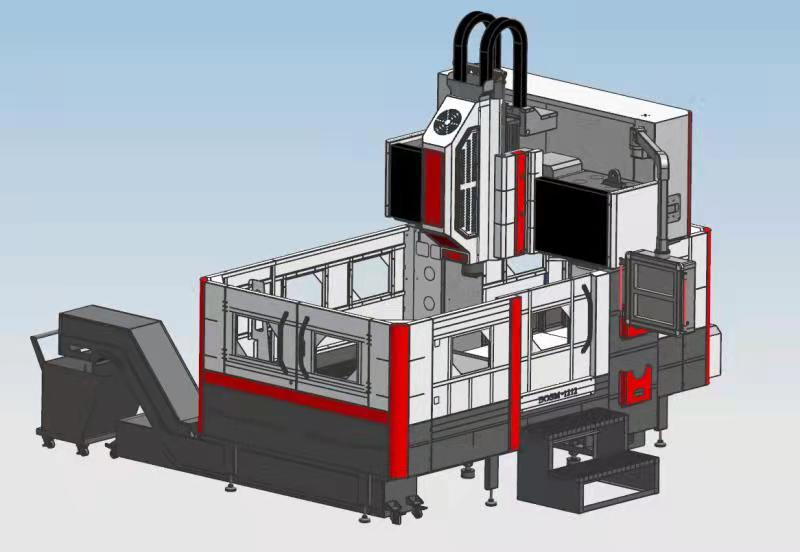

BOSM2500 * 2500 Nws tus kheej-centering CNC drilling thiab milling tshuab

BOSM-2525 Qhov sib cais-hom puv-cam khwb cia gantry homCNC siab ceevdrilling tshuab series yog tsuas yog siv rau high-efficiency drilling ntawm loj daim hlau, cua zog structural qhov chaw, discs, engineering machinery structural qhov chaw, li qub, raj ntawv thiab lwm yam workpieces nyob rau hauv lub zoo ntau yam. Milling. Drilling los ntawm qhov thiab qhov muag tsis pom qhov yuav pom tau ntawm ib qho khoom siv thiab cov khoom sib xyaw. Cov txheej txheem machining ntawm lub tshuab cuab yeej yog digitally tswj, thiab kev ua haujlwm yooj yim heev. Ntxiv rau cov qauv ua qauv, lawv kuj tuaj yeem tsim thiab kho raws li qhov xav tau tiag tiag ntawm cov neeg siv khoom.

CNC tsis siv neeg drilling tshuabyog tam sim no dav siv nyob rau hauv lub valve kev lag luam, flange kev lag luam, tawg-pov thawj hluav taws xob kev lag luam, cua zog kev lag luam, textile machinery kev lag luam, tsim machinery kev lag luam, machining kev lag luam, automotive kev lag luam, thiab lwm yam.

Rau cov neeg siv khoom uas tab tom ua cov khoom lag luam xws li flanges, rings, slewing kev txhawb nqa, cov ntawv raj, thiab lwm yam., cov kab sab nraud yog tsawg dua 2.2m, qhov ntsuas lub voj voog yog nyob rau hauv 2m inch, thiab lub aperture yog nyob rau hauv 50mm. Qhov mob taw tes rau cov neeg siv khoom ntawm cov khoom lag luam no nyob hauv lub sijhawm clamping Ntau tshaj li lub sijhawm ua haujlwm, cov cuab yeej ua haujlwm ib txwm siv, xws liCNC gantry milling tshuablos yog radial laum, siv lub clamp los clamp cov khoom tom qab kev thauj khoom, thiab tom qab ntawd siv lub ntug finder lossis siv cov cuab yeej tshaj lij los kuaj lub rooj kom pom qhov chaw, uas siv sijhawm thiab ua haujlwm zoo.

IB BOSMxyaumtshuabyog tsim los nrog lub rooj ua haujlwm ruaj khov thiab lub gantry txav. Nws txais yuav tus kheej-tsim loj-mus ncig plaub-lub puab tsaig self-centering chuck, uas daws cov teeb meem ntawm cov hydraulic me me los yog pneumatic puab tsaig ntawm lub khw. Cov workpieces loj yuav ntaus lub puab tsaig thaum hoisting Nyob rau hauv cov ntaub ntawv ntawm kev puas tsuaj rau lub chuck, lub workbench yog muab nrog ib tug sawb-zoo li tus qauv ncoo, thiab lub clamping yog cia li nyob rau hauv ib lub sij hawm, uas yuav daws tau qhov teeb meem ntawm lub sij hawm-siv clamping.

