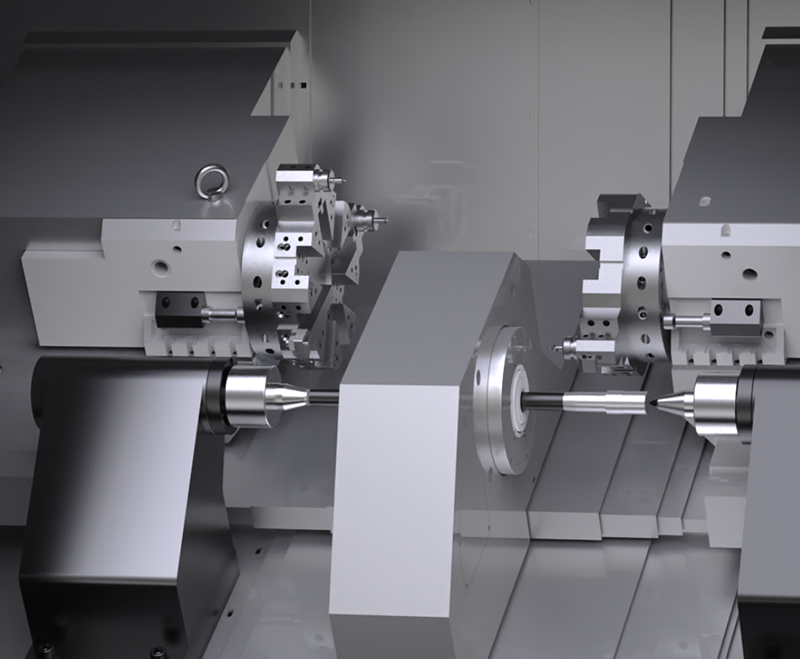

Dual-spindle CNC tshuab dhosyog cov cuab yeej tseem ceeb hauv kev tsim khoom niaj hnub, nrog rau lawv cov kev ua haujlwm ruaj khov thiab kev ua tiav ncaj qha cuam tshuam rau kev tsim khoom thiab cov khoom zoo. Yog li ntawd, kev tu txhua hnub ntawm cov tshuab no yog qhov tseem ceeb tshwj xeeb. Los ntawm kev saib xyuas tsim nyog, tsis tsuas yog lub neej ntev ntawm cov cuab yeej siv tau ntev, tab sis nws txoj kev ua tiav thiab kev ua haujlwm ruaj khov kuj tuaj yeem ua kom ntseeg tau, yog li txhim kho kev tsim khoom thiab txo cov nqi kho.

Qhov tseem ceeb ntawm Kev Kho Txhua Hnub

1.Extending khoom Lifespan

Dual-spindle CNC lathes muaj kev sib txawv ntawm kev hnav thiab cuam tshuam rau lawv cov khoom thaum siv. Kev tu tsis tu ncua, lubrication, thiab kev tshuaj xyuas tuaj yeem pab txheeb xyuas thiab daws cov teeb meem uas muaj peev xwm, xws li cov lus qhia hnav thiab cov hlua khi xoob, tiv thaiv cov teeb meem me los ntawm kev ua txhaum loj thiab ua kom ntev lub neej ntawm cov khoom siv.

2.Ua kom cov cuab yeej Precision

Kev ua precision ntawmOb chav spindle CNC tshuab dhosyog ib qho tseem ceeb qhia txog lawv kev ua tau zoo. Qhov tseeb ntawm cov khoom tseem ceeb xws li cov lus qhia thiab cov ntsia hlau lead ncaj qha cuam tshuam rau qhov tseeb qhov tseeb thiab qhov zoo ntawm qhov chaw ua haujlwm. Los ntawm kev saib xyuas txhua hnub, xws li tu cov khib nyiab tsis tu ncua los ntawm cov lus qhia thiab lubricating cov ntsia hlau, cov khoom no tuaj yeem tswj xyuas lawv qhov tseeb, ua kom cov khoom ua tiav raws li cov qauv tsim.

3. Txhim kho kev ua haujlwm ruaj khov thiab kev ntseeg tau

Thaum lub sij hawm ua haujlwm, dual-spindle CNC lathes xav tau kev sib koom tes ua haujlwm ntawm ntau lub subsystems, suav nrog hluav taws xob, cua txias, thiab lubrication systems. Ib qho tsis ua haujlwm hauv cov kab ke no tuaj yeem ua rau cov khoom siv poob qis, cuam tshuam rau cov sijhawm tsim khoom. Kev saib xyuas tsis tu ncua, xws li tshuaj xyuas cov kev sib txuas ntawm cable, ntxuav lub tshuab ua kom txias, thiab hloov cov roj nplua nyeem, xyuas kom meej tias tag nrho cov subsystems ua haujlwm zoo, txhim kho tag nrho kev ruaj ntseg thiab kev ntseeg siab ntawm cov khoom siv.

