i5M8.4 Tsib-axis txuas High-end version 20220623

| Yam khoom | Chav tsev Nqe (USD) | Qty. | Tus nqi (USD) | Lus hais |

| I5M8.4 Tsib-Axis Machining Center (Five-axis linkage high-end version) | $132,812.00 Nws | 1set ib | $132,812.00 Nws | i5 CNC system, BT40 12000 rpm |

| Tus nqi FOB tag nrho | $132,812.00 Nws | |||

| Lub sij hawm xa tuaj | Hauv Tshuag. | |||

| Kev them nyiaj | 30% T / T ua ntej, 70% T / T yuav them ua ntej xa khoom. | |||

| Pobhauv & shipping | Lub tshuab yuav tau ntim nrog Standard export ntim. | |||

| Kev siv tau | Hauv 30 hnub. | |||

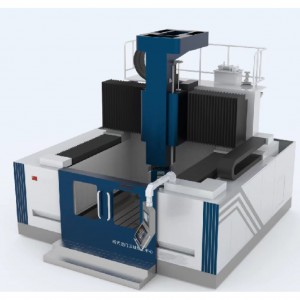

Tsib-Axis Vertical Machining Center

Lub i5M8.4 ntse multi-axis ntsug machining chaw yog ib tug high-ceev tsib-axis machining chaw, uas yog siv rau saj zawg zog thiab npaum machining ntawm valve lub cev, nyias-walled, plhaub, thiab ncej qhov chaw.Lub tshuab no tau nruab nrog ob-axis turntable raws li tus qauv, thiab cov khoom ua haujlwm tuaj yeem ua tiav thiab ua tiav ntau yam txheej txheem xws li kev kub ceev milling, tho txawv, drilling, reaming, thiab tapping rau ntau lub dav hlau tom qab ib qho clamping.

Tag nrho lub tshuab txais lub gantry txav beam qauv, txais yuav high-speed direct-tsav hluav taws xob spindle, thiab linear axis txais kev sib txuas ntawm lub cev muaj zog, uas muaj cov yam ntxwv ntawm kev kub ceev, siab acceleration thiab siab rigidity.Lub tsib-axis turntable txais kev ncaj qha-tsav torque lub cev muaj zog, uas muaj txoj haujlwm siab thiab kev ua haujlwm zoo.Nws tsis tsuas yog muaj kev ua tau zoo ntawm kev kub ceev txiav hauv chav tsev lub sijhawm, tab sis kuj ua rau cov khoom ua tiav kom tau txais qhov siab precision thiab siab roughness.Kev ua haujlwm yog teem rau 5-axis txuas, uas yog, tsuas yog X, Y, Z, A, thiab C axes txuas rau kev txiav thaum lub sijhawm ua haujlwm.

i5 system nta

i5 txhais tau tias (Kev Lag Luam, Cov Ntaub Ntawv, Internet, Kev Sib Koom Tes, Kev Txawj Ntse),

i5 txhais tau tias (Kev Lag Luam, Cov Ntaub Ntawv, Internet, Kev Sib Koom Tes, Kev Txawj Ntse),

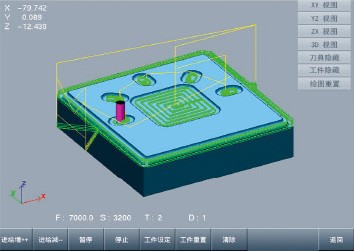

Kev sib koom ua ke zoo ntawm industrialization, kev qhia, kev sib tham, kev sib koom ua ke thiab kev txawj ntse.Lub kaw lus yuam kev them nyiaj thev naus laus zis yog thawj coj, thiab kev tswj xyuas qhov tseeb mus txog qib nanometer.Cov cuab yeej siv tshuab siv lub tshuab i5 tuaj yeem ua tiav 3μm los ntawm kev them nyiaj ua kom zoo yam tsis tas yuav tsum muaj cov lus pom zoo.

