Raws li peb txhua tus paub, nyob rau hauv niaj hnub machinery manufacturing kev lag luam, cov lag luam muaj ntau yam kev thov raucov cuab yeej siv tshuab tshwj xeeb. Feem ntau, cov tshuab drilling zoo tib yam muaj kev siv zog ua haujlwm siab, tsis tshua muaj kev ua haujlwm tshwj xeeb, qis tsim khoom thiab tsis muaj kev lees paub ntawm qhov tseeb; thaum tshwj xeeb ntau lub qhovcov tshuab drillingyog qhov yooj yim, txuag zog, yooj yim rau tus tswv, thiab tsis nquag ua haujlwm tsis raug thiab tsis ua haujlwm. Lawv tuaj yeem tsis tsuas yog txo cov neeg ua haujlwm qaug zog, thiab ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm thiab cov tshuab drilling. Nws muaj kev nyab xeeb thiab tuaj yeem txhim kho kev tsim khoom ntawm lub tshuab drilling. Nrog kev txhim kho txuas ntxiv ntawm kev tshawb fawb thiab thev naus laus zis,tshwj xeeb drilling tshuabyog dav siv nyob rau hauv manufacturing. Hauv lwm lo lus, qhov muaj zog tshwj xeeb, qhov zoo dua lub tuam txhab tuaj yeem lav qhov zoo ntawm nws cov khoom. Yog li ntawd, kev siv cov cuab yeej siv tshuab tshwj xeeb ua lub luag haujlwm tseem ceeb hauv kev sib tw ntawm kev lag luam.

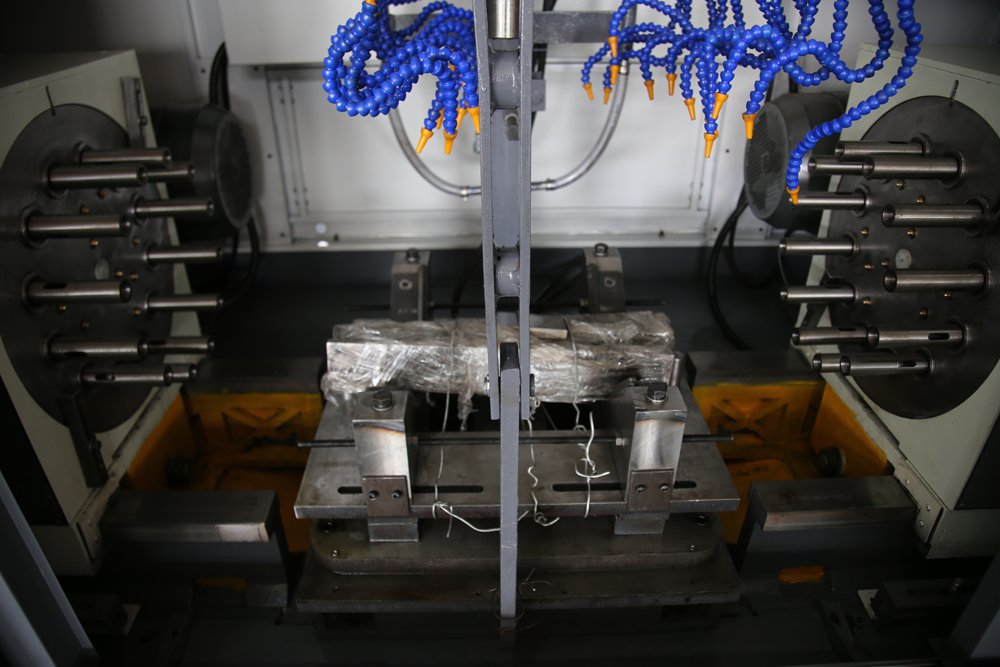

Covmulti-qhov drilling tshuabua los ntawm peb lub Hoobkas tshwj xeeb yog tsom rau ntawmvalve kev lag luam. Nws tuaj yeem paub txhua yamrooj vag li qub, npauj npaim li qub, tswj li qubthiab lwm yam li qub. Peb-lossis ob sab flanges ua los ntawm cam khwb cia hlau lossis cam khwb cia hlau tuaj yeem ua taudrilled thiab tappedtib lub sijhawm. Ntxiv nrog rau qhov ua tau zoo ntawm kev ua haujlwm ntawm lub valve, lwm qhov chaw thov tseem ceeb, xws li kev ua cov twj tso kua mis lub cev, nws pib qhov chaw, engineering machinery thiab lwm qhov chaw, kuj tuaj yeem siv rau tib lub sijhawm drilling ntawm qhov kawg, qhov nruab nrab, qhov tapered thiab spherical qhov ntawm lub workpiece. Qhov kev ua haujlwm. Qhov ntau-qhov laummuaj ob hom hydraulic thiab cov lej tswj kev ua haujlwm, uas tuaj yeem paub txog automation, siab precision, ntau yam, thiab ntau lawm.

Kuj tseem muaj qee qhov kev ceev faj thaum sivmulti-qhov xyaum. Peb tau sau cov ntsiab lus hauv qab no rau qhov no:

1) Lub laum me ntsis yuav tsum tau kho tus kheej thiab ntim, thiab nws yuav tsum ruaj khov thaum lub sijhawm thauj mus los kom tsis txhob muaj kev vibration thiab kev sib tsoo.

2) Txhawm rau ntsuas txoj kab uas hla ntawm lub laum me ntsis, siv lub ntsuas tsis sib cuag xws li lub tshuab tsom iav kom tsis txhob raug mob los ntawm kev sib cuag nrog cov neeg kho tshuab.

3) Covntau spindle drillinglub taub hau fais fab yuav tsum tau siv lub tshuab drilling template positioning nplhaib thaum siv, yog li ntawd lub elongation ntawm lub laum me ntsis ntsia rau ntawm spindle yuav tsum tau kho kom zoo ib yam. Multi-spindlecov tshuab drillingyuav tsum tau them sai sai rau qhov no, yog li ntawd qhov tob tob ntawm txhua qhov ntxaiv yuav tsum yog Unanimous.

4) Txheeb xyuas qhov hnav ntawm qhov txiav ntug ntawm lub laum.

5) Covmulti-qhov drilling tshuabyuav tsum xyuas qhov concentricity ntawm spindle thiab chuck tsis tu ncua. Tsis zoo concentricity yuav ua rau me me-inch drills tawg thiab ua kom lub qhov taub. Tsis zoo clamping quab yuam yuav ua rau qhov tseeb ceev yuav tsis sib haum nrog lub teeb ceev. Yuav muaj kev swb ntawm cov khoom laum.

6) Lub clamping ntev ntawm ntau lub qhov laum me ntsis ntawm lub chuck yog 4 mus rau 5 npaug ntawm txoj kab uas hla ntawm lub laum shank kom clamped ruaj khov.

7) Nco ntsoov xyuas lub spindle. Lub ntsiab ncej tsis tuaj yeem raug shaken los tiv thaiv kev xyaum tawg thiab ib nrab qhov thaum lub sij hawm drilling.

8) Cov txheej txheem tso rau ntawm qhov chaw ua haujlwm ntawm ntau lub qhov laum yog khov kho thiab nteg tiaj tus, uas ua rau lub neej ntev ntawm lub laum me ntsis thiab txo cov nqi tsim khoom thiab cov nqi. Cov nyhuv sib tsoo ntau dhau yog qhov tsis zoo.

Post lub sij hawm: Nov-20-2021