4.Kev txo tus nqi txhaum cai thiab cov nqi kho mob

Kev saib xyuas tsis tu ncua tuaj yeem txheeb xyuas thiab daws cov teeb meem tam sim ntawd, tiv thaiv kev tsim khoom los ntawm cov khoom siv tsis ua haujlwm. Tsis tas li ntawd, lub sijhawm kho kom zoo tuaj yeem txuas ntxiv lub voj voog loj ntawm cov khoom siv, txo cov nqi tu.

Txoj Kev Kho Mob Tshwj Xeeb

1.Kev tu thiab lubrication tsis tu ncua

Phau Ntawv Qhia Kev Tu: Ua kom huv cov lus qhia tsis tu ncua kom tswj tau lawv cov smoothness thiab precision.

Lead Screw Lubrication: Tsis tu ncua lubricate txhuas screws kom txo kev sib txhuam thiab tswj lawv cov precision thiab lifespan.

Lubrication System Inspection: Tsis tu ncua xyuas lub lubrication system cov roj theem thiab zoo kom paub tseeb tias nws ua hauj lwm ib txwm.

2.Electrical System Inspection

Cable Connection Check: Tsis tu ncua xyuas cov kev sib txuas cable kom paub tseeb tias lawv muaj kev nyab xeeb.

Hluav taws xob Cheebtsam: Tsis tu ncua xyuas cov khoom hluav taws xob, xws li relays thiab contactors, kom ntseeg tau tias lawv ua haujlwm zoo.

3.Txhim kho cua txias

Coolant Check: Tsis tu ncua xyuas lub coolant qhov kub thiab txias kom paub tseeb tias lub cua txias system ua hauj lwm ib txwm.

Cooling System Cleaning: Tsis tu ncua ntxuav lub tshuab cua txias kom tshem tawm cov khib nyiab thiab tswj kom huv.

4.Tool Magazine thiab Tool Changer Maintenance

Tool Magazine Cleaning: Nquag ntxuav cov cuab yeej magazine kom ntseeg tau tias cov cuab yeej khaws cia zoo thiab tsis txhob sib tsoo.

Tool Changer Inspection: Tsis tu ncua tshuaj xyuas lub cuab yeej hloov pauv kom ntseeg tau tias nws ua haujlwm li qub.

5. Tshuab dhos Precision Maintenance

Theem Position Check: Tsis tu ncua xyuas lub tshuab dhos txoj hauj lwm kom paub tseeb tias nws precision.

Mechanical Precision Calibration: Tsis tu ncua calibrate mechanical precision kom tswj tau lub tshuab dhos ua precision.

Tsim Kho Kev Npaj Kho Mob

Txhawm rau kom muaj kev ua haujlwm li qub thiab kev ua neej nyob ntawmdual-spindle CNC tshuab, tuam txhab uas muag yuav tsum tsim ib tug scientific zoo tu lub hom phiaj. Txoj kev npaj no yuav tsum muaj xws li:

Maintenance Cycle: Tsim kom muaj lub sijhawm tu ncua raws li kev siv cov cuab yeej siv thiab cov lus pom zoo ntawm cov chaw tsim khoom.

Cov Ntsiab Lus Kho: Kom meej meej cov ntsiab lus ntawm txhua qhov kev saib xyuas, xws li ntxuav, lubrication, thiab tshuaj xyuas.

Kev cob qhia cov neeg ua haujlwm tu: Muab kev cob qhia tsim nyog rau cov neeg ua haujlwm saib xyuas kom ntseeg tau tias lawv tuaj yeem ua haujlwm tau raug.

Cov Ntaub Ntawv Kho Mob: Khaws cov ntaub ntawv tu xyuas kom ntxaws txhawm rau taug qab cov khoom siv thiab keeb kwm.

Los ntawm kev ua raws li kev tswj hwm txoj kev npaj, cov tuam txhab tuaj yeem txhim kho kev ua tau zoo thiab kev ruaj ntseg ntawm dual-spindle CNC lathes, muab kev txhawb zog rau kev tsim khoom thiab kev loj hlob.

Hauv cov ntsiab lus, kev saib xyuas txhua hnub ntawm dual-spindleCNC tshuab dhosNws yog ib qho tseem ceeb rau kev ua kom muaj kev ua haujlwm ib txwm muaj, ua kom lub neej ntev, txhim kho kev ua tiav, thiab txhim kho kev ruaj ntseg. Cov tuam txhab lag luam yuav tsum ua qhov tseem ceeb ntawm kev saib xyuas kev ua haujlwm, txhim kho txoj kev npaj kho kom zoo, thiab ua tiav nws nruj me ntsis txhawm rau txhim kho kev tsim khoom thiab cov khoom zoo.

Post lub sij hawm: Apr-02-2025