CovOturnCenter-Drive tshuab dhosyog ib qho kev ua tau zoo, siab-precision, thiab cov cuab yeej tsim khoom siab heev, nrog ntau yam kev siv tshuab hauv tsev. Cov khoom tuaj yeem raug clamped ib zaug kom ua tiav lub voj voog sab nrauv, lub ntsej muag kawg, thiab lub qhov ntawm ob qhov kawg ntawm lub workpiece tib lub sijhawm, thiab cov khoom tuaj yeem clamped ob zaug piv nrog cov txheej txheem ib txwm ua ntawm U-tig, qhov nruab nrab -tsav tshuab dhos muaj ntau dua efficiency thiab siab dua coaxial precision ntawm cov txheej txheem. Tam sim no, peb lub tuam txhab tau tsim ntau tshaj kaum qhov tshwj xeeb ntawm cov khoom siv ob lub taub hau thiab tau qhia rau kev ua lag luam. Clamping Txoj kab uas hla yog li ntawm φ5mm-φ250mm, thiab kev ua haujlwm ntev li ntawm 140mm-2500mm.

Lwm hom khoom yog aOb chav spindle CNC tshuab dhos, uas yog tsim rau tig disc los yog luv ncej qhov chaw nrog ib txoj kab uas hla ntawm Φ200mm thiab lub siab tshaj plaws puab qhov ntev ntawm 120mm. Cov khoom yog cia li docked los ntawm dual spindles kom tiav tag nrho cov txheej txheem ntawm ob theem. Qhov saum toj no ob hom CNC tshuab dhos tuaj yeem nruab nrog tsis siv neeg thauj khoom thiab tshem tawm thiab khaws cia kom paub txog kev tsim khoom tsis siv neeg.

Qhov nruab nrab tsavCNC tshuab dhosyog ib tug tsis yog-tus qauv customized CNC tshuab dhos, uas belongs rau tshwj xeeb tshuab cuab yeej. Cov neeg siv khoom siv cov khoom siv, koom tes nrog cov txheej txheem kev thov, tswj hwm tus nqi zoo, ua kom cov neeg siv khoom txaus siab thov ua haujlwm zoo. Piv nrog rau ib-txoj kev machining ntawm cov tsoos CNC tshuab dhos, nruab nrab-tsav tshuab dhos siv lub headstock los ua bidirectional machining ntawm workpiece, thiab theoretical machining efficiency yog ob zaug ntawm cov tsoos tshuab dhos. Tshwj xeeb tshaj yog rau disk-type workpieces lossis ncej-hom batch-processing workpieces uas yuav tsum tau coaxiality siab thiab tsis yooj yim rau clamped ob zaug,mid-tsav CNC tshuab dhosyog yuav luag tsuas muaj txiaj ntsig thiab tuaj yeem lav qhov coaxiality thiab qhov tseeb. tshuab.