Raws li kev tswj hwm kev tswj hwm qib siab hauv qab thev naus laus zis thiab thev naus laus zis thev naus laus zis, i5 system muab yug rau Internet-based ntse davhlau ya nyob twg, uas paub txog kev ua haujlwm ntse, kev ua haujlwm ntse, kev saib xyuas ntse thiab kev tswj xyuas ntse:

Kev ua haujlwm ntse: ua kom yooj yim rau cov neeg siv kev lag luam los ntawm kev taw qhia cov duab, tsis siv neeg hom sib txuam, puv npo kev sib cuam tshuam thiab lwm yam thev naus laus zis, tso cai rau cov neeg siv "mus ncaj qha nrog ib tus yuam sij";lub interface customization muaj nuj nqi kev koom ua ke nyob rau hauv lub CNC system tuaj yeem kho qhov sib txawv interfaces raws li cov neeg siv xav tau, thiab hloov pauv sai.

Kev txawj ntse programming: Lub programming ntawm lub voj voog tuaj yeem ua tiav los ntawm kev siv lub graphical interface;lub kaw lus muaj kev ua haujlwm ntawm 3D simulation thiab txhawb kev saib ua ntej ntawm txoj kev ua haujlwm thaum ua haujlwm.Nyob rau tib lub sijhawm, lub kaw lus tseem tuaj yeem pom zoo txiav cov kev txwv rau cov neeg siv los ntawm txoj kev xaiv, txo cov nra ntawm cov neeg ua haujlwm.cov txheej txheem xav tau.

Kev saib xyuas kev txawj ntse: Los ntawm kev ua haujlwm ntawm cov duab kos duab thiab kuaj cov chaw taws teeb, nws tuaj yeem pab cov neeg siv kom pom sai thiab tshem tawm qhov tsis raug, txo cov kev xav tau ntawm cov neeg ua haujlwm tu, thiab txo cov neeg siv sijhawm;thiab lub kaw lus tuaj yeem hloov kho tau yooj yim thiab nrawm thiab hloov kho kom lub tshuab cuab yeej mus txog hnub nrog cov thev naus laus zis tshiab synchronize.

Kev tswj hwm ntse: Nws tuaj yeem muab cov cuab yeej siv hauv Is Taws Nem cov lus nug muaj nuj nqi, thiab siv huab tswj hom los saib xyuas, tswj thiab txheeb xyuas cov cuab yeej siv tshuab ua haujlwm, kev txiav txim tiav thiab lwm yam ntaub ntawv los ntawm browser.

Paub txog qhov sib kis tsis zoo, qhov chaw raug, tsis tshua muaj zog thiab zoo li qub kev sib txhuam, siab rhiab heev, tsis tshua muaj kev vibration ntawm kev kub ceev, tsis muaj kev nkag ntawm qhov qis ceev, siab qhov chaw raug, thiab ceev traverse ceev mus txog 30/30/30m / min

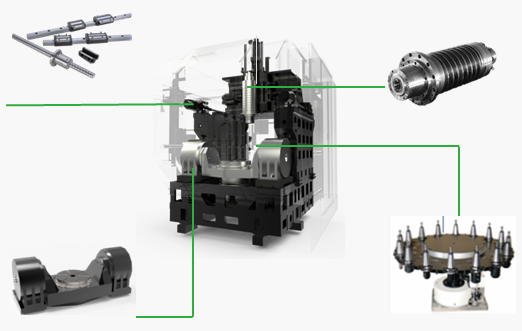

Kev hloov pauv tau yooj yim thiab muaj zog siab ceev milling motorized spindle txais kev siv tshuab ncaj qha, nrog qhov siab tshaj plaws ntawm 12000r / min, lub zog siab tshaj plaws ntawm 15kw, lub zog siab tshaj plaws ntawm 96Nm, thiab BT40 cov cuab yeej interface.

High-torque thiab high-precision cradle-type turntable, qhov siab tshaj plaws A / C ceev yog 50r / min, A-axis rotation range yog ± 120 °, C-axis rotation ntau yog nX360 °, A / C axis positioning Qhov tseeb yog 10 ″, thiab qhov rov ua qhov tseeb yog 6 ″.

Lub thoob kaus mom-hom cuab yeej magazine los ntawm Taiwan Zhenshang yog saws, uas tuaj yeem thauj khoom 20 cov cuab yeej.Lub cev muaj zog tsav lub indexing, uas tuaj yeem khiav ntawm kev kub ceev thiab tsis muaj suab nrov.Lub spindle tuav lub cuab yeej, thiab lub cuab yeej hloov txheej txheem yog ceev thiab raug.

