Covkab rov tav machining centeryog tsim rau kev ua haujlwm nrog cov duab tsis yooj yim, ntau cov txheej txheem ua tiav, cov kev xav tau siab, ntau hom kev siv tshuab zoo tib yam thiab ntau cov txheej txheem cov cuab yeej, thiab ntau yam clamping thiab kho kom tiav cov txheej txheem.

Cov khoom tseem ceeb yog raws li nram no:

Qhov chaw nrog ob qho tib si tiaj tus thiab qhov

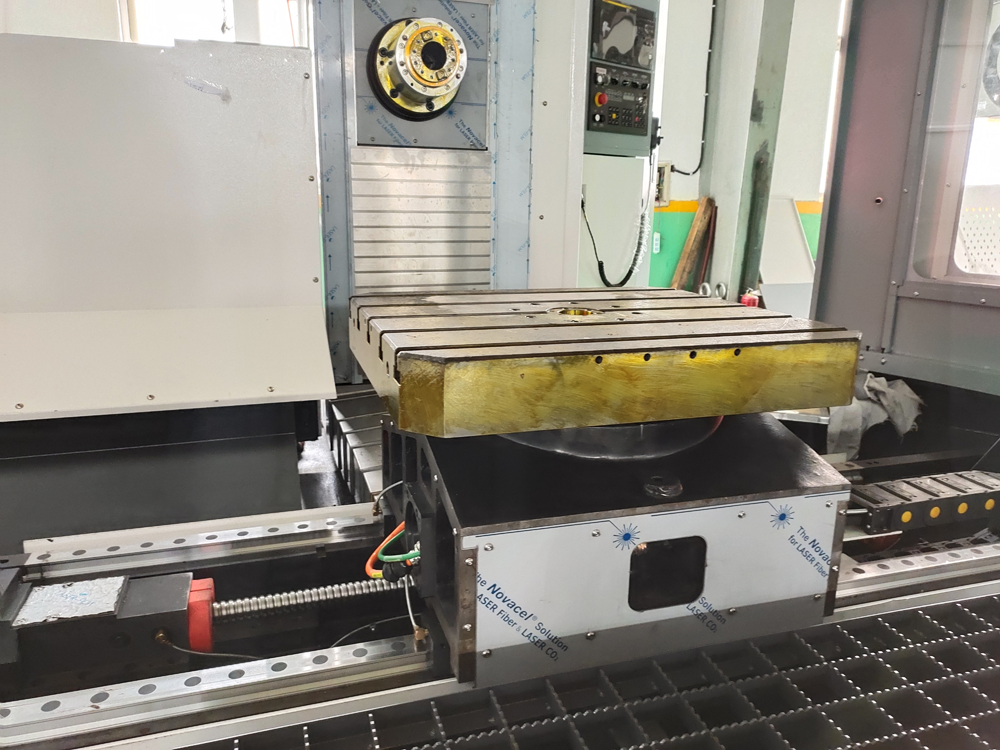

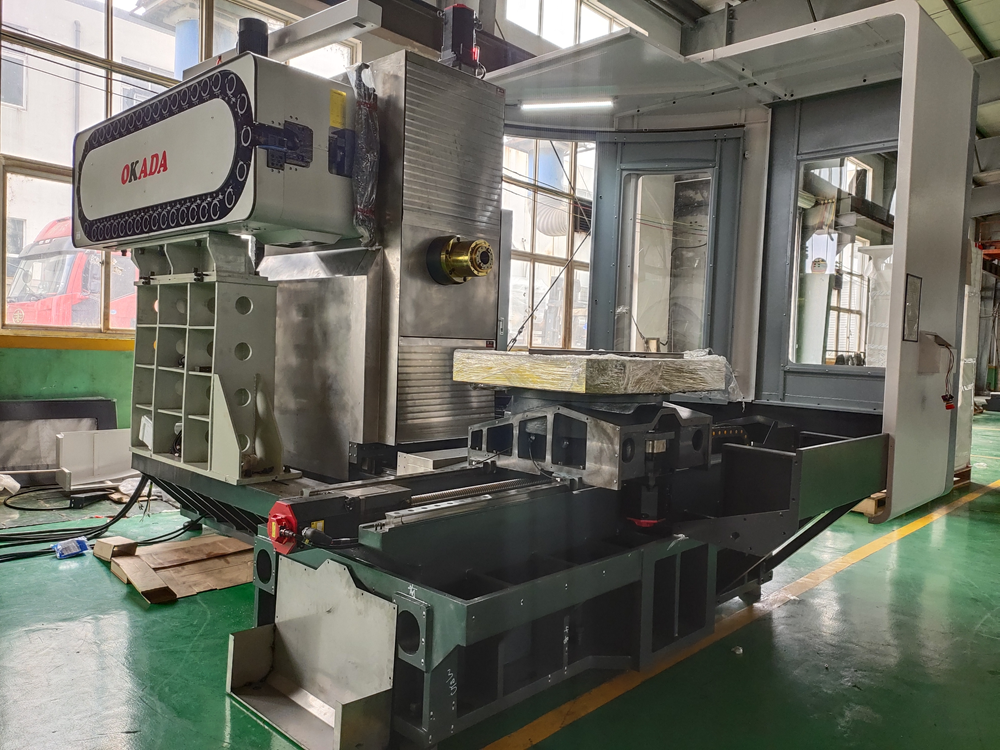

Ob lub rooj kab rov tavmachining chawmuaj lub tshuab hloov pauv tsis siv neeg. Hauv ib qho kev teeb tsa, nws tuaj yeem ua kom tiav qhov milling ntawm qhov chaw, qhov drilling, tho txawv, reaming,milling thiab tappingntawm qhov system. Cov txheej txheem ua tiav tuaj yeem yog nyob rau hauv ib lub dav hlau lossis ntawm cov dav hlau sib txawv. Yog li ntawd, cov khoom siv nrog ob lub dav hlau thiab lub qhov system yog cov khoom ua haujlwm ntawm qhov chaw machining, thiab cov khoom siv feem ntau yog lub thawv-hom qhov chaw thiab phaj, lub tes tsho, thiab phaj-hom qhov chaw.

1. Lub thawv qhov chaw. Muaj ntau lub thawv-hom qhov chaw. Feem ntau, ntau qhov chaw nres tsheb qhov system thiab kev ua dav hlau yuav tsum tau ua. Cov kev xav tau raug yog siab, tshwj xeeb tshaj yog cov duab raug thiab qhov tseeb ntawm txoj haujlwm yog nruj. Feem ntau, milling, drilling, expansion, tho txawv, reaming, countersinking, thiab tapping yog yuav tsum tau. Tos rau cov kauj ruam ua haujlwm, muaj ntau yam cuab yeej uas yuav tsum tau ua, nws yog ib qho nyuaj rau kev ua