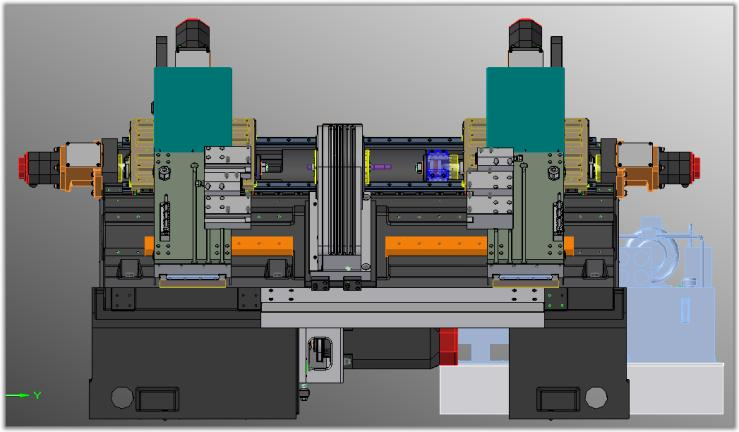

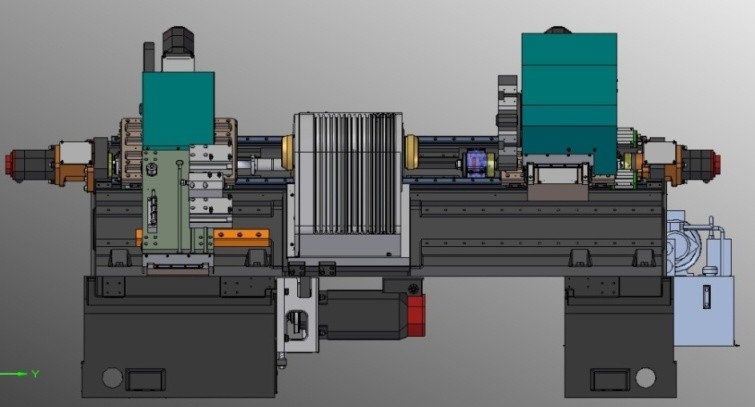

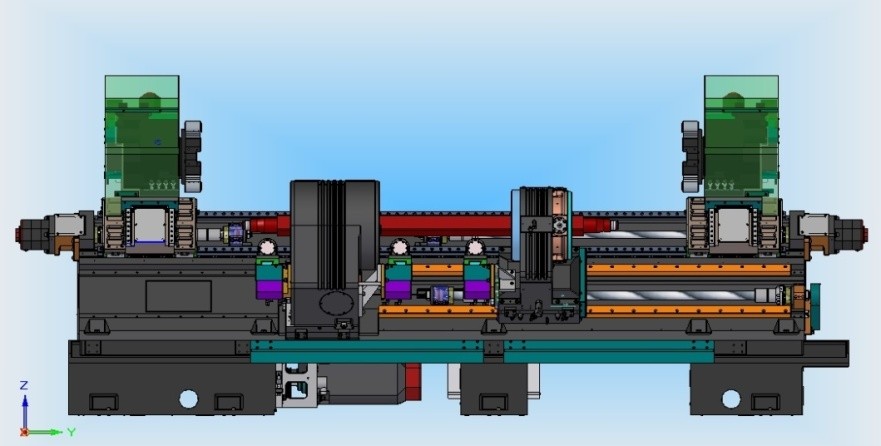

Cov ob lub taub hau CNC tshuab dhos Feem ntau muaj cov khoom nram qab no: sab laug thiab sab xis zawv zawg rooj, sab laug thiab sab xis loj thauj khoom, sab laug thiab sab xis longitudinal pob screws, sab laug thiab sab xis longitudinal servo motors, cov khoom siv hluav taws xob thiab cov lej tswj. Nruab nrab ntawm sab laug thiab sab xis zawv zawg rooj, muaj lub rooj zaum spindle fixedly txuas rau nws. Lub rooj zaum spindle yog nruab nrog lub hollow spindle, lub thawv kis tau tus mob thiab zaus hloov lub cev muaj zog. Hollow lub ntsiab ncej, lub thawv kis tau tus mob thiab zaus hloov lub cev muaj zog. Cov tsheb loj sab laug thiab sab xis yog nruab nrog kab rov tav sab laug thiab sab xis nruab nrab. Sab laug thiab sab xis nruab nrab cov tsheb thauj khoom yog nruab nrog sib npaug rau sab laug thiab txoj cai kab rov tav pob ntsia hlau thiab sab laug thiab txoj cai kab rov tav servo motors.

Ib leeg / ob lub taub hau

Cov cuab yeej ncej: teb / kab cuab yeej / lub zog

Hydraulic fixture: hom collet, hom claw

Multi-configuration / multi-function rau xaiv

Qhov zoo ntawm Center-tsav tshuab dhos

1. Concentration ntawm cov txheej txheem, txo tus naj npawb ntawm workpiece clamping lub sij hawm.

2. Thaum clamping, ob qhov kawg yuav ua tiav tib lub sijhawm.

3. Txo cov txheej txheem ntau lawm.

4. Nruab nrog kev thauj khoom thiab tshem tawm cov khoom siv thiab cov khoom siv khaws cia kom paub txog cov khoom siv hluav taws xob tag nrho.

5. Lub workpiece yog clamped nyob rau hauv nruab nrab txoj hauj lwm, lub clamping yog txhim khu kev qha, thiab lub torque yuav tsum tau xa mus rau lub tshuab txiav yog txaus, thiab ib tug loj margin yuav tig.

Tshuab taw qhia:

Raws li Tuam Tshoj qhov zoo tshaj plawsCenter Drive Tshuab dhos tshuab Hoobkas, peb txais 45 ° inclined txaj layout, uas muaj zoo rigidity thiab yooj yim nti khiav tawm. Lub taub hau nrog nruab nrab tsav clamping muaj nuj nqi yog teem rau hauv nruab nrab ntawm lub txaj, thiab ob lub cuab yeej tuav tau teem rau ntawm ob sab ntawm lub taub hau. Cov ntawv qhia dov tau txais yuav, thiab txhua lub servo pub ncej txais lub siab-mute pob ntsia hlau, thiab cov hlua txuas txuas ncaj qha, thiab lub suab nrov qis, qhov chaw raug thiab qhov rov ua dua qhov tseeb yog siab..