Tshuab tej yam kev mob

Lub tshuab yuav tsum tsim nyog rau kev siv nyob rau hauv ib puag ncig tiag tiag thiab kev ua haujlwm tau teev tseg hauv qab no:

Ø Fais fab mov: 380V ± 10% 50HZ ± 1% peb-theem AC

Ø Siv qhov kub thiab txias: 5 ℃ ~ 40 ℃

Ø Qhov kub zoo tshaj plaws: 15 ℃ ~ 25 ℃

Ø txheeb ze humidity: 40 ~ 75%

Ø Huab cua qhov siab: 0.5 ~ 0.7MPa

Ø Cua khiav: 350L / min

Main parameter

| Yam khoom | ib 5m8.4 | Chav tsev | ||||

| Lub rooj ua haujlwm | Worktable loj | φ400 | mm | |||

| tso cai siab tshaj load | 300 | kg | ||||

| T-qhov loj me | 14 × 8 | Mmxpics | ||||

| Kev ua ntau yam | Skateboard Max Travel - X Axis | 600 | mm | |||

| Kev mus ncig siab tshaj plaws ntawm nqaj - Y axis | 500 | mm | ||||

| Spindle Max Travel - Z Axis | 450 | mm | ||||

| Kev ncua deb ntawm spindle kawg lub ntsej muag mus rau lub rooj ua haujlwm | siab kawg | 530 | mm | |||

| yam tsawg kawg nkaus | 80 | mm | ||||

| A-axis taug kev | ± 120 | ° | ||||

| C-axis taug kev | xwm 360 | ° | ||||

| Spindle | Lub khob hliav qab | BT40 | ||||

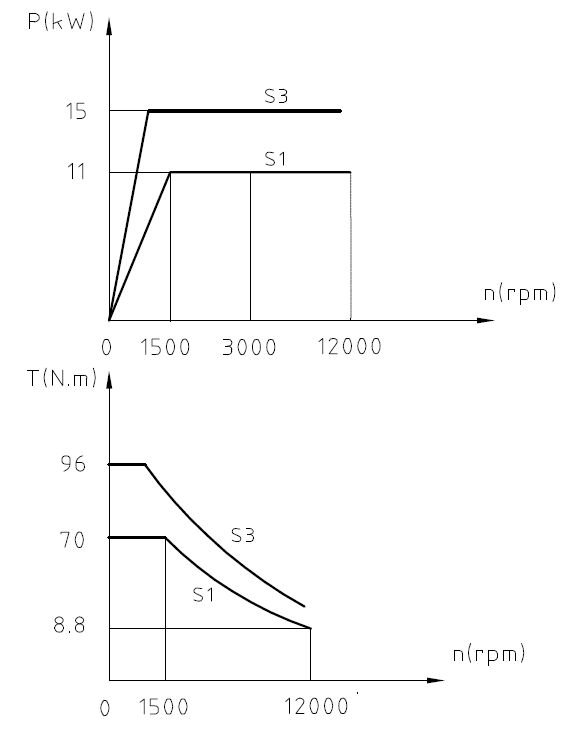

| Ntau zaus ntawm kev hloov pauv | 12000 | r / min | ||||

| Tawm tawm torque (100% / 40%) | 70/96 ib | Nm | ||||

| Spindle lub cev muaj zog (100% / 40%) | 11/15 | KW | ||||

| Spindle kis hom | Hluav taws xob spindle | |||||

| Tool | Shank qauv | BT40 | ||||

| Pub | txav ceev ceev | X axis | 30 | m/min | ||

| Y axis | 30 | |||||

| Z axis | 30 | |||||

| Peb-axis tsav lub cev muaj zog (X / Y / Z) | 3.6/3.6/5.8 | KW | ||||

| Pub tus nqi | 20 | m/min | ||||

| Tool magazine | Tool magazine daim ntawv | kaus mom style | ||||

| Txoj kev xaiv cuab yeej | Spindle tshem tawm | |||||

| Cov cuab yeej magazine muaj peev xwm | 20 | Daim | ||||

| Cov cuab yeej siv ntev tshaj plaws | 250 | mm | ||||

| Qhov siab tshaj plaws qhov hnyav | 7 | kg | ||||

| Qhov siab tshaj plaws cutter taub hau txoj kab uas hla | tag nrho cov cuab yeej | φ115 | mm | |||