haujlwm ntawm cov cuab yeej siv tshuab zoo tib yam, cov cuab yeej siv ntau ntau, thiab qhov tseeb tsis yooj yim los lav. Qhov kawg kev teeb tsa ntawm lub chaw machining tuaj yeem ua tiav 60% -95% ntawm cov txheej txheem cov ntsiab lus ntawm cov cuab yeej siv tshuab zoo tib yam. Qhov tseeb ntawm cov khoom yog qhov zoo, qhov zoo yog ruaj khov, thiab lub voj voog ntau lawm yog luv.

2. Discs, lub tes tsho thiab phaj phaj. Muaj cov dav hlau, qhov chaw nkhaus thiab qhov ntawm qhov kawg ntawm lub ntsej muag ntawm cov khoom xws li, thiab qee qhov feem ntau faib rau hauv cov kev taw qhia radial. Vertical machining center yuav tsum raug xaiv rau disc, lub tes tsho, thiab phaj qhov chaw uas nws cov khoom siv tau yog nyob rau ntawm ib qho kawg, thiab kab rov tav machining chaw yuav tsum raug xaiv rau qhov chaw uas nws cov khoom tsis yog nyob rau saum npoo ntawm tib txoj kev.

3. Cov khoom tshwj xeeb-puab xa mus rau cov khoom uas muaj cov duab tsis zoo xws li brackets thiab hloov rab diav rawg. Feem ntau ntawm lawv yog kev sib xyaw ua ke ntawm cov ntsiab lus, kab thiab qhov chaw. Vim yog cov duab tsis zoo, cov cuab yeej siv tshuab zoo tib yam tuaj yeem siv lub hauv paus ntsiab lus ntawm cov txheej txheem dispersion rau kev ua, uas yuav tsum tau siv ntau dua thiab lub voj voog ntev dua. Siv cov yam ntxwv ntawm ntau qhov chaw nres tsheb, kab thiab qhov chaw sib xyaw ua haujlwm ntawm qhov chaw machining, feem ntau lossis txawm tias tag nrho cov txheej txheem tuaj yeem ua tiav.

Post lub sij hawm: Dec-13-2021