Nruab nrog lub kaw lus dual-channel tswj, ob lub cuab yeej so tuaj yeem txuas rau lub ntxaiv tib lub sijhawm lossis cais ua kom tiav ib txhij lossis ua ntu zus ntawm ob qhov kawg ntawm ntu. Cov cuab yeej siv tshuab txais cov qauv tsim qauv thiab tuaj yeem muaj ntau yam qauv, teeb tsa, thiab kev ua haujlwm ua ke raws li koj xav tau. Muaj ob txoj kev xaiv rau tus tuav riam, kab riam hom lossis hom turret. Cov kab tuav rab riam muaj peb txheej ntawm cov lus qhia ntev ntev, thiab plaub rab riam tuaj yeem ntsia tau nce thiab nqis.

Ib leeg spindle, sab laug turret gang cuab tam, txoj cai turret qauv

Ib leeg spindle, sab laug thiab txoj cai tuav cov cuab yeej yog cov cuab yeej ua laib

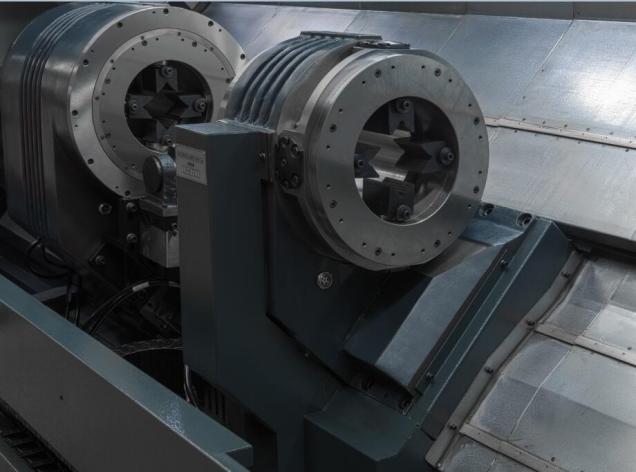

Raws li qhov tsis muaj qhov xwm txheej, qhov loj me, thiab cov duab ntawm ib feem, txoj kev clamping, axial ntev, los ntawm lub qhov taub thiab clamping txoj kab uas hla ntawm lub thawv spindle nruab nrog txhua lub tshuab tshwj xeeb tuaj yeem xaiv nyias. Nruab nrab clamping thiab ob kawg yog clamping. Lub collet-type headstock, nruab nrab clamping, thiab ob-kawg clamping lub puab tsaig-hom headstock, muaj extension headstock, ultra-short headstock, siab clamping raug headstock, thiab qhov tseeb clamping tuaj yeem ncav cuag 0.005mm. Qhov ntev ntawm ib feem tuaj yeem nruab nrog ib lub taub hau ib leeg lossis ob lub taub hau taub hau.Lub taub hau ntawm lub tshuab dhos nruab nrab tsav yog tsau, thiab lub taub hau sub-headstock tuaj yeem txav tau axially (manually movable lossis servo-movable). Nws kuj tseem siv tau rau ob lub thawv spindle yog clamped los ua kom tiav cov txheej txheem ntev, thiab nws kuj tseem siv tau los tsuas yog siv lub thawv spindle los clamp kom tiav cov txheej txheem luv luv. Lub thawv spindle integrates peb yam ntawm cov spindle system fixture, clamping, thiab roj kheej kheej. Cov qauv yog compact thiab kev ua haujlwm yog txhim khu kev qha.

Qhov siab tshaj plaws machining ntev ntawm ob lub taub hau yog 2500mm, thiab qhov siab tshaj plaws los ntawm qhov taub ntawm lub taub hau tuaj yeem ncav cuag Φ370mm. Cov khoom siv clamping yog tag nrho cov hydraulically tsav, thiab lub zog clamping tuaj yeem ua tau raws li qhov xav tau ntawm qhov siab tshaj plaws tig torque. Muaj ntau txoj kev xaiv rau lub chuck yog hais tias lub cheeb ntawm ib feem yog teev muaj ntau, txais yuav cov qauv ntawm kev txhim kho lub claw nyob rau hauv lub chuck, uas yog heev yooj yim thiab ceev los hloov.

CovCenter Drive CNC tshuab dhoskuj tseem tuaj yeem nruab nrog cov khoom siv tsis siv neeg thauj khoom thiab tshem tawm thiab cov khoom siv cia kom paub txog kev ua haujlwm tsis siv neeg.

Lub tshuab dhos nruab nrab tsav yog tag nrho nyob rau hauv thiab tiv thaiv, nruab nrog tsis siv neeg lubrication thiab tsis siv neeg nti tshem tawm cov cuab yeej, nrog kev tiv thaiv zoo, kev ua haujlwm yooj yim thiab kev saib xyuas yooj yim.

Qhov chaw tsim nyog rau nruab nrab-tsav tshuab dhos ua:

1. Auto qhov chaw:

Gearbox input ncej, gearbox tso zis ncej, welded qag, kauj pas nrig, ib nrab ncej, ncej raj, shock absorber piston raj, trailer qag, torsion bar.