| Cov cuab yeej uas nyob ib sab | φ130 | mm | ||||

| Lub sijhawm hloov cuab yeej (①) | 6-8 | s | ||||

| Positioning raug | X axis | 0.008 ib | mm | |||

| Y axis | 0.008 ib | mm | ||||

| Z axis | 0.008 ib | mm | ||||

| A-axis | 10 | sec | ||||

| C axis | 10 | sec | ||||

| Rov ua dua qhov tseeb | X axis | 0.005 ib | mm | |||

| Y axis | 0.005 ib | mm | ||||

| Z axis | 0.005 ib | mm | ||||

| A-axis | 6 | sec | ||||

| C axis | 6 | sec | ||||

| Tshuab loj | 1830 × 3800 × 3050 hli | mm | ||||

| Tshuab hnyav | 6700 ib | kg | ||||

Configuration List

Txuj

| 1 | i5 CNC system | 10 | Cradle Turntable |

| 2 | 20 lub kaus mom zoo li rab riam magazine | 11 | Centralized tsis siv neeg pub mis lubrication system |

| 3 | Tshuab cuab yeej teeb pom kev ua haujlwm teeb | 12 | kev tiv thaiv tag nrho |

| 4 | Spindle taper qhov huv si | 13 | Peb xim ceeb toom teeb |

| 5 | huv si phom | 14 | cua txias |

| 6 | Chip Fluid System | 15 | saw saw saw conveyor |

| 7 | 12 "xim kov npo zaub | 16 | Spindle taper qhov: BT40 7/24 |

| 8 | random technical ntaub ntawv | 17 | Foundation pads thiab kho bolts |

| 9 | 12000 rpm spindle | 18 | Tshuab txaj hlau |

| 19 | Ib phau ntawv qhia lub tshuab (nrog rau cov qauv duab, daim duab kos duab, lub hauv paus daim duab, thiab lwm yam) | 20 | Ib phau ntawv qhia hluav taws xob (xws li hluav taws xob schematic daim duab thiab daim duab thaiv) |

| 21 | Ib phau ntawv kho qhov chaw | 22 | Daim ntawv pov thawj ntawm conformity |

| 23 | Ib daim qauv ntawm cov ntawv ntim khoom |

| Tsis muaj. | Yam khoom | Hom |

| 1 | Hluav taws xob spindle | CTB |

| 2 | txaj turntable | CTB |

| 3 | ntsia hlau bearing | NSK/NWS |

| 4 | Cov Lus Qhia Linear | THK |

| 5 | Tool magazine | Taiwan |

| 6 | twj tso kua mis txias | Kauslim |

| 7 | Lubrication twj tso kua mis | Tuam Tshoj |

| 8 | Pob ntsia hlau | THK |

| 9 | Pneumatic triple | SMC |

| 10 | Main fais fab hloov | Siemens |

| 11 | tus contactor | Siemens |

| 12 | relay | OMPON |

Spindle motor zog torque daim duab

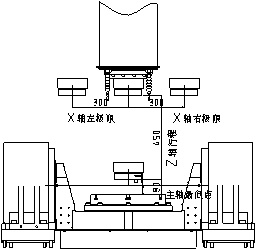

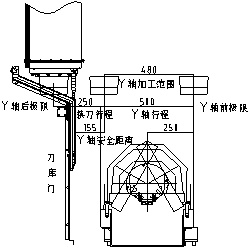

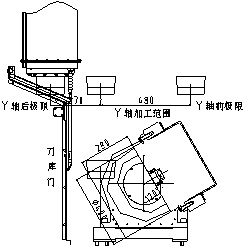

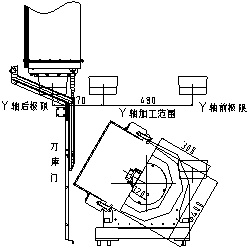

Kev ua ntau yam

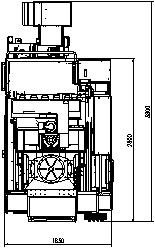

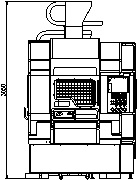

Tshuab qhov ntev thiab layout

Ua tsaug rau koj mloog!