Plaub lub puab tsaig ntawm lub rooj zaum ua haujlwm tau txais ib qho kev tshem tawm. Tom qab disassembly, lub workbench tseem yog ib tug pa platform nrog T-slots, uas txhim kho nws daim ntawv thov ntau yam rau machining lwm yam workpieces sab nraum lub voj voog. BOSMCNC laum tshuabyog nruab nrog cov lus qhia rail clamp, 0.06 vib nas this siab heev qhib thiab kaw lub sij hawm, uas txhim kho lub machining raug thiab clamping quab yuam, thiab daws cov teeb meem yav dhau los ntawm spindle vibration thiab cuab yeej lub neej. Z-axis ob-balanced lub tog raj kheej, cab saw roj thiab roj sib cais los ntawm hluav taws xob, ruaj khov thiab nruj qauv, hluav taws xob txee beam yog qab rau kev thauj mus los yooj yim, qhov system boom style yog yooj yim rau kev khiav lag luam, thauj tog rau nkoj bolts siv tau tom qab tsaws thiab theem.

BOSMtsis siv neeg drilling tshuab tau txhim kho thiab txhim kho lub taub hau ib feem ntawm kab kab. Tom qab cov kab hloov pauv, cov ntawv hlau tsis muaj dej tsis zoo tau txhim kho, cov nyhuv dej tsis zoo yog qhov zoo tshaj plaws, thiab cov qauv tsim tuaj yeem ua kom zoo nkauj dua.

BOSM cnc drilling tshuab manufacturingyog nruab nrog lub hauv paus dej pom system, thiab cov dej siab yog qhov siab. Cov qauv ntawm lub tshuab txiav rov qab ntawm cov qauv no tsis yooj yim los ntxuav cov hlau txiav ntawm lub hauv ntej. Nws yog nruab nrog lub tsheb ntxhua khaub ncaws dej los ntxuav cov hlau txiav rov qab.

Valve kev lag luam

Flange kev lag luam

Kev lag luam tawg-pov thawj hluav taws xob

Cua fais fab kev lag luam

Textile machinery kev lag luam

Machining kev lag luam

Kev tsim kho tshuab kev lag luam

Automotive kev lag luam

Lub Hoobkas BOSM tseem niaj hnub koom ua lag luam thiab tsim cov qauv tshiab kom txo tau cov nqi tsim khoom thiab tsim khoom. Nws muaj ntau yam kev ua haujlwm, ua ke nrog kev paub txog kev ua haujlwm, thiab kev ua haujlwm zoo milling. Piv txwv li, BOSM-DPH1212 tsau beamgantry milling tshuabpeb tau tsim thiab tsim tam sim no. Rau cov neeg uas xav tau laum thiab zeb nrog qhov dav ntawm 1200mm lossis tsawg dua, kev lag luam gantrydrilling thiab milling tshuabuas tsis tuaj yeem ua tiav dhau qhov dav ntawm VMC850 machining chaw ntawm lub khw tuaj yeem paub cov neeg siv khoom milling-raws li kev ua haujlwm. Cov qauv ntawm cov txheej txheem.

Tus qauv BOSM-DPH1212 tuaj yeem paub qhov nrawm nrawm thiab kev thauj mus los, qhov dav tuaj yeem thauj mus rau hauv lub thawv, thiab nws tuaj yeem teeb tsa sai thiab siv ntawm tus neeg siv khoom qhov chaw. Txhais raws li ib tug tag nrho-round drilling thiabmilling tshuabcenter qauv, nws yog tsim nyog los xyuas kom meej qhov tseeb thiab rigidity ntawm lub tshuab cuab yeej. Daim ntawv qhia peb-axis yuav siv Taiwan hom kev qhia cov menyuam, sib tsoo cov ntsia hlau, thiab lub rooj ua haujlwm rau kev sib tsoo tshuab kom paub meej tias cov cuab yeej ua haujlwm tau zoo.

BOSM-DPH1212 tsau beam gantry milling sib zog ua lag luam uas qhov dav ntawm qhov chaw machining tsis tuaj yeem daws tau, thiab cov khoom lag luam yog khib nyiab nrog loj gantry milling. Piv txwv li, 1mCNC gantry machining chawnyob rau hauv kev ua lag luam, peb tab tom tsom rau ib tug loj tus naj npawb ntawmCNC drilling tshuab, milling, thiab tho txawv. Kev lag luam thov rau machining, kuj tseem muaj kev lag luam uas daws qhov teeb meem ntawm kev ntxhib machining ntawm pwm-hom engraving thiab milling electromechanical spindles.

Post lub sij hawm: Sep-20-2021