Gearbox input ncej

Gearbox tso zis ncej

kauj kauj

Ib nrab ncej

Shock absorber

Lub cev

2. Lwm yam khoom siv kho tshuab:

Lub cev muaj zog ncej, spinning tshuab cov menyuam, lub raj mis pwm, roj laum yeeb nkab sib koom, lub twj tso kua mis rotor ncej, tshuab luam ntawv nruas.

spinning tshuab cov menyuam thiab lub cev muaj zog ncej

roj laum yeeb nkab sib txuas thiab lub twj tso kua mis rotor ncej

Iav pwm Thiab Printing tshuab nruas

Lub ntsiab kev lag luam uas nruab nrab tsav lathes siv:

1. Kev lag luam tsheb:

Machining ntawm iav shafts ntawm tsheb gearboxes

Ua lub tsheb trailer axles

Processing tsheb hub qag raj

Processing tsheb qag raj

Machining tsheb caj npab ncej

Processing tsheb qag ncej

2. Textile machinery kev lag luam:

Ua spinning tshuab rau cov menyuam

3. Pwm kev lag luam:

Ua iav lub raj mis pwm

4. Lub cev muaj zog kev lag luam:

Machining lub cev muaj zog ncej

5. Dej twj kev lag luam:

Ua dej twj tso kua mis rotor ncej

6. Printing machinery kev lag luam:

Tshuab luam ntawv xovxwm cylinders thiab daim hlau

Ib qho point ntawm covntxaib ntxaivCNC tshuab dhostseem ceeb heev. Lub workpiece fixture yog siv los kho lub workpiece ntawm spindle thaum lub sij hawm machining txheej txheem. Lub zog tsim tawm thaum lub sijhawm machining txheej txheem thiab cov khoom ruaj khov yuav tsum ruaj khov thiab tsis muaj qhov khoob. Cov fixtures nrog ruaj khov zoo yog ze ze rau cov kev tsim muaj zog thiab R & D muaj peev xwm. Kev koom tes zoo tshaj plaws ntawm peb cov kws tsim kho tshuab, hluav taws xob engineers thiab software engineers tuaj yeem suav tias yog kev txhawb nqa kev ua tiav.

Peb pab pawg engineers yuav raug kho raws li qhov tshwj xeeb xav tau ntawm cov neeg siv khoom hauv kev lag luam sib txawv. Ntxiv nrog rau kev ua haujlwm siab ntawm ob qho kawg ib txhij ua tiav ntawm nruab nrab-tsav tshuab dhos, nws kuj zoo heev txo cov neeg siv khoom tus nqi nkag.

CovCNC ob lub taub hau tshuab dhosyog cov cuab yeej siv tshuab tshwj xeeb, thiab nws yog ib qho qauv tsim tsis siv neeg hauv kev tsim cov kab ntau lawm. Lub CNC ntxaib ntxaiv tshuabyog kev koom ua ke. Kev txhim kho, tsim thiab xaiv cov cuab yeej siv tshuab, cov khoom siv thiab cov cuab yeej, kev tshuaj xyuas thiab ntsuas, kev thauj mus los, kev tiv thaiv thiab kev kho cov chips thiab coolant yog tag nrho hauv ib qho. Cov cuab yeej siv tshuab tshwj xeeb yog tsim los ntawm ib lub tshuab. Raws li cov neeg siv khoom xav tau, ib qho tsim, ib qho kev tsim kho, thiab ib qho kev tsim khoom yuav tsum tau ua kom muaj kev vam meej ib zaug.

Covob chav spindle tshuab dhoskev ua haujlwm tivthaiv kev lag luam tau tsim kev lag luam kev lag luam hauv Suav teb, thiab sib piv rau cov neeg txawv teb chaws nyob rau hauv cov nqe lus ntawm kev tsim khoom thiab cov chaw kho vajtse. Ua ke nrog qhov tshwm sim ntawm ntau lub lag luam tshiab nyob rau xyoo tas los no, cov tuam txhab no tau tsim cov cuab yeej ua tiav thiab cov tswv yim thev naus laus zis hauv tsev thiab txawv teb chaws, thiab ib txwm txuas ntxiv mus tshawb fawb thiab tsim kho, nrog rau kev txhim kho txuas ntxiv thiab kev ua tiav hauv kev tsim kho tshiab. cov qauv, nrhiav kev ua tau zoo thiab Kev Zoo, ntau cov lus pom zoo hauv kev lag luam thoob ntiaj teb, tau lees paub thiab lees txais los ntawm ntau thiab ntau tus neeg siv khoom txawv teb chaws.

Post lub sij hawm: Sep-18-2021